Chevrolet Equinox Service Manual: Rocker Inner Panel Reinforcement Replacement

Removal Procedure

Warning:Refer toApproved Equipment for Collision Repair Warning.

Warning:Refer toGlass and Sheet Metal Handling Warning.

Disable the SIR system. Refer toSIR Disabling and Enabling.Disconnect the negative battery cable. Refer toBattery Negative Cable Disconnection and Connection.Remove all related panels and components.Perform additional procedures as necessary. Refer toFront Hinge Pillar Body Sectioning.Restore as much of the damage as possible to factoryspecifications using 3-dimensional measuring equipment.

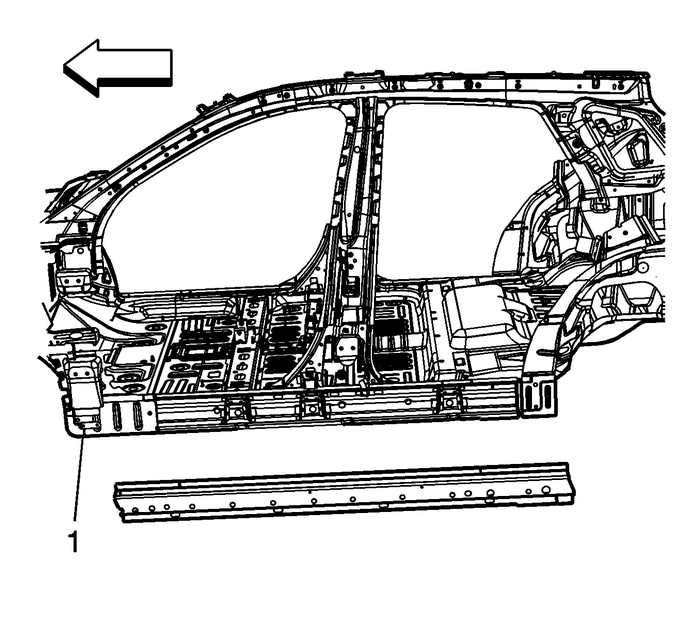

Note the location and remove the sealers and anti-corrosionmaterials from the repair area, as necessary-(1). RefertoAnti-Corrosion Treatment and Repair.

Note:Do not damage any inner panels or reinforcements.

Note:The rocker inner panel is made of ultra high strength steeland should be replaced only at factory joints. Sectioning orstraightening are not recommended. Refer toUltra High Strength Steel.

Note:Ultra high steel is very difficult to drill. When possibledrill spot welds from the back side of the panel.

Note:Record the number and location of the original welds forinstallation of the service part.

Locate and drill out all factory welds-(1).

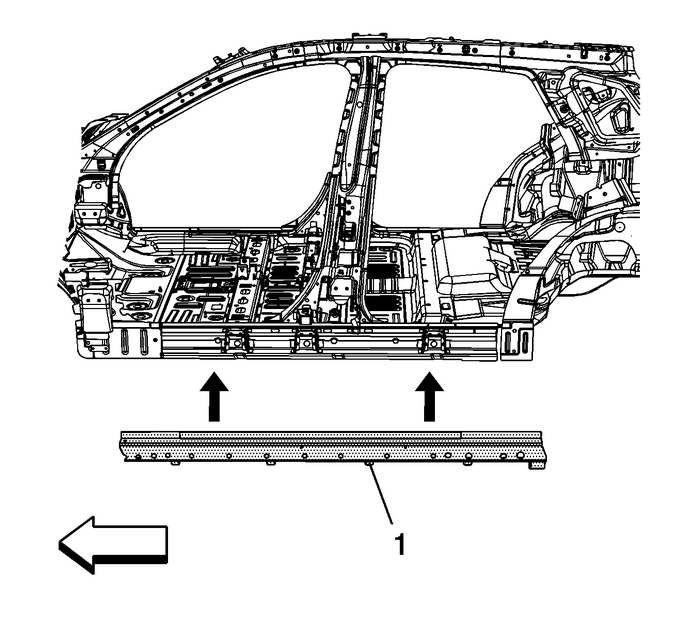

Remove the damaged inner rocker panel-(1).Installation Procedure

Note:If the location of the original plug welds cannot bedetermined or structural weld thru adhesive was present, space plugweld holes every 40-mm (1-1/2-in)apart.

