Chevrolet Equinox Service Manual: Piston, Connecting Rod, and Bearing Cleaning and Inspection Engine Block Cylinder Block Piston Assembly

Cleaning Procedure

Note:DO NOT wire brush any part of the piston.

Clean the piston skirts and the pins with a cleaningsolvent.Clean the piston ring grooves with a groove cleaner. Ensurethat the oil ring holes and slots are clean.Warning:Refer toSafety Glasses Warning.

Dry the piston with compressed air.Piston Inspection Procedure

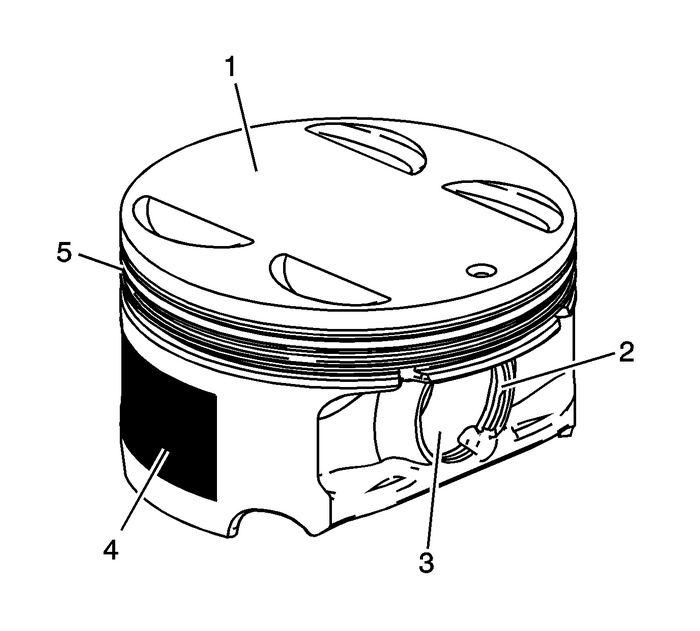

Inspect the pistons for the following conditions:Cracked ring lands, skirts or pin bossesRing grooves for nicks, burrs that may causebinding-(5)Warped or worn ring lands-(5)Piston pin retainer grooves for burrs-(2)Eroded areas at the top of the piston-(1)Scuffed or damaged skirt coating-(4)Worn piston pin bores or worn pistonpins-(3)Replace pistons that show any signs of damage or excessivewear.Piston Measurement Procedure

