Chevrolet Equinox Service Manual: Tire Pressure Indicator Sensor Replacement TPMS

Removal ProcedureRaise the vehicle on a suitable support. Refer toLifting and Jacking the Vehicle.Remove the tire/wheel assembly from the vehicle. Refer toTire and Wheel Removal and Installation.

Note:Before the tire is removed from the wheel, note the followingitems to avoid tire pressure sensor damage upon tiredismounting.

Place the sensor's cap and valve on a dry clean surface afterremoval. The cap is aluminum and the valve is nickel plated toprevent corrosion and are not to be substituted with a cap or valvemade of any other material.When separating the tire bead from the wheel, position thebead breaking fixture 90-degrees from the valvestem.Position the mounting/dismounting head so the tire iron, orpry bar can be inserted slightly clockwise of the sensor body whenprying the tire bead up and over the mounting/dismountinghead.Using the tire machine, rotate the tire/wheel assemblyclockwise when transferring the tire bead to the out side of thewheel rim.Repeat items for inner bead.Remove the tire from the wheel. Refer toTire Dismounting and Mounting.

Note:If any tire sealant is noted upon tire dismounting, removeall residual liquid sealant from the inside of the tire and wheelsurfaces.

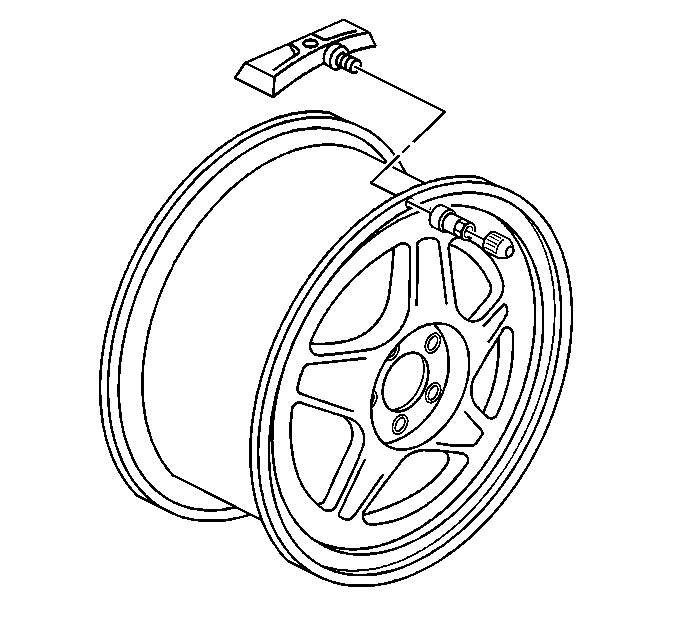

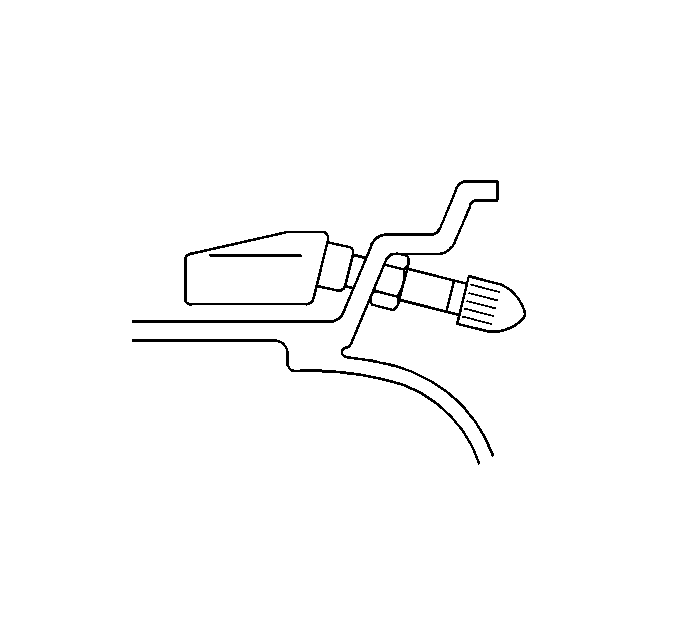

Remove the tire pressure sensor nut.Remove the tire pressure sensor.Installation ProcedureClean any dirt or debris from the grommet sealingarea.

Insert the sensor in the wheel hole with the air passagefacing away from the wheel.

Caution:Refer toFastener Caution.

Install the sensor nut and position the sensor body parallelto the inside wheel surface while torquing.Tighten the sensor nut to7-Y (62-lbin).

Note:Before reinstalling the tire on the wheel, note the followingitems to avoid tire pressure sensor damage upon tiremounting:

Position the mounting/dismounting head 180-degreesfrom the valve stem.Position the bead transition area 45-degreescounterclockwise of the valve stem.Using the tire machine, rotate the tire/wheel assemblyclockwise when transferring the tire bead to the inside of thewheel rim.Repeat items for outer bead.Install the tire on the wheel. Refer toTire Dismounting and Mounting.Note:A service replacement tire pressure sensor is shipped in OFFmode. In this mode the sensor's unique identification code cannotbe learned into the liftgate module (LGM) memory. The sensor mustbe taken out of OFF mode by spinning the tire/wheel assembly above32-km/h (20-mph) in order to close thesensor's internal roll switch for at least10-seconds.

Install the tire/wheel assembly on the vehicle. Refer toTire and Wheel Removal and Installation.Lower the vehicle.Learn the tire pressure sensors. Refer toTire Pressure Indicator Sensor Learn. Tire and Wheel Removal and Installation Wheels

Tire and Wheel Removal and Installation Wheels

Removal ProcedureRaise and support the vehicle. Refer toLifting and Jacking the Vehicle.If rotating the tires, refer toTire Rotation.Remove the wheel center cap, if equipped.Remove the wheel center ca ...

Wheel Replacement Wheels

Wheel Replacement Wheels

Replace any wheel that is bent, cracked, or badly rusted or corroded. If wheel nutskeep coming loose, the wheel, wheel bolts, and wheel nuts should be replaced. If thewheel leaks air, replace it. Some ...

Other materials:

#99-04-20-002H: Information on Driveline Clunk Noise - (Apr 11, 2013)

Subject:Information on Driveline Clunk NoiseModels: 2014 and Prior GM Passenger Cars and Light Duty Trucks This bulletin is being revised to add the 2013-2014 model years. Please discard CorporateBulletin Number-99-04-20-002G (Section 04 – Driveline/Axle).Important:The condition described in ...