Chevrolet Equinox Service Manual: Crankshaft Sprocket Installation Engine Block Cylinder Block Crankshaft Sprocket

Special Tools

EN-48589Crankshaft Rotation Socket

For equivalent regional tools, refer toSpecial Tools.

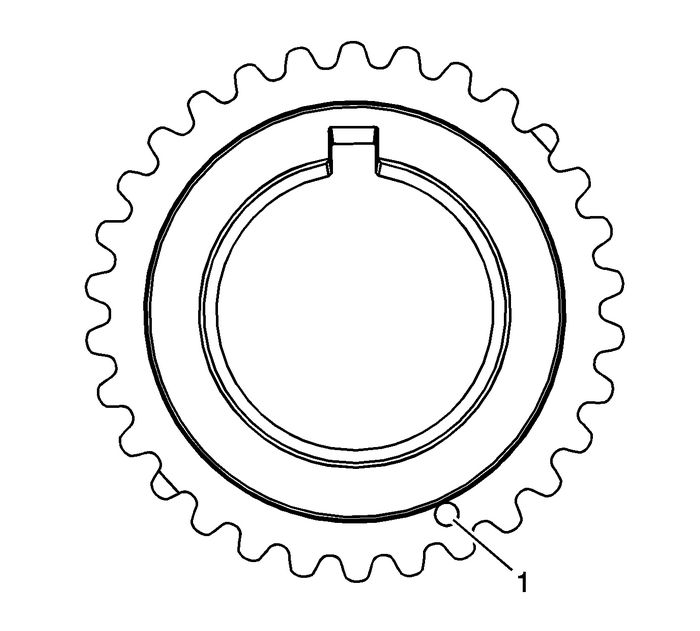

Ensure the crankshaft sprocket is installed with the timingmark-(1) visible.

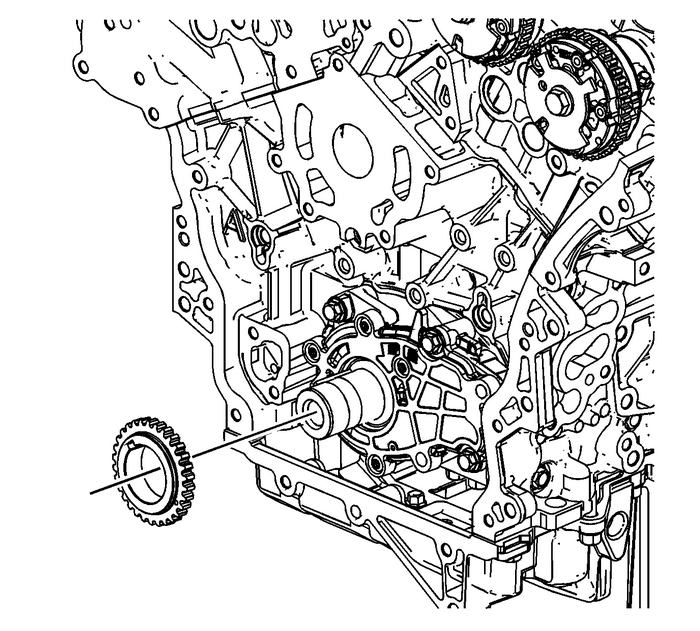

Install the crankshaft sprocket onto the nose of thecrankshaft.Align the notch in the crankshaft sprocket with the pin inthe crankshaft.Slide the crankshaft sprocket on the crankshaft nose untilthe crankshaft sprocket contacts the step in the crankshaft.

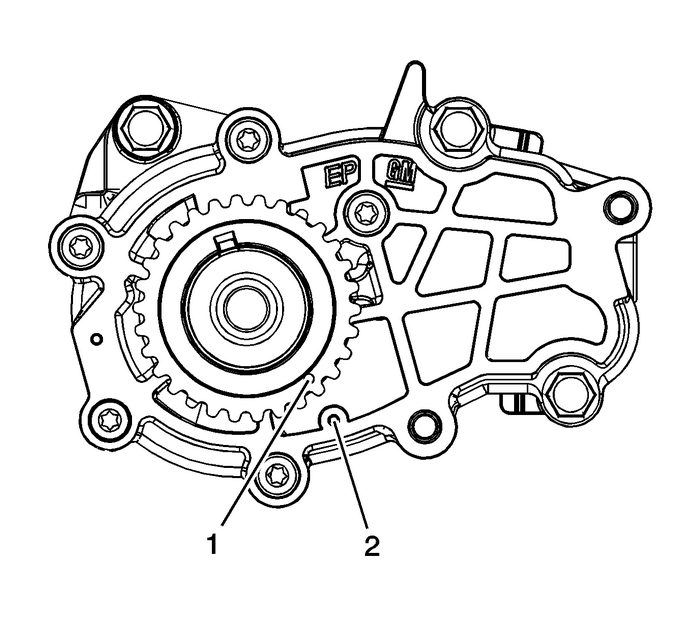

Ensure the crankshaft is in the stage one timing positionwith the crankshaft sprocket timing mark-(1) aligned tothe stage one timing mark on the oil pump cover-(2)using theEN-48589socket. Refer toTiming Chain Alignment Diagram.

Crankshaft Balancer Installation Engine Block Cylinder Block Crankshaft

Crankshaft Balancer Installation Engine Block Cylinder Block Crankshaft

Special ToolsEN-48585 Crankshaft Balancer GuideEN-48953 Camshaft Actuator Locking ToolEN 38122-A Crankshaft Balancer HolderEN 43653 Flywheel Holding ToolEN 45059 Angle MeterFor equivalent regional too ...

Intake Manifold Installation Intake and Forced Induction Intake Manifold

Intake Manifold Installation Intake and Forced Induction Intake Manifold

Special Tools EN-48896 HP Fuel Pump Installation Alignment GaugeFor equivalent regional tools, refer toSpecial Tools.Caution:Refer toFastener Caution.Install the intake manifold studs in the manifold ...

Other materials:

Intake Manifold Cleaning and Inspection Intake and Forced Induction Intake Manifold

Intake Manifold Cleaning ProcedureRemove any remaining gasket and/or gasket material from thefollowing:Throttle bodyIntake manifoldClean the following intake manifold areas in solvent.Intake manifold gasket sealing areasIntake manifold passagesBrake booster hose passageEvaporative emission (EVAP) so ...