Chevrolet Equinox Service Manual: Front Wheel Drive Shaft Replacement Wheels

Special ToolsJ-2619-01 Slide HammerJ-42129 Hub PullerJ-45341 Rear Wheel Drive Shaft Removal Tools

For regional equivalent tools, refer toSpecial Tools.

Removal ProcedureRaise and support the vehicle. Refer toLifting and Jacking the Vehicle.Remove the tire and wheel assembly. Refer toTire and Wheel Removal and Installation.

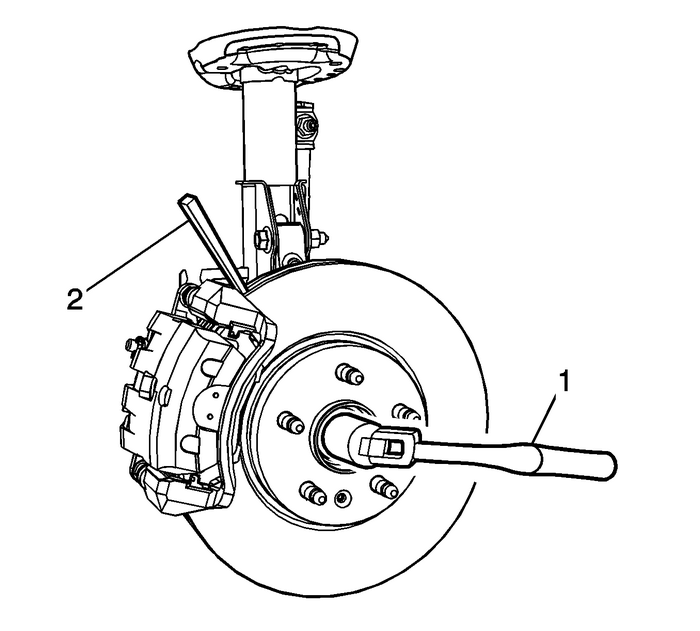

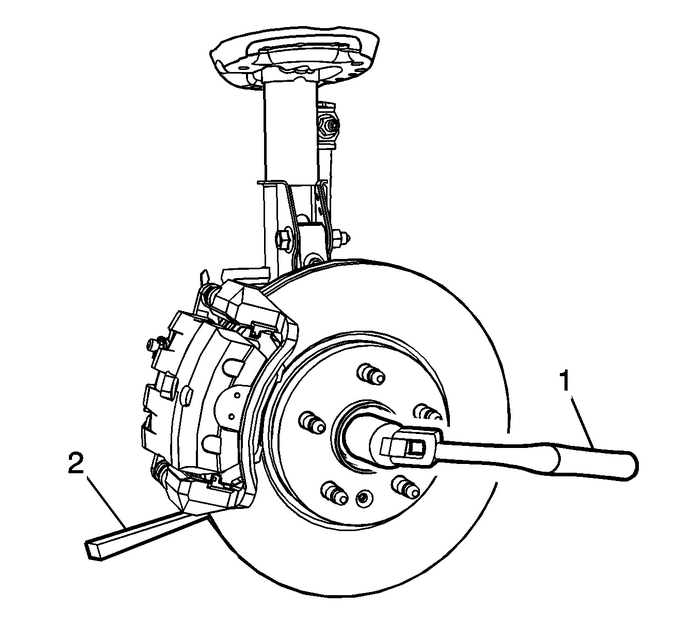

Insert a punch or a drift-(2) in the cooling fins of the brake rotor.Rotate the brake rotor until it rest against the brake caliper mounting bracket.Using a breaker bar and the proper size socket-(1), loosen the wheel drive shaft nut.

