Chevrolet Equinox Service Manual: Piston, Connecting Rod, and Bearing Cleaning and Inspection Engine Block Cylinder Block Piston Assembly

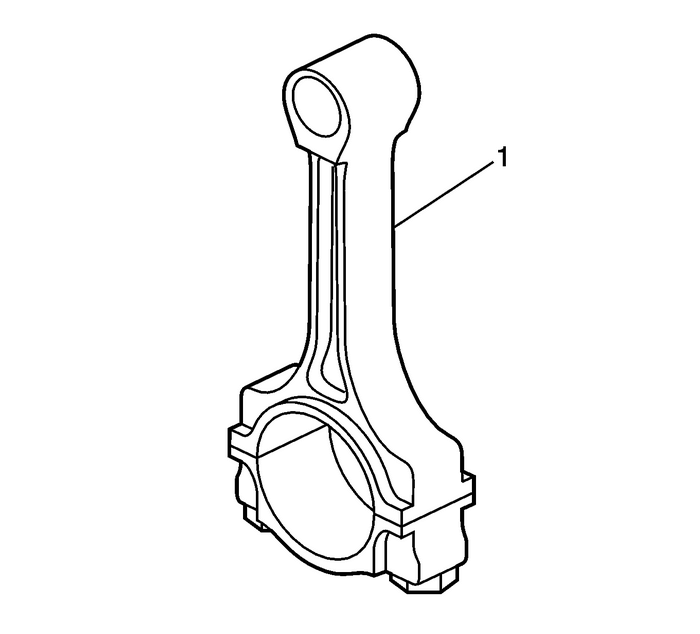

Connecting Rod Measurement

Clean the connecting rods-(1) in solvent and drywith compressed air.Inspect the connecting rods for the following:Signs of being twisted, bent, nicked, or crackedScratches or abrasion on the rod bearing seatingsurfaceIf the connecting rod bores contain minor scratches orabrasions, clean the bores in a circular direction with a lightemery paper. DO NOT scrape the rod or rod cap.If the beam of the rod is scratched or has other damagereplace the connecting rod.Measure the piston pin to connecting rod bore using thefollowing procedure:Using an outside micrometer, take two measurements of thepiston pin in the area of the connecting rod contact.Using an inside micrometer, measure the connecting rod pistonpin bore.Subtract the piston pin diameter from the piston pin borediameter.The clearance should not be more than 0.021-mm(0.0008-in).If there is excessive clearance, replace the pistonpin.If there is still excessive clearance, replace the connectingrod.Piston Measurement

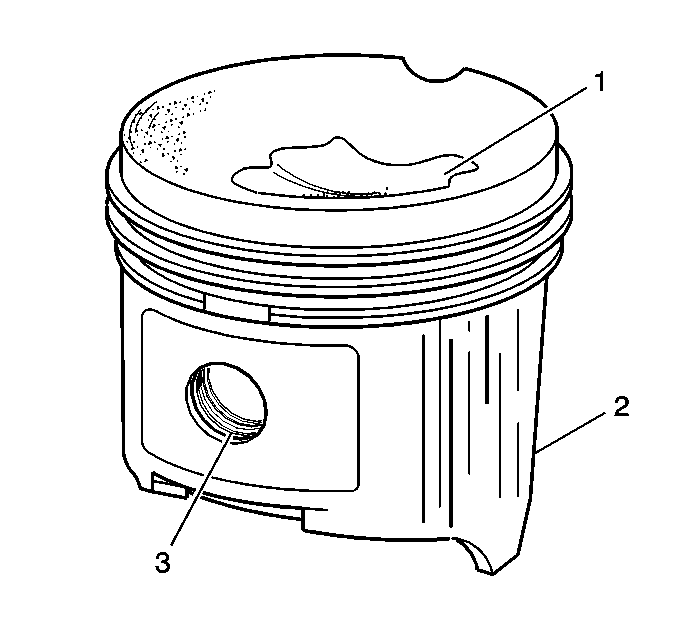

Clean the piston skirts and the pins with a cleaning solvent.DO NOT wire brush any part of the piston.Clean the piston ring grooves with a groove cleaner. Makesure oil ring holes and slots are clean.Inspect the pistons for the following conditions:Cracked ring lands, skirts, or pin bossesRing grooves for nicks, burrs that may cause bindingWarped or worn ring landsEroded areas at the top of the piston (1)Scuffed or damaged skirts (2)Worn piston pin bores (3)Replace pistons that show any signs or damage or excessivewear.Measure the piston pin bore to piston pin clearances usingthe following procedure:Piston pin bores and pins must be free of varnish orscuffing.Use an outside micrometer to measure the piston pin in thepiston contact areas.Using an inside micrometer, measure the piston pinbore.Subtract the measurement of the piston pin bore from thepiston pin. The clearance should be within0.002–0.012-mm(0.00007–0.00047-in).If the clearance is excessive, determine which component isout of specification.

