Chevrolet Equinox Service Manual: Hub/Axle Flange and Wheel Stud Runout Inspection Wheels

Special Tools

GE-8001Dial Indicator Set, or equivalent

Raise and support the vehicle. Refer toLifting and Jacking the Vehicle.Mark the location of the wheels to the wheel studs and markthe specific vehicle position on each tire and wheel –LF, LR, RF, RR.Remove the tire and wheel assemblies from the vehicle. RefertoTire and Wheel Removal and Installation.Remove the brake rotors and/or brake drums from the vehicle.Clean the mounting surfaces of the brake rotors, the brake drums,if equipped, and the hub/axle flanges of any loose debris, rust,and corrosion.

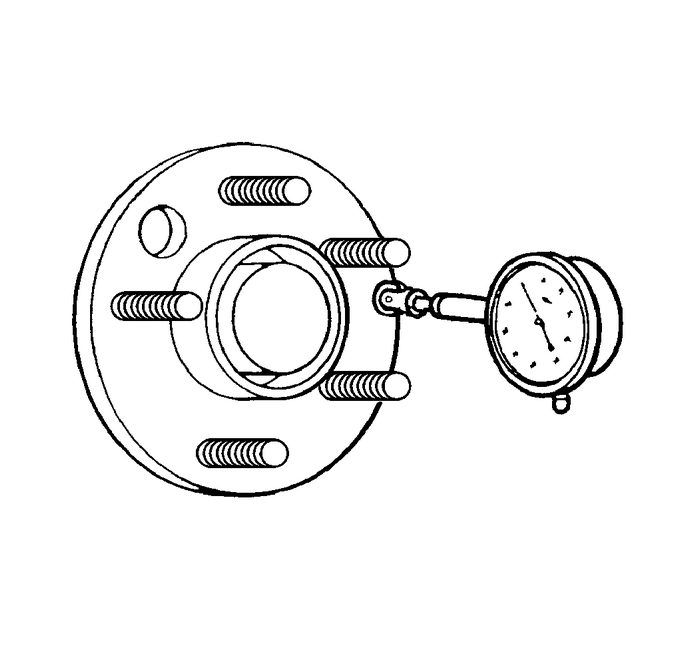

Position theGE-8001Dial Indicator Set, or equivalent, on the machined surface of the wheelhub/axle flange outside of the wheel studs.Rotate the hub one complete revolution in order to find thelow spot.Set theGE-8001Dial Indicator Set, or equivalent, to zero at the low spot.Rotate the hub one more complete revolution and measure thetotal amount of wheel hub/axle flange runout.

Specification – Guideline

Wheel hub/axle flange runout tolerance guideline:0.132-mm (0.005-in)If the runout of the wheel hub/axle flange IS withinspecification and the vehicle is equipped with wheel studs, proceedto step-13.If the runout of the wheel hub/axle flange IS withinspecification and the vehicle is equipped with wheel bolts, proceedto step-19.If the runout of the wheel hub/axle flange is marginal, thewheel hub may or may not be the source of the disturbance.If the runout of the wheel hub/axle flange is excessive,replace the wheel hub/axle flange. Measure the runout of the newwheel hub/axle flange.

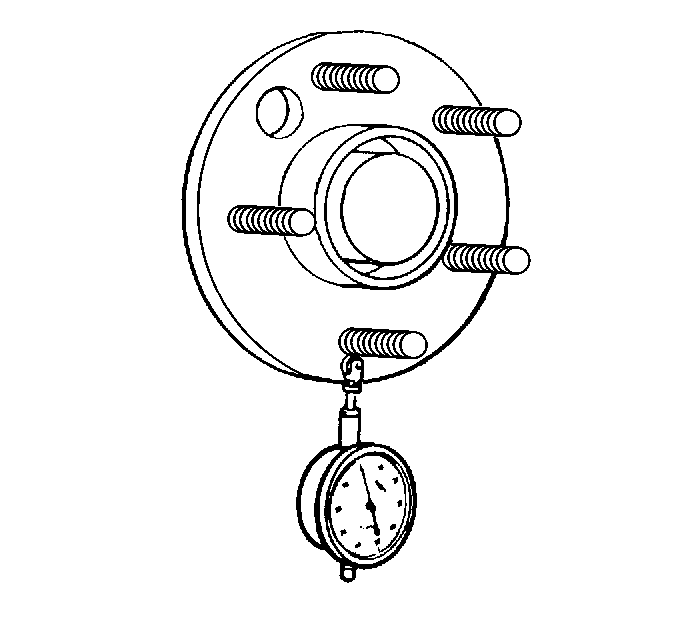

Position theGE-8001Dial Indicator Set, or equivalent, in order to contact the wheel mountingstuds.

Measure the stud runout as close to the flange aspossible.

Turn the hub one complete revolution to register on each ofthe wheel studs.Zero theGE-8001Dial Indicator Set, or equivalent, on the lowest stud.Rotate the hub one more complete revolution and measure thetotal amount of wheel stud – stud circle –runout.Specification – Guideline

Wheel stud runout tolerance guideline: 0.254-mm(0.010-in)If the runout of the wheel studs – stud circle– is marginal, the wheel studs may or may not becontributing to the disturbance.If the runout of the wheel studs – stud circle– is excessive, replace the wheel studs as necessary.Measure the runout of the new wheel studs.Inspect the threads and the tapered seat portion on each ofthe wheel bolts for damage.Wheel bolts exibiting damaged threads and/or damaged taperedseats require replacement.Place the threaded portion of each wheel bolt along astraight edge to inspect for straightness.Wheel bolts that are not straight require replacement.

Tire Pressure Indicator Sensor Learn TPMS

Tire Pressure Indicator Sensor Learn TPMS

Special ToolsEL-46079 Tire Pressure Monitor Diagnostic ToolEL-50448 Tire Pressure Monitor Sensor Activation ToolFor equivalent regional tools, refer toSpecial Tools.Learn Mode DescriptionThe tire pres ...

Front Wheel Drive Shaft Replacement Wheels

Front Wheel Drive Shaft Replacement Wheels

Special ToolsJ-2619-01 Slide HammerJ-42129 Hub PullerJ-45341 Rear Wheel Drive Shaft Removal ToolsFor regional equivalent tools, refer toSpecial Tools.Removal ProcedureRaise and support the vehicle. Re ...

Other materials:

Rear Side Door Garnish Molding Replacement Trim Panels/Welts

Rear Side Door Garnish Molding ReplacementCalloutComponent NamePreliminary ProcedureRemove the rear side door trim panel. Refer toRear Side Door Trim Panel Replacement.1Rear Side Door Garnish Molding RetainerProcedureUse a door trim panel removal tool or equivalent to aid inthe removal of the retain ...