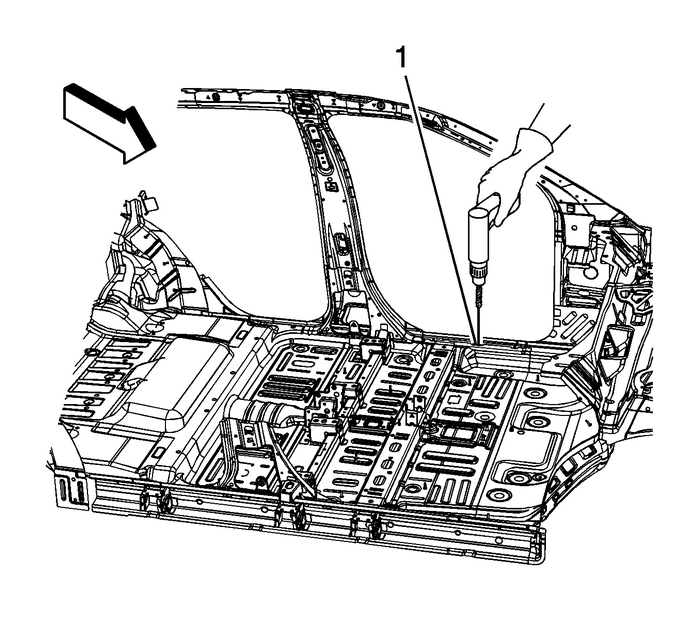

Drill 8 mm (5/16-in) plug weld holes in theservice part as necessary-(1), in the locations notedfrom the original panel.Prepare all attachment surfaces as necessary.Apply GM approved Weld-Thru Coating or equivalent to allmating surfaces. Refer toAnti-Corrosion Treatment and Repair.