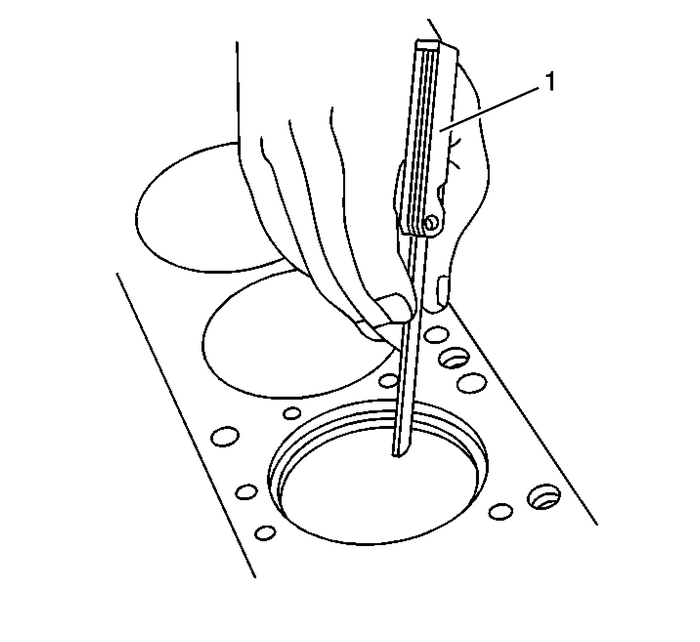

Measure the piston ring end gap using the followingprocedure:Place the piston ring in the area of the bore where thepiston ring will travel (approximately 25-mm or1-inch down from the deck surface). Be sure the ring issquare with the cylinder bore by positioning the ring with thepiston head.Measure the end gap of the piston ring with feelergauges-(1). Compare the measurements with those providedbelow:The top compression ring end gap should be0.20–0.40-mm(0.0060–0.015-in).The second compression ring end gap should be0.35–0.55-mm(0.0137–0.0216-in).The oil ring end gap should be0.25–0.76-mm(0.0098–0.029-in).If the clearance exceeds the provided specifications, thepiston rings must be replaced.Repeat the procedure for all the piston rings.

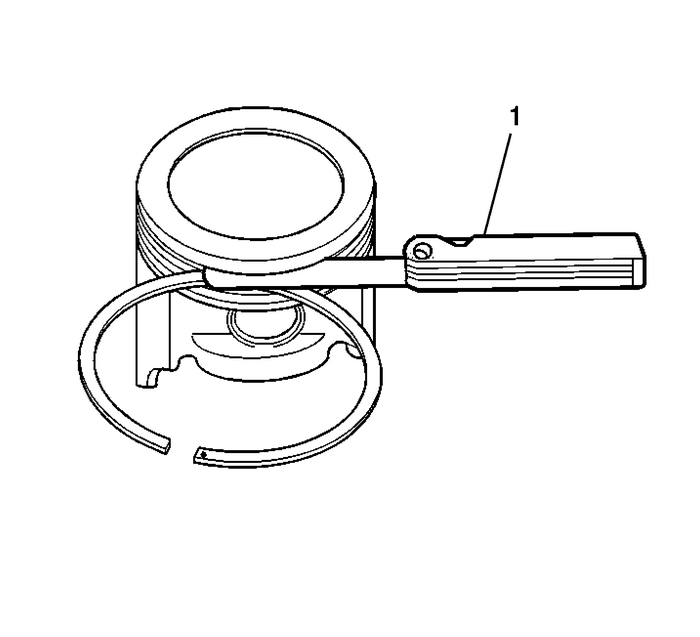

Measure the piston ring side clearance using the followingprocedure:Roll the piston ring entirely around the piston ring groove.If any binding is caused by a distorted piston ring, replace thering.With the piston ring on the piston, use feelergauges-(1) to check clearance at multiplelocations.The clearance between the surface of the top piston ring andthe ring land should be no greater than 0.075-mm(0.0030-in).If the clearance is greater than specifications, replace thepiston ring.If the new ring does not reduce the top ring side clearanceto 0.075-mm (0.0030-in) or less, install anew piston.The top compression ring may be installed with either sideup. There is a locating dimple on the 2nd compression ring near theend for identification of the top side. Install the 2nd compressionring with the dimple facing up.The clearance between the surface of the second piston ringand the ring land should be no greater than 0.069-mm(0.0026-in).If the new ring does not reduce the clearance to0.069-mm (0.0026-in) or less, install a newpiston.