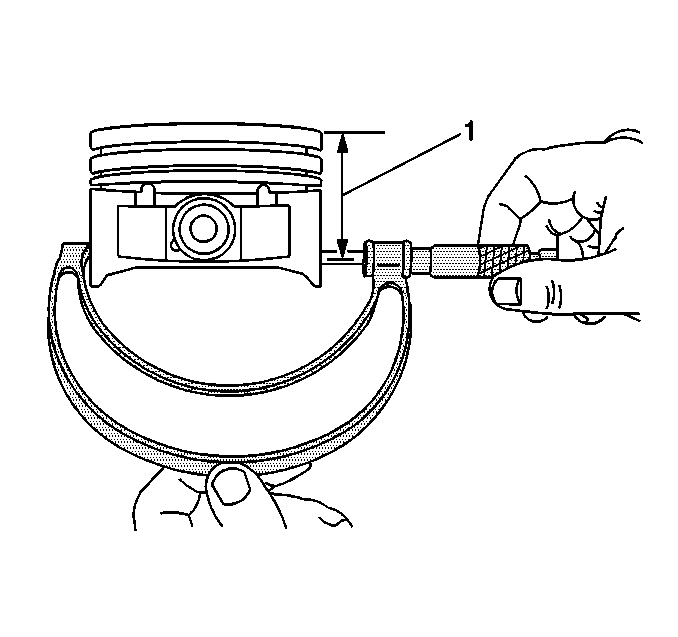

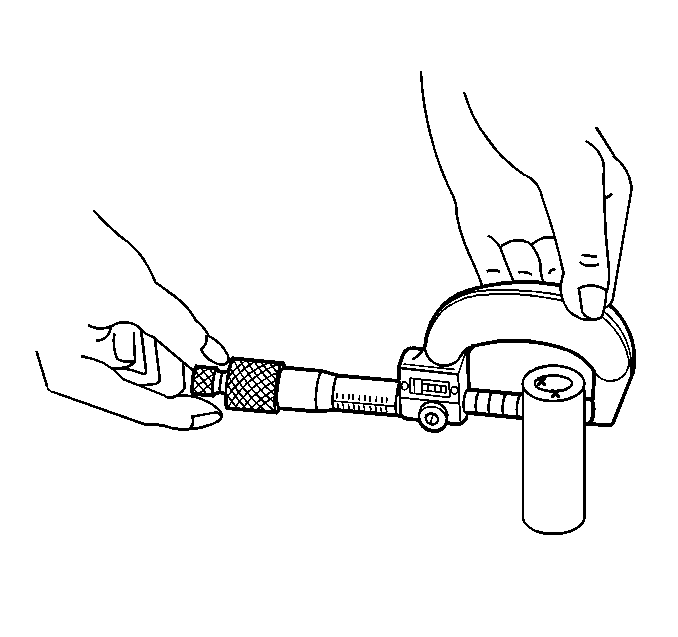

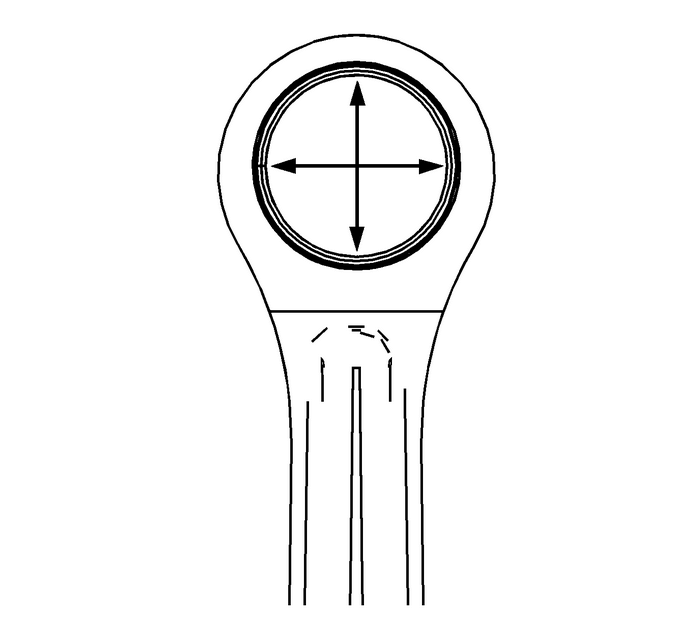

Measure piston width using the following procedure:Using an outside micrometer, measure the width of the pistonat 30-mm (1.181-in) below the crown,top-(1), at the thrust surfaces of the piston,perpendicular to the piston pin centerline.Compare the measurement of the piston to its originalcylinder by subtracting the piston width from the cylinderdiameter.Check your measurements with theEngine Mechanical Specifications.If the clearance obtained through measurement is greater thanthe provided specifications and the cylinder bores are withinspecification, replace the piston.

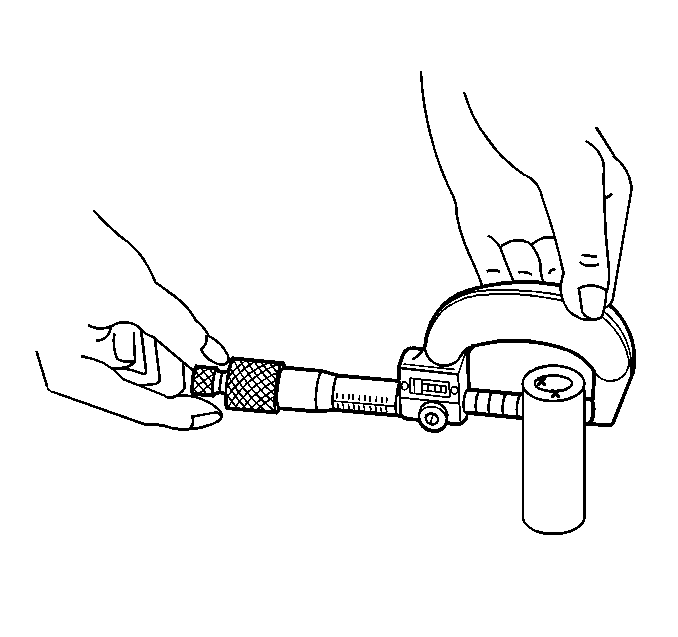

Measure the piston pin bore to piston pin clearances usingthe following procedure:Piston pin bores and pins must be free of varnish orscuffing.Use an outside micrometer to measure the piston pin in thepiston contact areas.

