Chevrolet Equinox Service Manual: Engine Prelubing

Note:This procedure is not used in Europe.

Special Tools

EN-45299 Engine Preluber

For equivalent regional tools, refer toSpecial Tools.

Note:A constant and continuous flow of clean engine oil is required in order to properlyprime the engine. Ensure an approved engine oil is used, as specified in the ownersmanual.

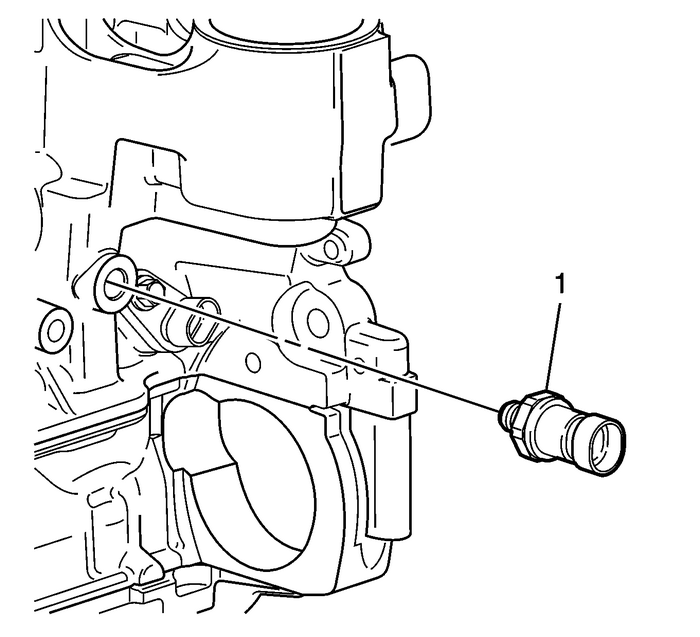

Remove the oil pressure switch.Install the M12-x-1.75 adapter-(1) P/N-509376.

Install the flexible hose to the adapter and open the valve.Pump the handle on the EN-45299 preluber-(1) in order to flow a minimum of 1–1.9-liters (1–2-quarts) of engine oil. Observethe flow of engine oil through the flexible hose and into the engine assembly.Close the valve and remove the flexible hose and adapter from the engine.

Caution:Refer toFastener Caution.

Install the oil pressure switch to the engine and tighten to 22-Y (16-lb-ft).Top-off the engine oil to the proper level. Piston, Connecting Rod, and Bearing Installation (LAF, LAT, LE5, LE9, LEA, or LUK) Engine Block Cylinder Block Piston Assembly

Piston, Connecting Rod, and Bearing Installation (LAF, LAT, LE5, LE9, LEA, or LUK) Engine Block Cylinder Block Piston Assembly

Note:This procedure is not used in Europe.Special ToolsEN-43966 Connecting Rod GuidesEN 45059 Angle MeterEN-47836 Piston Ring CompressorFor equivalent regional tools, refer toSpecial Tools.Install the ...

Exhaust System Description Exhaust

Exhaust System Description Exhaust

Note:Use of non-OEM parts may cause driveability concerns.The exhaust system carries exhaust gases, treated by thecatalytic converter, through a resonator, if applicable and intothe exhaust muffler wh ...

Other materials:

Engine Replacement

Special ToolsJ-38185Hose Clamp PliersFor equivalent regional tools, refer toSpecial Tools.Removal ProcedureRelieve the fuel pressure. Refer toFuel Pressure Relief.Remove negative battery cable from engine block. Refer toBattery Negative Cable ReplacementDisconnect the negative battery cable. Refer t ...