Chevrolet Equinox Service Manual: Transmission Fluid Pump Disassemble (6T40/45/50) Automatic Transmission Unit

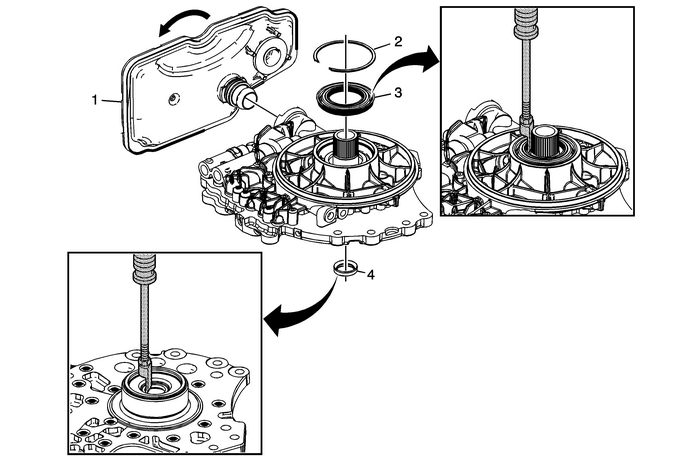

| Table 1: | Fluid Filter Assembly and Torque Converter Fluid Seal Disassemble |

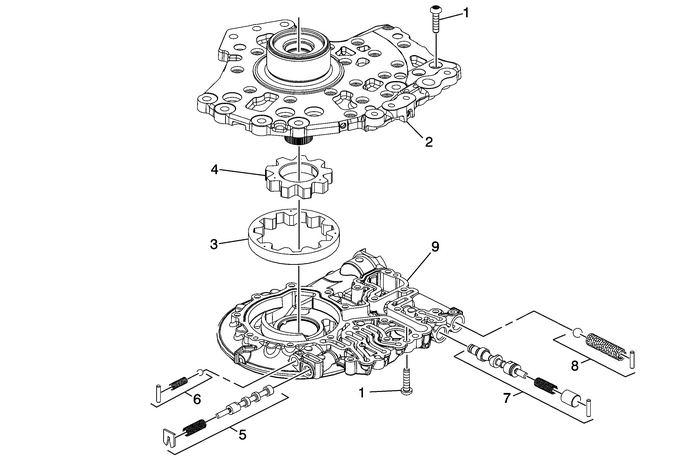

| Table 2: | Fluid Pump Disassemble |

1 | Fluid Filter Assembly Note:Rotate filter 90-degrees to disengage locking tangs. |

2 | Torque Converter Fluid Seal Retainer |

3 | Torque Converter Fluid Seal Special ToolsDT-23129 Universal Seal RemoverGE-6125-1B Slide HammerFor equivalent regional tools, refer toSpecial Tools. |

4 | Torque Converter Fluid Seal Assembly Special ToolsDT-23129 Universal Seal RemoverGE-6125-1B Slide HammerFor equivalent regional tools, refer toSpecial Tools. |

Warning:Valve springs can be tightly compressed. Use care whenremoving retainers and plugs. Personal injury could result. Caution:After cleaning the transmission components, allow to air dry.Do not use cloth or paper towels in order to dry any transmissioncomponents. Lint from the towels can cause componentfailure. Caution:Do not reuse cleaning solvents. Previously used solvents maydeposit sediment which may damage the component. Preliminary Procedure Clean and inspect all valve components and the pump body for wear and/or damage. | |

1 | Fluid Pump Cover Bolts-M6-x-25-(Qty:-23) Note:There are 3 bolts on the pump cover side and 20 bolts on the pump body side. |

2 | Fluid Pump Cover |

3 | Fluid Pump Driven Gear |

4 | Fluid Pump Drive Gear |

5 | TCC Control Valve Train |

6 | TCC Blow Off Ball Valve Train |

7 | Pressure Regulator Valve Train |

8 | Fluid Pump Blow Off Ball Valve Train |

9 | A/Trans Fluid Pump Body |

Front Differential Transfer Drive Gear Support Assembly Assemble Automatic Transmission Unit

Front Differential Transfer Drive Gear Support Assembly Assemble Automatic Transmission Unit

Table 1: Drive Support Seal InstallationTable 2: Fluid Passage Tube InstallationTable 3: Seal InstallationDrive Support Seal InstallationDrive Support Seal InstallationCalloutComponent Name1Front Diff ...

Transmission Fluid Pump Assemble (6T40/45/50) Automatic Transmission Unit

Transmission Fluid Pump Assemble (6T40/45/50) Automatic Transmission Unit

Table 1: Fluid Pump w/Valve Trains AssembleTable 2: Torque Converter Fluid Seal and Fluid Filter Assembly AssembleFluid Pump w/Valve Trains AssembleFluid Pump w/Valve Trains AssembleCalloutComponent N ...

Other materials:

Propeller Shaft Phasing Correction Driveshafts Propeller Shaft Assembly

One Piece Propeller Shaft Phasing CorrectionAn out of phase single-piece propeller shaft is very unusual.If the phasing inspection procedure revealed that prop shaft is notphased correctly, the welded yokes are in the wrong position, orthe shaft is damaged due to twisting and the propeller shaftrequ ...