Chevrolet Equinox Service Manual: Air Conditioning System Seal Replacement

Removal Procedure

Remove the seal washer from the A/C refrigerantcomponent.Inspect the seal washer for any signs of damage.Inspect the A/C refrigerant components for damage or burrs.Repair or replace as necessary.

Note:DO NOT reuse sealing washer.

Discard the sealing washer.Installation ProcedureNote:Flat washer type seals do not require lubrication.

Inspect the new seal washer for any signs of cracks, cuts, ordamage.Do not use a damaged seal washer.

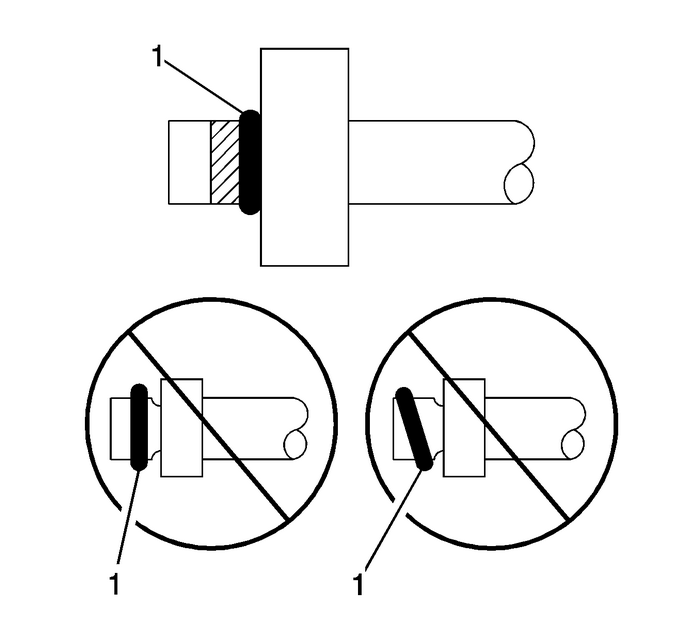

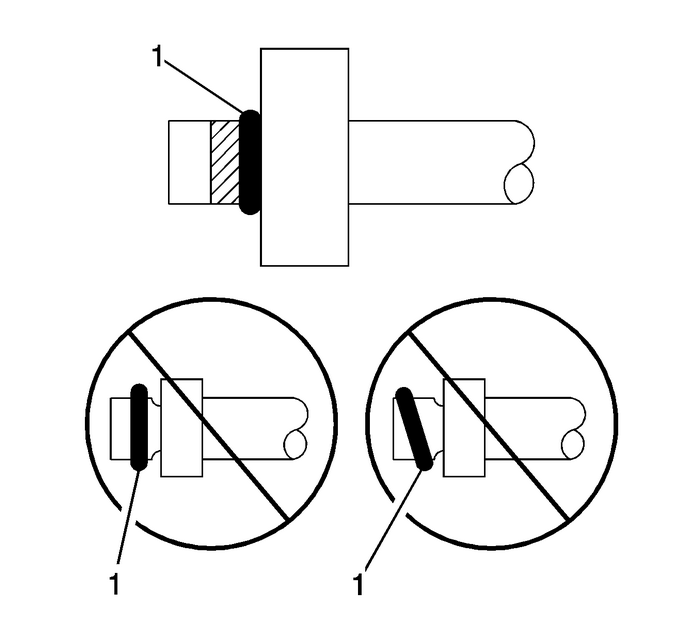

Using a lint-free clean, dry cloth, clean the sealingsurfaces of the A/C refrigerant components.Carefully install the new seal washer onto the A/Crefrigerant component.The washer must completely bottom against the surface of thefitting.

Note:After tightening the A/C components, there should be a slightsealing washer gap of approximately 1.2-mm(3/64-in) between the A/C line and the A/Ccomponent.

Assemble the remaining A/C refrigerant components. Refer tothe appropriate repair procedure. Air Conditioning (A/C) Evaporator Case Assembly Replacement Evaporator

Air Conditioning (A/C) Evaporator Case Assembly Replacement Evaporator

Removal ProcedureRemove the HVAC module. Refer toHeater and Air Conditioning Evaporator and Blower Module Removal and Installation.Remove the heater core cover screws from the evaporator caseassembly. ...

Side Window Defogger Outlet Duct Replacement - Left Side

Side Window Defogger Outlet Duct Replacement - Left Side

Side Window Defogger Outlet Duct Replacement - Left SideCalloutComponent NamePreliminary ProcedureRemove the instrument panel lower trim panel retainer. RefertoLower Trim Pad Retainer Replacement.1Sid ...

Other materials:

Towing Equipment

HitchesUse the correct hitch equipment. See your dealer or a hitch dealer for assistance.The rear bumper on the vehicle is not intended for hitches. Do not attach rental hitchesor other bumper-type hitches to it. Use only a frame-mounted hitch that does not attachto the bumper.Will any holes be made ...