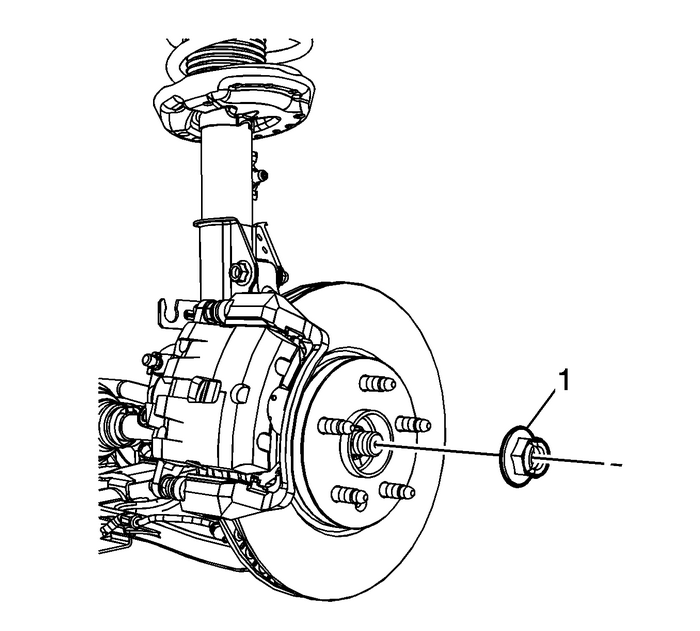

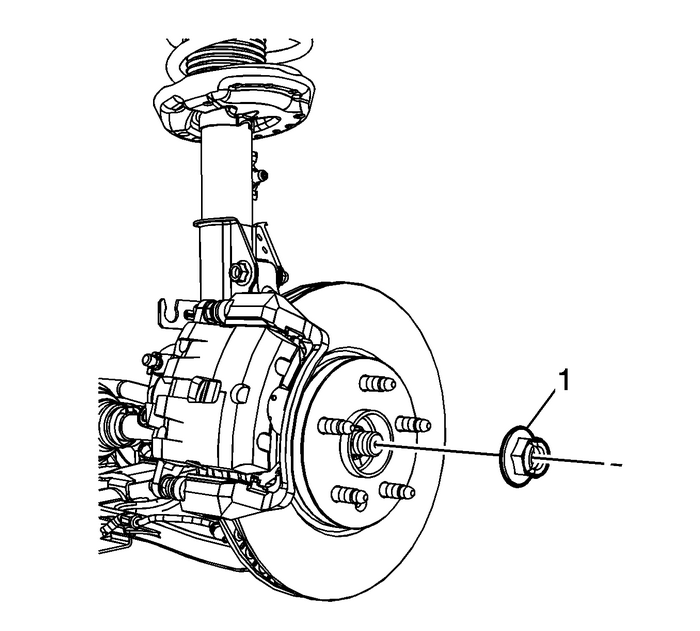

Remove the wheel drive shaft nut-(1) and discard.

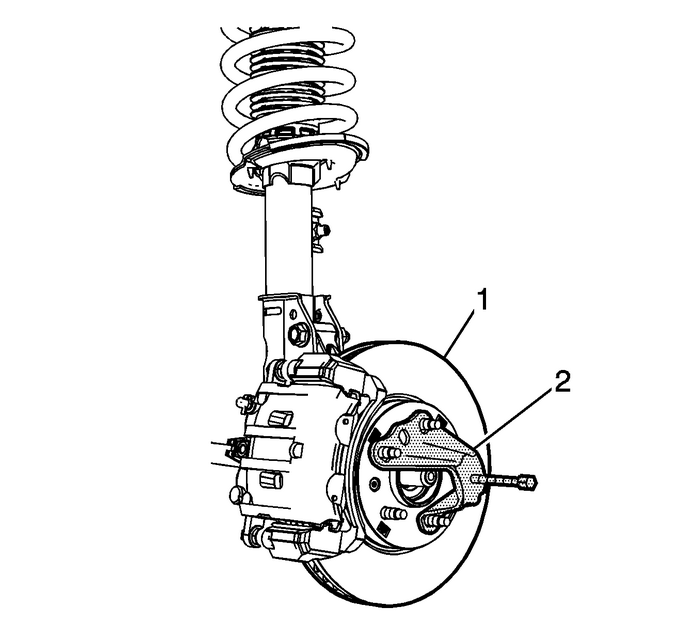

Using the J-42129 puller-(2), separate the wheel drive shaft from the wheel hub-(1).Separate the stabilizer link from the lower control arm. Refer toStabilizer Shaft Link Replacement.Separate the outer tie rod end from the knuckle. Refer toSteering Linkage Outer Tie Rod Replacement.Separate the lower control arm from the knuckle. Refer toLower Control Arm Replacement.

Note:The front axle shaft seal must be replaced once the wheel drive shaft has been removed.Replace with NEW only. DO NOT reuse the front axle shaft seal.