Using an inside micrometer, measure the piston pin bore.Compare your result with the piston pin diameter and piston pin topiston pin bore clearance listed in theEngine Mechanical Specifications.If the clearance is excessive, determine which piece is outof specification and replace as necessary.You must replace the piston if any of its dimensions are outof specification.If the new piston does not meet clearance specifications, thecylinder block may need to be oversized to 0.25-mm(0.010-in). There is only one size of oversized pistonsand rings available for service.Piston Ring Measurement Procedure

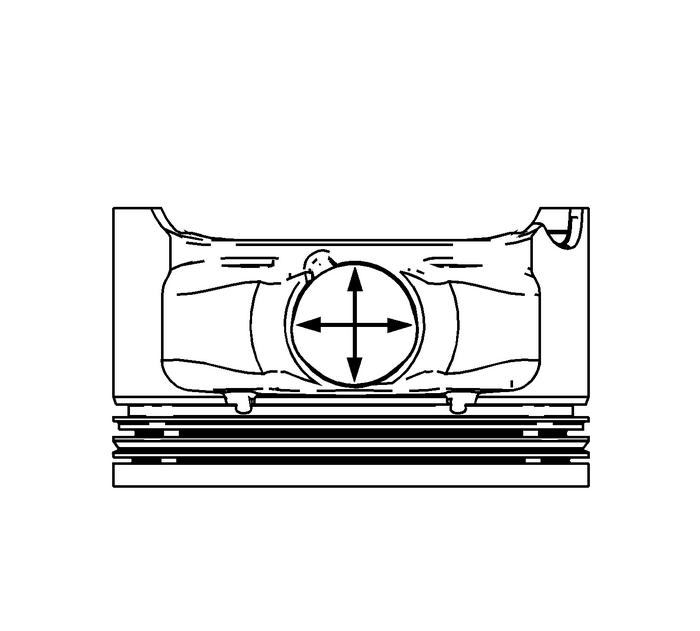

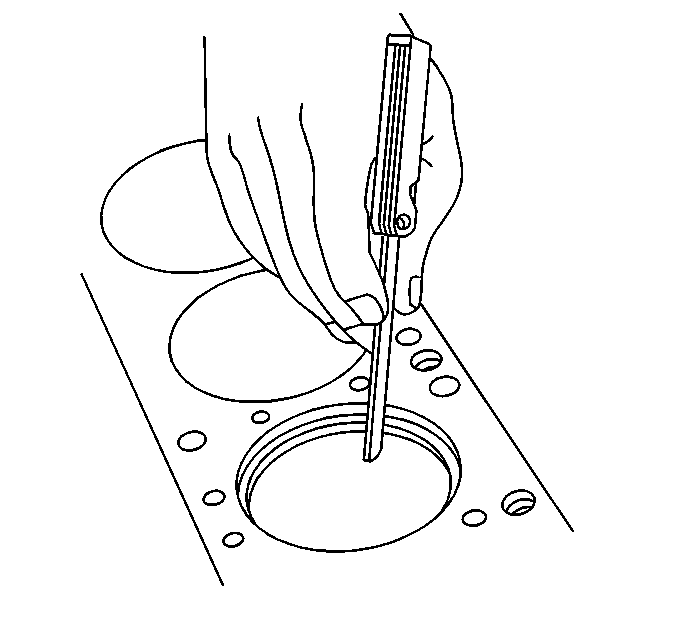

Measure the piston ring end gap using the followingprocedure:Place the piston ring in the area of the bore where thepiston ring will travel approximately 25-mm(1-in) down from the deck surface. Ensure that the ringis square with the cylinder bore by positioning the ring with thepiston head.Measure the end gap of the piston ring with feeler gauges.Refer toEngine Mechanical Specifications.If the clearance exceeds the provided specifications, thepiston rings must be replaced.Repeat the procedure for all the piston rings.