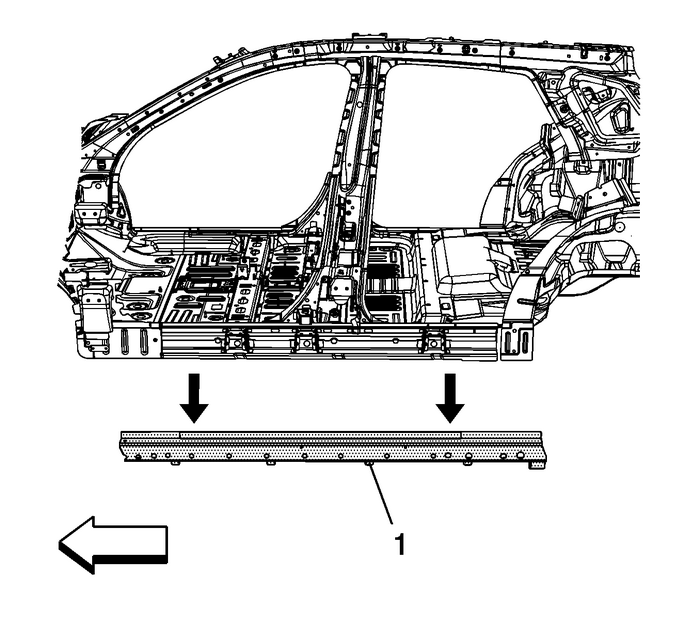

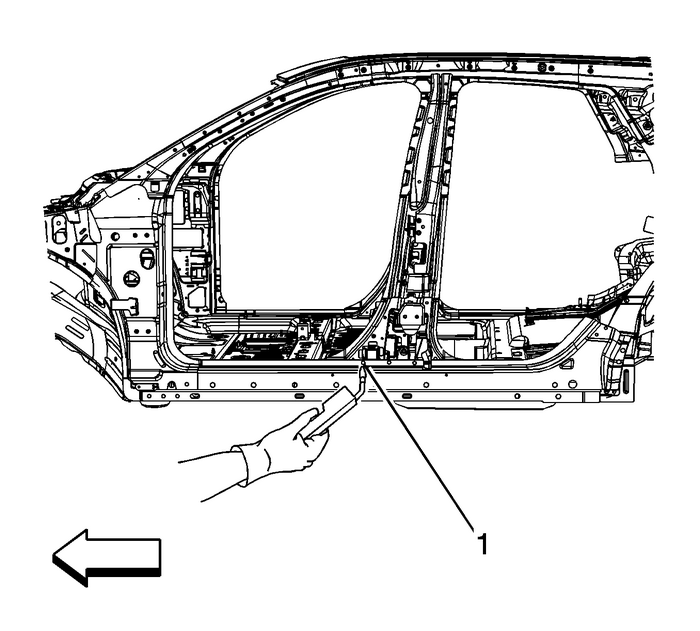

Position the inner rocker panel-(1).Clamp service parts in position.Inspect the vehicle for proper dimensions using 3-dimensionalequipment.

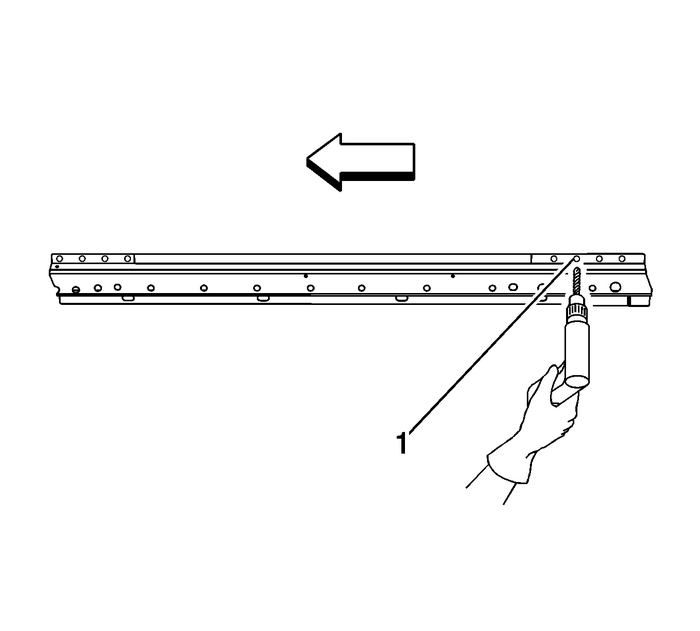

Plug weld accordingly-(1).Clean and prepare all welded surfaces.Apply the sealers and anti-corrosion materials to the repairarea, as necessary. Refer toAnti-Corrosion Treatment and Repair.Paint the repair area. Refer toBasecoat/Clearcoat Paint Systems.Install all related panels and components.Connect the negative battery cable. Refer toBattery Negative Cable Disconnection and Connection.Enable the SIR system. Refer toSIR Disabling and Enabling.

Rail Replacement - Rear Section

Rail Replacement - Rear Section

Removal ProcedureWarning:Refer toApproved Equipment for Collision Repair Warning.Disable the supplemental inflatable restraint (SIR) system.Refer toSIR Disabling and Enabling.Disconnect the negative b ...

Body Rear End Panel Replacement

Body Rear End Panel Replacement

Removal ProcedureWarning:Refer toApproved Equipment for Collision Repair Warning.Warning:Refer toGlass and Sheet Metal Handling Warning.Disable the supplemental inflatable restraint (SIR) system.Refer ...

Other materials:

General Information

Your vehicle is an important

investment. This section describes

the required maintenance for the

vehicle. Follow this schedule to help

protect against major repair

expenses resulting from neglect or

inadequate maintenance. It may

also help to maintain the value of

the vehicle if it is sold. ...