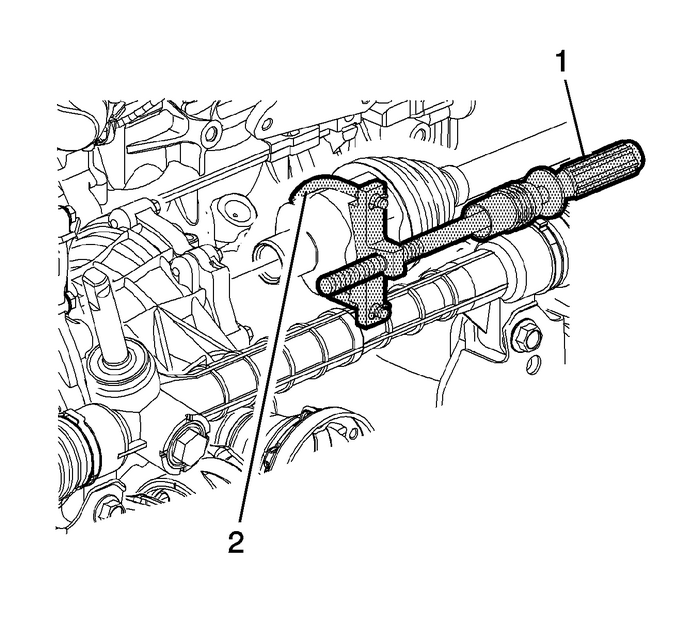

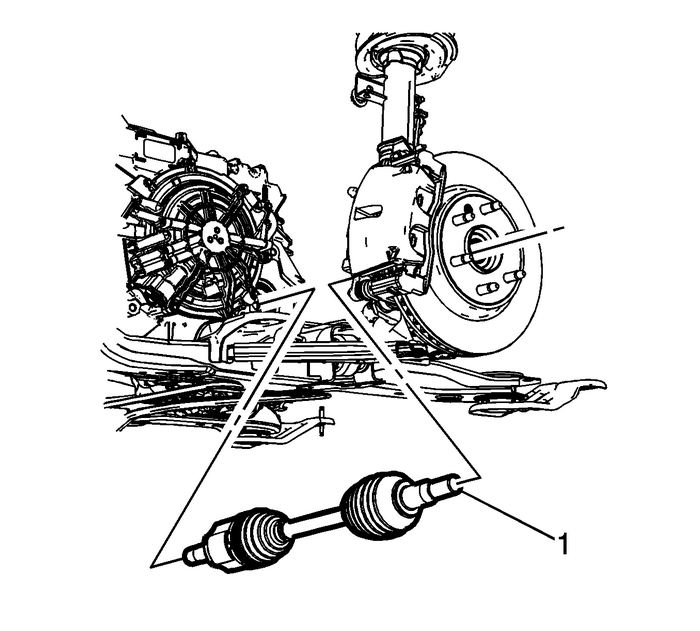

Using the J-2619-01 hammer-(1)-and the J-45341 tool-(2), remove the wheel drive shaft from the vehicle.Installation Procedure

Install the wheel drive shaft-(1).Install the wheel drive shaft in the knuckle.

Hand install a new wheel drive shaft nut-(1).Install the lower ball to the steering knuckle. Refer toLower Control Arm Replacement.Install the lower link to the stabilizer bar. Refer toStabilizer Shaft Link Replacement.Install the tie rod end to the steering knuckle. Refer toSteering Linkage Outer Tie Rod Replacement.

Insert a drift or punch-(2) in the brake rotor cooling fins.Rotate the brake rotor until it rest against the brake caliper mounting bracket.

Caution:Refer toFastener Caution.

Using a torque wrench and the proper size socket-(1), tighten the wheel drive shaftnut to 205-Y (151-lb-ft).Install the tire and wheel assembly. Refer toTire and Wheel Removal and Installation.Lower the vehicle.Inspect the transmission fluid level.For the 6T30/6T40/6T45/6T50 transmission, refer toTransmission Fluid Level and Condition Check.For the 6T70/6T75 transmission, refer toTransmission Fluid Level and Condition Check. Hub/Axle Flange and Wheel Stud Runout Inspection Wheels

Hub/Axle Flange and Wheel Stud Runout Inspection Wheels

Special ToolsGE-8001Dial Indicator Set, or equivalentRaise and support the vehicle. Refer toLifting and Jacking the Vehicle.Mark the location of the wheels to the wheel studs and markthe specific vehi ...

Rear Wheel Drive Shaft Inner Joint and Boot Replacement Wheels

Rear Wheel Drive Shaft Inner Joint and Boot Replacement Wheels

Special ToolsJ-35910Drive Axle Boot Clamp PliersNote:The inner Constant Velocity Joint is not serviced separately.If the CV joint is found to have excessive wear or damaged, replacethe wheel drive sha ...

Other materials:

Arming the Alarm System

Turn off the vehicle.

Lock the vehicle in one of

three ways:

Use the RKE transmitter.

With a door open, press the

interior .

After 30 seconds the alarm

system will arm, and the

indicator light will begin to

slowly flash indicating the

alarm syst ...