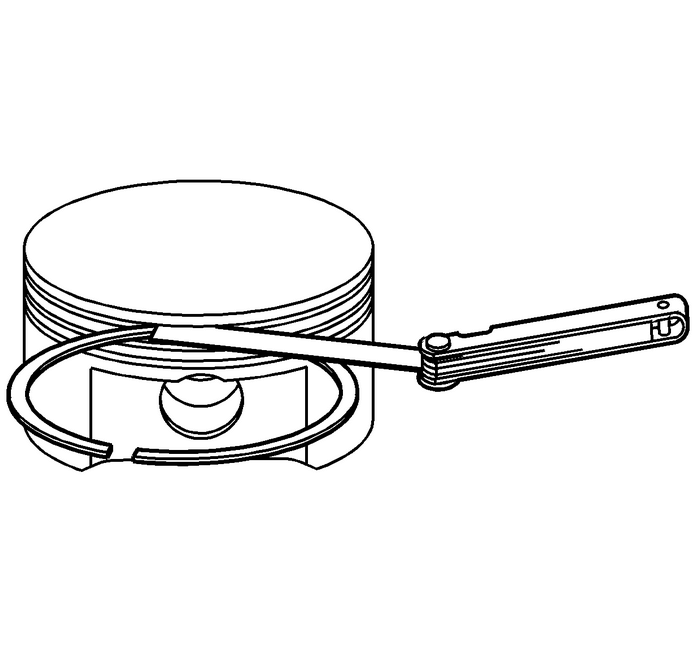

Measure the piston ring side clearance using the followingprocedure:Roll the piston ring entirely around the piston ring groove.If any binding is caused by the ring groove, dress the groove witha fine file. If any binding is caused by a distorted piston ring,replace the ring.With the piston ring on the piston, use feeler gauges tocheck clearance at multiple locations.Compare the measurements with piston ring side clearancelisted in theEngine Mechanical Specifications.If the clearance is greater than specifications, replace thepiston rings.

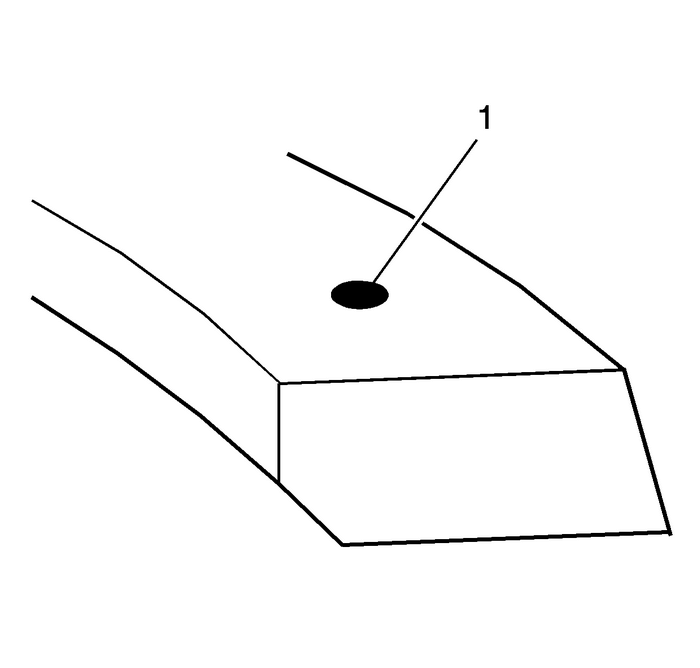

There is a locating dimple-(1) on the compressionrings near the end for identification. Install the compressionrings with the dimple facing up.If the new ring does not reduce the clearance to the properspecification, install a new piston.If the new piston does not meet clearance specifications, thecylinder block may need to be oversized to 0.25-mm(0.010-in). There is only one size of oversized pistonsand rings available for service.Connecting Rod Cleaning ProcedureClean the connecting rods in solvent.

Warning:Refer toSafety Glasses Warning.

Dry the connecting rod using compressed air.Remove the connecting rod cap and clean the threads.Remove the connecting rod bearing and discard. Never reuse aconnecting rod bearing used in a running engine.Connecting Rod Visual Inspection Procedure

