Chevrolet Equinox Service Manual: Front Differential Drive Pinion Bearing Cup, Washer, and Lubricant Dam Replacement - Torque Converter Housing Side Automatic Transmission Unit

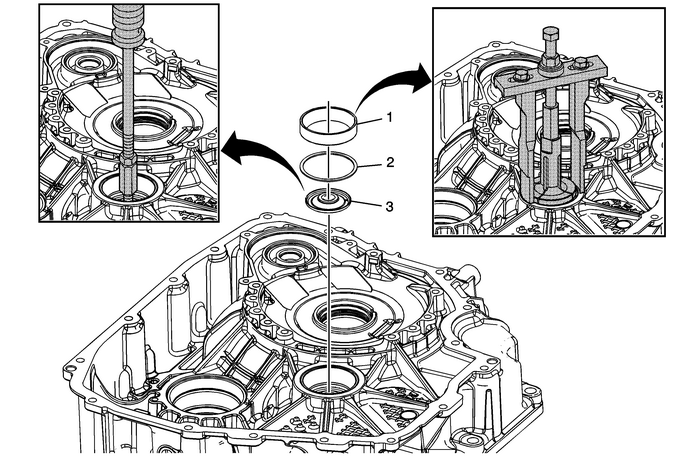

| Table 1: | Bearing Cup, Washer and Lubricant Dam Removal |

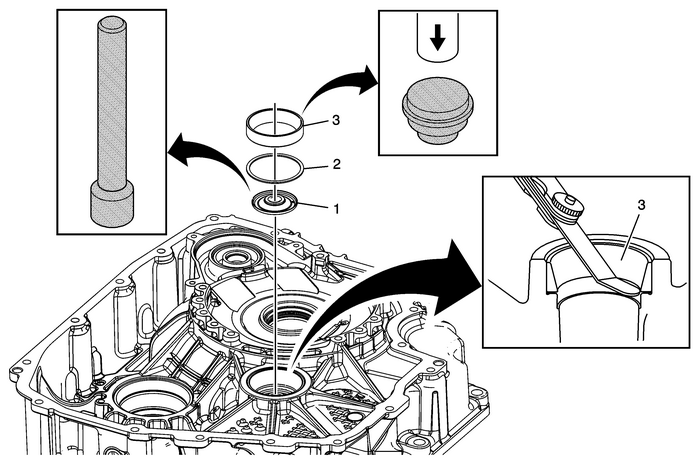

| Table 2: | Bearing Cup, Washer and Lubricant Dam Installation |

Preliminary Procedure Do not install the bearing cup until after the selective washer measurement has beenperformed. | |

1 | Front Differential Drive Pinion Gear Bearing Cup Caution:Failure to apply the lubricant will cause damage to the boltand nut threads. ProcedureTighten DT-45094 bearing cup remover until it fits snugly on the bearing cup.Adjust DT 45124 removal bridge so it sits on the torque converter housing surface just beyond the bearing cup opening.Apply the extreme pressure lubricant DT 23444-A extreme press lubricant to the puller bolt threads to prevent damage to the bolt threads during bearing cupremoval.Hold the puller bridge bolt and turn the nut to removal the bearing cup.Special ToolsDT 23444-A Extreme Press Lubricant-–-1/4 Ounce TubeDT-45087 Transfer Shaft and Differential Bearing Cup InstallerDT-45094 Bearing Cup RemoverDT 45124 Removal BridgeDT-47927 Bearing Cup RemoverFor equivalent regional tools, refer toSpecial Tools. |

2 | Front Differential Drive Pinion Gear Bearing Thrust Washer |

3 | Front Differential Drive Pinion Gear Lube Dam Special ToolsDT-48055 Lube Dam RemoverGE 6125-1B Slide Hammer with Adapter or equivalentFor equivalent regional tools, refer toSpecial Tools. |

Preliminary Procedure Do not install the bearing cup until after the selective washer measurement has beenperformed. | |

1 | Front Differential Drive Pinion Gear Lube Dam Special ToolsDT-46630 Lube Dam InstallerGE 8092 Driver HandleFor equivalent regional tools, refer toSpecial Tools. |

2 | Front Differential Drive Pinion Gear Bearing Thrust Washer Note:Install the correct drive pinion gear bearing thrust washer as determined by the thrustwasher measurement procedure. Refer toFront Differential Drive Pinion Gear Bearing Thrust Washer and Front DifferentialBearing Washer Measurement. |

3 | Front Differential Drive Pinion Gear Bearing Cup Caution:Support the back side of the torque converter housing beforeinstalling the bearing cup. Apply a light coating of transmissionfluid to the bore before pressing the cup into position. Installthe bearing cup until it stops moving. Applying excessive pressureto the bearing cup once it is seated could cause damage to thetorque converter housing casting. Caution:An unseated or improperly installed bearing cup will resultin premature bearing failure. Visually inspect the bearing cup toinsure there is“no gap” between the converterhousing, thrust washer, and the bearing cup. Use of a feeler gaugemay assist in identifying a bearing cup that is not fullyseated. Special Tools DT-45087 Bearing Cup Installer For equivalent regional tools, refer toSpecial Tools. |

Transmission Parts Kit Specifications Automatic Transmission Unit

Transmission Parts Kit Specifications Automatic Transmission Unit

Table 1: A/Trans Seal Kit (Gen 1& 2) 24251028Table 2: Front Wheel Seal Kit (Gen 1& 2) 19258415Table 3: Front Wheel Seal Kit (Gen 1& 2) 19258416Table 4: A/Trans Seal Kit (Gen 1) 24251353 (1 of 2)Table ...

Transmission Parts Kit Specifications Automatic Transmission Unit

Transmission Parts Kit Specifications Automatic Transmission Unit

Table 1: Clutch Plate Pack 24240100Table 2: Front Wheel Drive Shaft Seal Kit 19258265Table 3: Front Wheel Drive Shaft Seal Kit 19258266Table 4: Control Valve Body Kit 24248118Table 5: A/Trans Service ...

Other materials:

Rear Axle Vent Replacement Axles Rear

Rear Axle Vent ReplacementCalloutComponent NamePreliminary ProcedureRemove the rear differential assembly from the vehicle. RefertoDifferential Replacement.1Rear Differential VentProcedureRemove any dirt or debris from the vent area.Using an appropriate pair of pliers, remove the vent from therear d ...