Chevrolet Equinox Service Manual: Crankshaft Balancer Installation Engine Block Cylinder Block Crankshaft

Special ToolsEN-48585 Crankshaft Balancer GuideEN-48953 Camshaft Actuator Locking ToolEN 38122-A Crankshaft Balancer HolderEN 43653 Flywheel Holding ToolEN 45059 Angle Meter

For equivalent regional tools, refer toSpecial Tools.

Caution:Ensure both components are aligned correctly or seriousengine damage will occur.

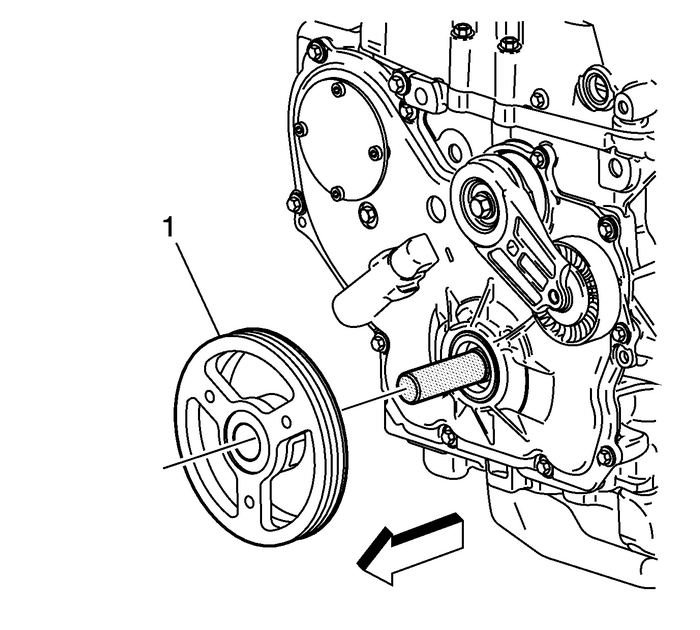

Install the EN 38122-A holder into the end of the crankshaft.Install the balancer-(1) onto the EN-48585 guide. Use care to properly align the keyway and flats on the balancer with the oil pumpdrive.

Note:EN 43653 locking tool may be used instead of EN 38122-A holder to prevent crankshaft rotation.

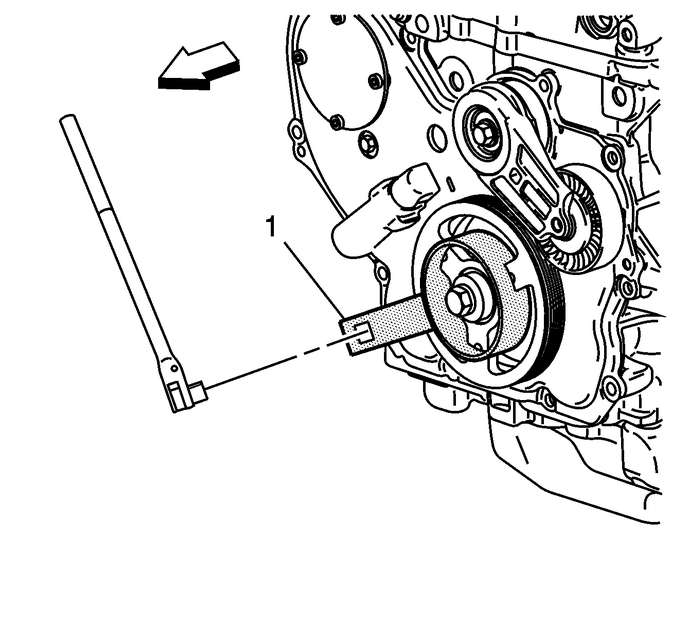

Install the EN 38122-A holder-(1).Caution:Refer toFastener Caution.

Note:Always install a new crankshaft balancer retaining bolt and washer.

Install a new retaining bolt and washer. Use the EN 38122-A holder and a breaker bar to prevent the crankshaft from rotating when tightening the bolt.Tighten the bolt to 150-Y (111-lb-ft) plus 100-degrees using the EN 45059 meter.

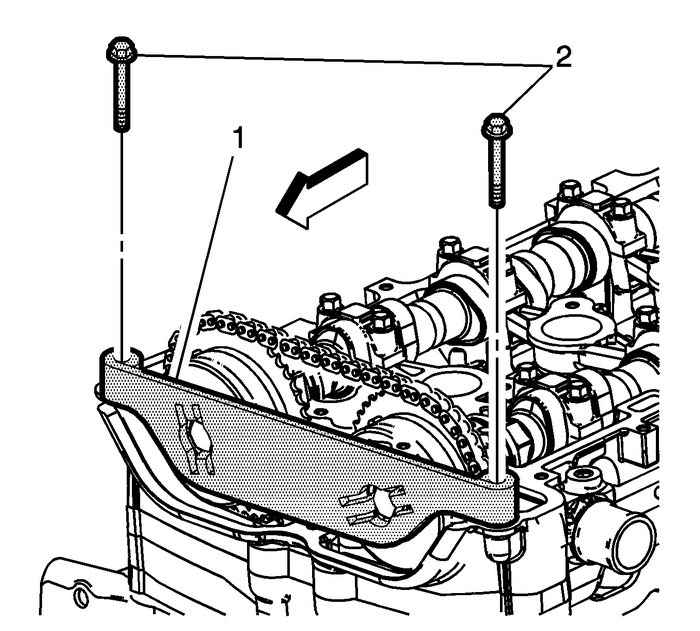

Install the EN-48953 locking tool-(1) and tighten the bolts into the cylinder head. Tighten the EN-48953 locking tool retaining bolts to 10-Y (89-lb-in).Release the timing chain tensioner by applying 45-Y (33-lb-ft) counterclockwise torque to the crankshaft balancer bolt.Remove the EN-48953 locking tool.

Secondary Camshaft Intermediate Drive Chain Installation - Left Side Valvetrain Camshaft

Secondary Camshaft Intermediate Drive Chain Installation - Left Side Valvetrain Camshaft

Special ToolsEN 48383Camshaft Retaining ToolsEN 48589Crankshaft Rotation SocketFor equivalent regional tools, refer toSpecial Tools.Note:There should be no need to rotate the camshaft more than10-degr ...

Crankshaft Sprocket Installation Engine Block Cylinder Block Crankshaft Sprocket

Crankshaft Sprocket Installation Engine Block Cylinder Block Crankshaft Sprocket

Special ToolsEN-48589Crankshaft Rotation SocketFor equivalent regional tools, refer toSpecial Tools.Ensure the crankshaft sprocket is installed with the timingmark-(1) visible.Install the crankshaft s ...

Other materials:

Front Wheel Drive Shaft Seal Removal - Torque Converter Housing Side Automatic Transmission Unit

Front Wheel Drive Shaft Seal Removal - Torque Converter Housing SideCalloutComponent Name1Front Wheel Drive Shaft Oil Seal AssemblySpecial ToolsDT-23129 Universal Seal RemoverGE-6125-B Slide HammerFor equivalent regional tools, refer toSpecial Tools. ...