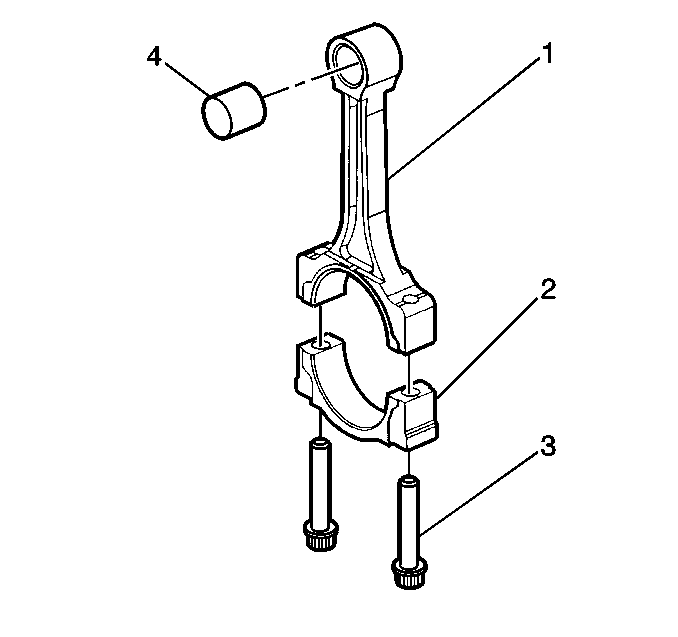

Inspect the piston pin bushing-(4) for scoring ordamage.Inspect the connecting rod beam-(1) for twistingor bending.Inspect the rod cap-(2) for any nicks or damagecaused by possible interference.Inspect for scratches or abrasion on the rod bearing seatingsurface.

Note:DO NOT scrape the rod or rod cap.

If the connecting rod bores contain minor scratches orabrasions, clean the bores in a circular direction with a lightemery paper.Connecting Rod Measurement ProcedurePiston Pin End

Note:Measurements of all components should be taken with thecomponents at normal room temperature.

Using an outside micrometer, take 2-measurementsof the piston pin in the area of the connecting rod contact.

Using an inside micrometer, measure the connecting rod pistonpin bore.Subtract the piston pin diameter from the piston pinbore.Compare the clearance measurements with theEngine Mechanical Specifications.If the clearance is excessive, replace the piston pin. If anew pin does not resolve the clearance problem, replace theconnecting rod.Connecting Rod Crankshaft Bearing End

Note:Measurements of all components should be taken with thecomponents at normal room temperature.

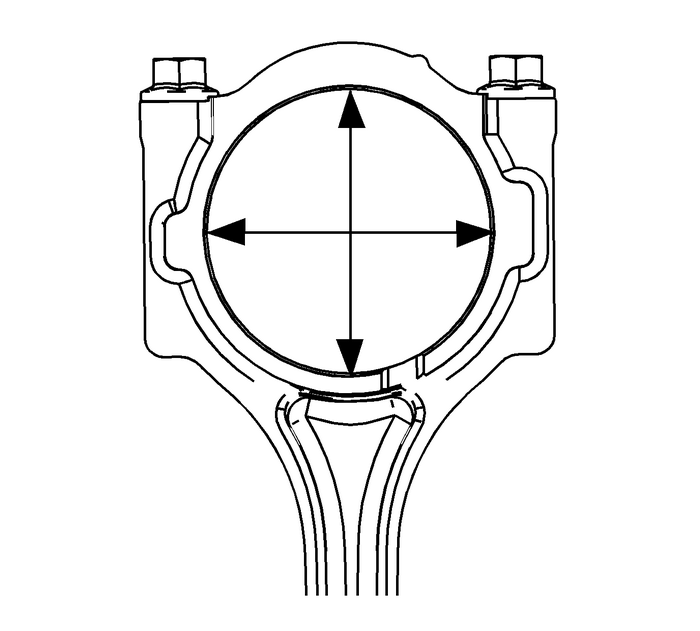

Using an inside micrometer, measure the connecting rodcrankshaft bearing bore.Compare the bore measurements with theEngine Mechanical Specifications.Replace the connecting rod if the bore is out ofspecifications. DO NOT recondition the connecting rod. Oil Pump Suction Pipe and Screen Cleaning and Inspection Engine Lubrication Oil Pump

Oil Pump Suction Pipe and Screen Cleaning and Inspection Engine Lubrication Oil Pump

Cleaning ProcedureClean the oil pump pipe and screen with solvent.Warning:Refer toSafety Glasses Warning.Dry the oil pump pipe and screen with compressed air.Inspection ProcedureInspect the mounting s ...

Balance Shaft Cleaning and Inspection Engine Block Cylinder Block Balance Shaft

Balance Shaft Cleaning and Inspection Engine Block Cylinder Block Balance Shaft

Clean the balance shafts-(1) in solvent.Inspect the bearing surfaces on the balance shafts forscoring or unusual wear.Note:Do not remove the balance shaft drive sprockets.Inspect the balance shaft dri ...

Other materials:

Cylinder Boring and Honing (LAF, LEA, or LUK)

Boring ProcedureMeasure all pistons with a micrometer to determine thecylinder bore diameter. Refer toEngine Block Cleaning and Inspection.Before you use any type of boring bar, use a fine file andclean the top of the cylinder block, removing any dirt or burrs. Ifyou do not check the cylinder block, ...