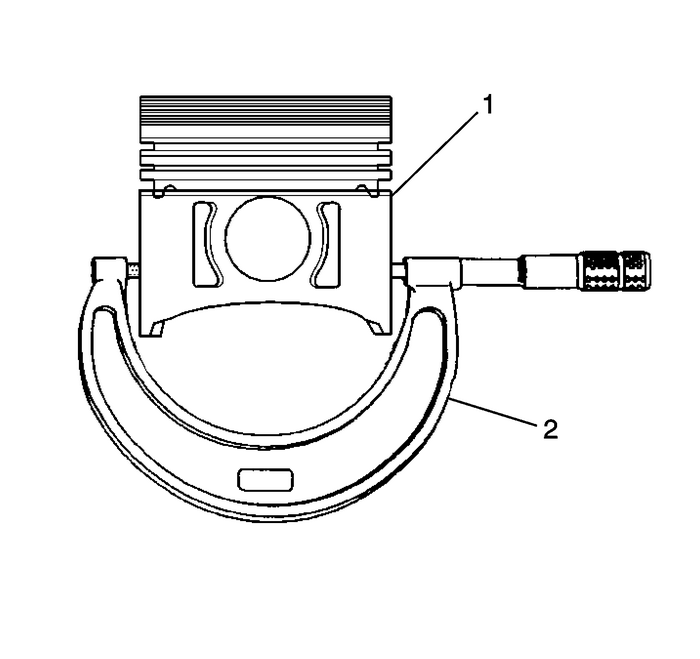

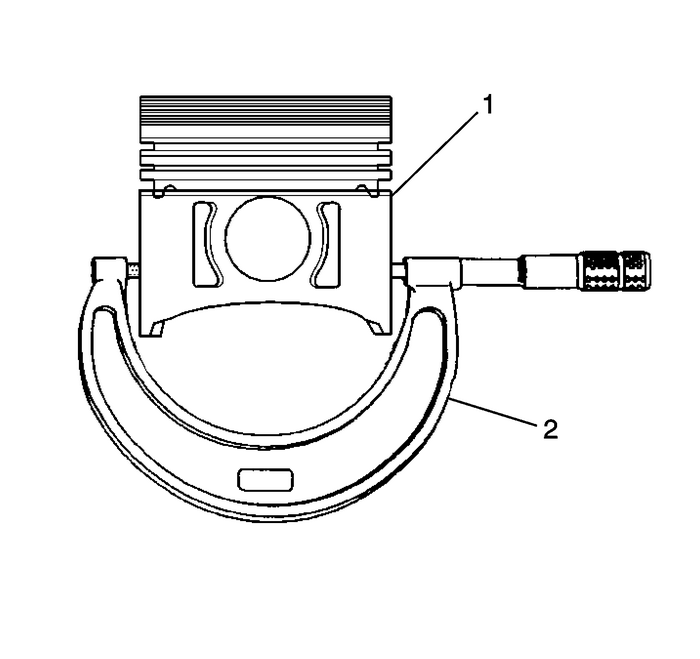

Measure piston width using the following procedure:Using an outside micrometer-(2), measure the widthof the piston 14.5-mm (0.570-in) above thebottom of the piston skirt at the thrust surface perpendicular tothe centerline of the piston pin.Compare the measurement of the piston to its originalcylinder by subtracting the piston width from the cylinderdiameter.The proper clearance specification for the piston is0.010–0.041-mm(0.0006–0.0016-in).If the clearance obtained through measurement is greater thanthese specifications and the cylinder bores are withinspecification, replace the piston-(1).Piston Selection

Note:Measurements of all components should be taken with thecomponents at normal room temperature.

For proper piston fit, the engine block cylinder bores mustnot have excessive wear or taper.

A used piston and pin set may be reinstalled if, aftercleaning and inspection, they are within specifications.

