Chevrolet Equinox Service Manual: Rear Mud Flap Package Installation Moldings

Installation Instructions Part Number

19202379

Note:Please read instructions thoroughly before starting.

1 | 1 | Left Hand Mud Flap |

2 | 1 | Right Hand Mud Flap |

3 | 6 | #10 Spring Clips |

4 | 6 | #10 x 3/4” Screws |

5 | 2 | Alcohol Wipes |

7 | Installation Instructions |

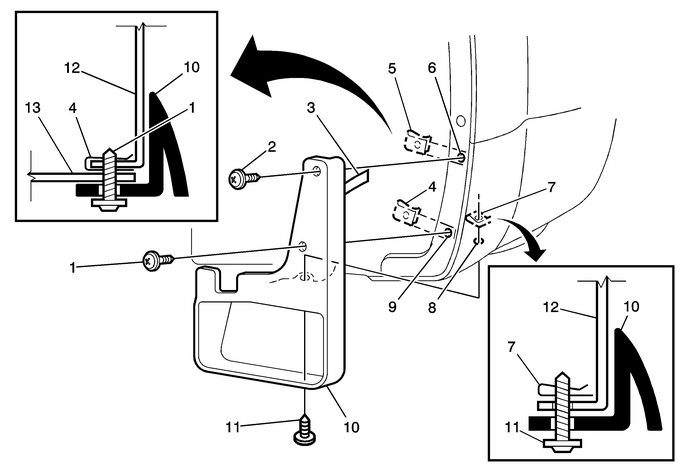

Clean and degrease body panel-(12) where rear mudflaps-(10) are to be located.Using 50% alcohol and water, clean area to be taped.

Note:Parts and vehicle temperature must be between 61°Fand 86°F (16°C and 31°C).

Remove existing push-pin from mountinghole-(9)Note:Install supplied spring clips with turned up edge on insideof panel edge.

Pull liner-(13) forward and install suppliedspring clip-(4) over mountinghole-(9).Mount rear mud flap-(10) and position inner tabbehind liner-(13). Installed suppliedscrew-(1) to mounting hole-(9), while holdingrear mud flap-(10) up and into bodypanel-(12).While holding rear mud flap-(10) firmly againstbody panel-(12), mark and drill ¼”(6.2mm) mounting holes in location-(6),(8), use rear mudflap-(10) as template.Install supplied screws-(2),(11) to mountingholes-(6),(8), use spring clips-(5),(7) asnuts. Tighten screws-(1),(2),(11) while holding rear mudflap-(10) firmly against bodypanel-(12).Push rear mud flap-(10) forward and pull tapeliner off using tab-(3) and apply twenty to thirtypounds of pressure along tape length to ensure contact.Repeat procedure for other side.Note:Mud flaps can be cleaned with any commercially availablecleaner.

Front Fender Mud Flap Package Installation Moldings

Front Fender Mud Flap Package Installation Moldings

Installation Instructions Part Number19171148Note:Please read instructions thoroughly before starting.Front Fender Mud Flap Kit ContentsItem No.QtyDescription11Left Hand Mud Flap21Right Hand Mud Flap3 ...

Liftgate Hinge Replacement Panels

Liftgate Hinge Replacement Panels

Liftgate Hinge ReplacementCalloutComponent NamePreliminary ProceduresRemove the liftgate. Refer toLiftgate Replacement.Lower the rear of the headliner to access the inner bolts.Refer toHeadlining Trim ...

Other materials:

Throttle Body Cleaning Engine Control Air Metering/Acceleration Throttle

Note:Over extended time and mileage, deposits may accumulate on the back of the throttlevalve plate. The source of the deposit is exhaust gas recirculation (EGR) gas. Typicallythese deposits pose no problem. Occasionally the deposit may accumulate to a pointwhere perceived pedal effort or throttle v ...