Chevrolet Equinox Service Manual: Balance Shaft Cleaning and Inspection Engine Block Cylinder Block Balance Shaft

Chevrolet Equinox Service Manual / Powertrain / Engine / Balance Shaft Cleaning and Inspection Engine Block Cylinder Block Balance Shaft

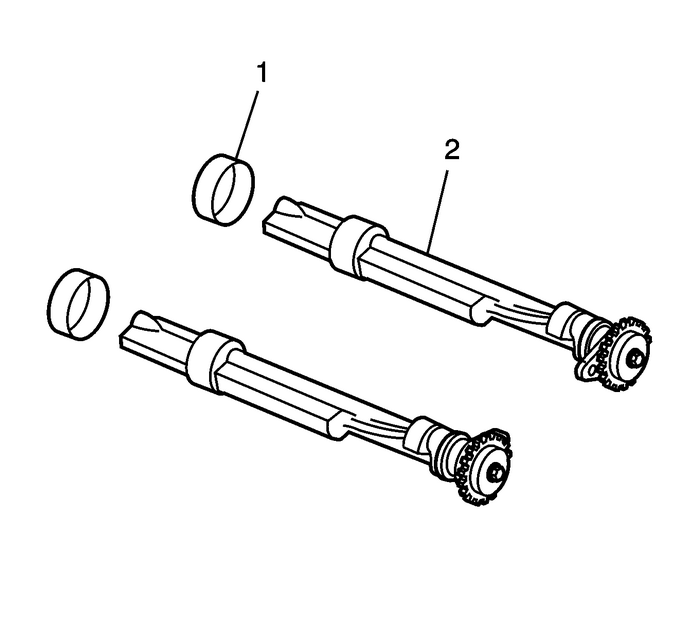

Clean the balance shafts-(1) in solvent.Inspect the bearing surfaces on the balance shafts forscoring or unusual wear.

Note:Do not remove the balance shaft drive sprockets.

Inspect the balance shaft drive sprockets for wear, damage,or missing teeth.Measure the rear bearing journals on the balance shafts, thejournals should be 36.723–36.743-mm(1.4458–1.4466-in) in diameter.Measure the front bearing journals on the balance shafts, thefront bearing journals should be20.020–20.000-mm(0.7881–0.7874-in) in diameter.When the balance shafts have been installed in the engineblock, check for smooth rotation, sticking, binding, orroughness. Piston, Connecting Rod, and Bearing Cleaning and Inspection Engine Block Cylinder Block Piston Assembly

Piston, Connecting Rod, and Bearing Cleaning and Inspection Engine Block Cylinder Block Piston Assembly

Cleaning ProcedureNote:DO NOT wire brush any part of the piston.Clean the piston skirts and the pins with a cleaningsolvent.Clean the piston ring grooves with a groove cleaner. Ensurethat the oil ring ...

Crankshaft Balancer Cleaning and Inspection Engine Block Cylinder Block Crankshaft

Crankshaft Balancer Cleaning and Inspection Engine Block Cylinder Block Crankshaft

Clean the crankshaft balancer-(1).Clean the belt grooves of all dirt or debris with a wirebrush.Warning:Refer toSafety Glasses Warning.Dry the crankshaft balancer with compressed air.Inspect the crank ...

Other materials:

Cooling System

1.5L Gas Engine

Engine Cooling Fan (Out

of View)

Engine Coolant Surge Tank

and Pressure Cap

1.6L Diesel Engine

Engine Cooling Fan (Out

of View)

Engine Coolant Surge Tank

and Pressure Cap

2.0L Gas Engine

Engine Cooling Fan (Out

of View)

...

© 2017-2026 Copyright www.cequinox.com