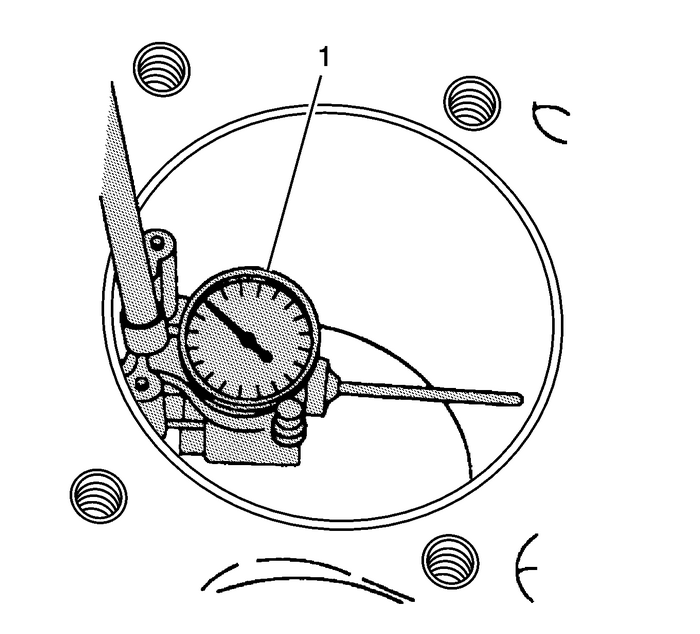

Inspect the engine block cylinder bore. Refer toEngine Block Cleaning and Inspection.Inspect the piston and the piston pin.Use a bore gauge-(1) and measure the cylinder borediameter. Measure at a point 64-mm (2.5-in)from the top of the cylinder bore.

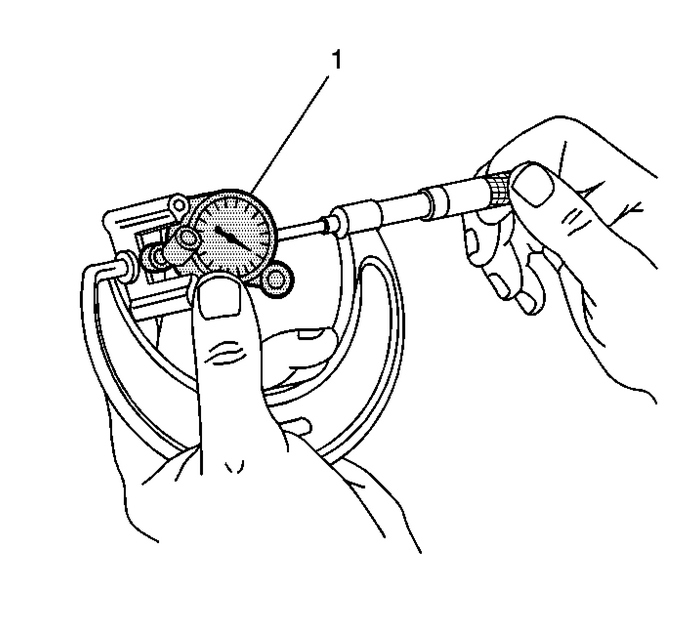

Measure the bore gauge with a micrometer-(1) andrecord the reading.

With a micrometer-(2) or caliper at a right angleto the piston-(1), measure the piston 14-mm(0.570-in) from the bottom of the skirt.Subtract the piston diameter from the cylinder bore diameterin order to determine piston-to-bore clearance.For proper piston-to-bore clearance. Refer toEngine Mechanical Specifications.If the proper clearance cannot be obtained, select anotherpiston and measure for the clearances.If the proper fit cannot be obtained, hone the cylinder boreor replace the cylinder block.When the piston-to-cylinder bore clearance is withinspecifications, mark the top of the piston using a permanent markerfor installation to the proper cylinder. Refer toSeparating Parts.

Oil Pan Cleaning and Inspection Engine Lubrication Oil Sump/Pan

Oil Pan Cleaning and Inspection Engine Lubrication Oil Sump/Pan

Clean the oil pan mating surface.Clean the oil pan-(1). Remove all the sludge andthe oil deposits.Inspect the threads for the engine oil drain plug.Inspect the oil pan for cracking near the pan rail a ...

Coolant Heater Cord Replacement (LEA) Engine Cooling

Coolant Heater Cord Replacement (LEA) Engine Cooling

Coolant Heater Cord ReplacementCalloutComponent NamePreliminary ProcedureLift and support the vehicle. Refer toLifting and Jacking the Vehicle.1Retainers2Coolant Heater Cord ...

Other materials:

Center Pillar Outer Panel Reinforcement Replacement

Removal ProcedureDisable the SIR System. Refer toSIR Disabling and Enabling.Disconnect the negative battery cable. Refer toBattery Negative Cable Disconnection and Connection.Warning:Refer toApproved Equipment for Collision Repair Warning.Note:The service B-Pillar will come as a completeassembly and ...