Chevrolet Equinox Service Manual: #11-00-89-007C: Warranty Administration - Revised Exterior Labor Operations (Labor Only-No Part Replaced) and Required Warranty Claim Submission Information...

| Subject: | Warranty Administration - Revised Exterior Labor Operations (Labor Only - No PartReplaced) and Required Warranty Claim Submission Information |

|

| Models: | 2014 and Prior GM Passenger Cars and Light Duty Trucks | |

This bulletin is being revised to add the 2014 model year and update the Labor OperationList. Please discard Corporate Bulletin Number 11-00-89-007B (Section 00 – GeneralInformation).

InstructionsFor the Exterior Labor Operations listed below, on customer complaint issues thatare repaired by labor only (and no part replacement is necessary), please use theClaim Submission Chart (at bottom of bulletin) to create a 10 digit alpha/numericcode to be entered into the Labor Code Dependency Field.

Warranty Claim Administrators:

Enter the labor operations as usual. Enter the 10 digit alpha/numeric code in theLabor Code Dependency Field with no spaces between the characters. Refer to the examplesbelow that explain how to generate the codes.

Note:During the initial few weeks of this change, please enter the requested code in theCorrection Field until the field is enabled in Global Warranty Management (GWM). Onceenabled in GWM, it may take a few weeks for the independent suppliers to have the“Labor Code Dependency Field” turned on for these labor operations in their applications.If you receive a claim reject stating that this information was missing,you can use the GWM website to submit the required claim information.

Labor Operation List:

1411232 Front Side Door Adjustment1412512 Rear Side Door Adjustment1440244 Front Bumper Fascia Color/Clear Coat1410052 Hood Adjustment1420452 Front Bumper Alignment1440254 Front Bumper Fascia Refinish/Clear Coat1414632 Liftgate Adjustment1414092 Rear Compartment Lid Adjustment1445654 Rear Bumper Fascia Refinish/Clear Coat1420122 Front Bumper Fascia AlignmentThis 10 digit alpha/numeric code is designed to aid in making warranty claim processingmore efficient by giving more detailed information for issue problem solving and reducethe need for extensive verbiage and inclusion of pictures on the job card by the technicianand warranty administrator.

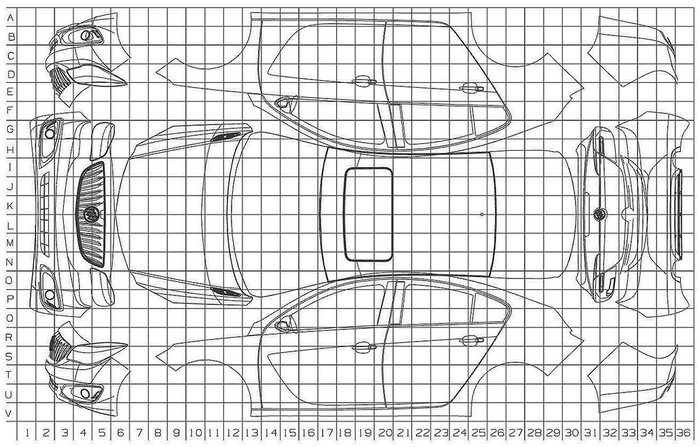

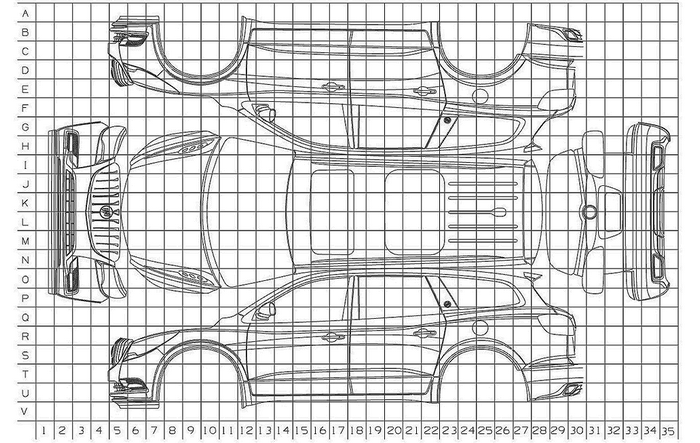

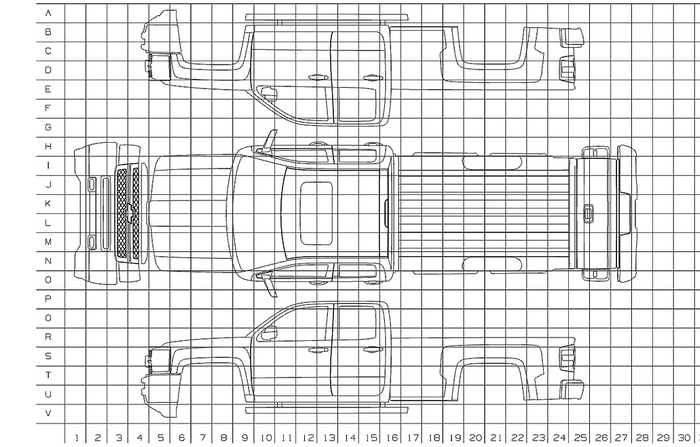

Use the appropriate graphic below to document the specific location of the customerconcern:

Example 1:

Customer complaint on a Buick Regal that the hood has an excessive gap 7-mm (0.275-in)on the front driver’s side that is repaired by correctly adjusting the hood, and nopart was replaced. Using the Claim Submission Chart columns below, the 10 digit alpha/numericcode to be entered into the Labor Code Dependency Field would be CO06010007 (referenced below):

Vehicle Grid = C (for Car)Location on Grid = O06 (area of complaint on grid)Customer Issue = 01 (for fit/gap issue)Issue size (front to back) = 00 (measured gap)Issue size (up/down) = 07 (measured gap)Example 2:Customer complaint on a Chevrolet Traverse that the rear lower rocker molding on passengerrear is loose/fastener not attached and was repaired by properly attaching the moldingand no part was replaced. Using the Claim Submission Chart columns, the 10 digit alpha/numericcode to be entered into the Labor Code Dependency Field would be SB22170000 (referenced below):

Vehicle Grid = S (for SUV)Location on Grid = B22 (area of complaint on grid)Customer Issue = 17 (for fit/gap issue)Issue size (front to back) = 00 (measured gap)Issue size (up/down) = 00 (measured gap)Claim Submission ChartAppearance | ||||

C – Car | See/Use Specific Vehicle Grid | 01 – Fit (Gap) | 00 - NA | 00 - NA |

S – SUV | — | 02 – Fit (Contact) | 01 – 0 to 1-mm (0 to 0.040-in) | 01 – 0 to 1-mm (0 to 0.040-in) |

T- Truck | — | 03 – Fit (Flush - in-board/out-board) | 02 – 1 to 2-mm (0.040 to 0.079-in) | 02 – 1 to 2-mm (0.040 to 0.079-in) |

— | — | 04 – Fit (Wavy/Uneven) | 03 – 2 to 3-mm (0.079 to 0.118-in) | 03 – 2 to 3-mm (0.079 to 0.118-in) |

— | — | 05 – Fit (Alignment) | 04 – 3 to 4-mm (0.118 to 0.157-in) | 04 – 3 to 4-mm (0.118 to 0.157-in) |

— | — | 06 – Mis Match (Color) | 05 – 4 to 5-mm (0.157 to 0.197-in) | 05 – 4 to 5-mm (0.157 to 0.197-in) |

— | — | 07 – Dirt/Contamination in Paint | 06 – 5 to 6-mm (0.197 to 0.236-in) | 06 – 5 to 6-mm (0.197 to 0.236-in) |

— | — | 08 – Peel/Blister/Bubble | 07 – 6 to 7-mm (0.236 to 0.275-in) | 07 – 6 to 7-mm (0.236 to 0.275-in) |

— | — | — | 08 – Greater than 7-mm (0.275-in) | 08 – Greater than 7-mm (0.275-in) |

Function/Performance | ||||

— | — | 09 – Leak (Water) | — | — |

— | — | 10 – Wind Noise | — | — |

— | — | 11 – Noise (Rattle/Other) | — | — |

— | — | 12 – Open/Closing Efforts | — | — |

Damage | ||||

— | — | 13 - Scratch | — | — |

— | — | 14 - Chip | — | — |

— | — | 15 - Dent | — | — |

Other | ||||

— | — | 16 – Missing (Part/Fastener) | — | — |

— | — | 17 – Loose (Part/Fastener) | — | — |

GM bulletins are intended for use by professional technicians,NOT a "do-it-yourselfer". They are written to inform thesetechnicians of conditions that may occur on some vehicles, or toprovide information that could assist in the proper service of avehicle. Properly trained technicians have the equipment,tools, safety instructions, and know-how to do a job properly andsafely. If a condition is described, DO NOT assume that thebulletin applies to your vehicle, or that your vehicle will havethat condition. See your GM dealer for information on whetheryour vehicle may benefit from the information. |

| WE SUPPORT VOLUNTARY TECHNICIAN CERTIFICATION |

#06-00-89-026L: Warranty Administration - Revised Customer Concern Not Duplicated (CCND)/Verified Labor Operation Numbers/How to Submit CCND Transactions...

#06-00-89-026L: Warranty Administration - Revised Customer Concern Not Duplicated (CCND)/Verified Labor Operation Numbers/How to Submit CCND Transactions...

Subject:Warranty Administration – Revised Customer Concern Not Duplicated (CCND) / VerifiedLabor Operation Numbers/How to Submit CCND Transactions in Global Warranty ManagementModels: 2014 and Prio ...

#10-00-89-005C: Warranty Administration - Revised Wiring Repair Labor Operations and Required Additional Information - (May 7, 2013)

#10-00-89-005C: Warranty Administration - Revised Wiring Repair Labor Operations and Required Additional Information - (May 7, 2013)

Subject:Warranty Administration – Revised Wiring Repair Labor Operations and Required AdditionalInformationModels: 2014 and Prior GM Passenger Cars and Light Duty Trucks This bulletin is being r ...

Other materials:

Tire Pressure Indicator Sensor Learn TPMS

Special ToolsEL-46079 Tire Pressure Monitor Diagnostic ToolEL-50448 Tire Pressure Monitor Sensor Activation ToolFor equivalent regional tools, refer toSpecial Tools.Learn Mode DescriptionThe tire pressure monitor system uses the instrument cluster, body control module(BCM), 4-radio frequency transmi ...