Chevrolet Equinox Service Manual: Piston, Connecting Rod, and Bearing Replacement Engine Block Cylinder Block Piston Assembly

Special ToolsEN-8037Ring CompressorEN-24270Cylinder Bore Ridge ReamerEN-43966-1Connecting Rod GuidesEN-45059Angle Meter

For equivalent regional tools, refer toSpecial Tools.

Removal ProcedureRemove the oil pan. Refer toOil Pan Replacement.Remove the cylinder head. Refer toCylinder Head Replacement.

If a ring ridge is present, remove the ring ridge asfollows:Turn the crankshaft until the piston is at the bottom of thestroke.Place a cloth on top of the piston.Use aEN-24270reamerto remove the ring ridge.Turn the crankshaft so the piston is at top of thestroke.Remove the cloth and cutting debris.

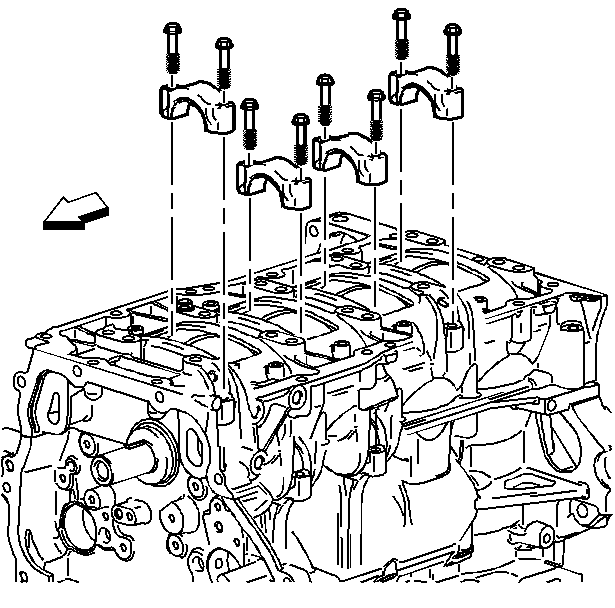

Note:Place the numbers on connecting rods and the connecting rodcaps. The connecting rod caps must be assembled to their originalconnecting rods.

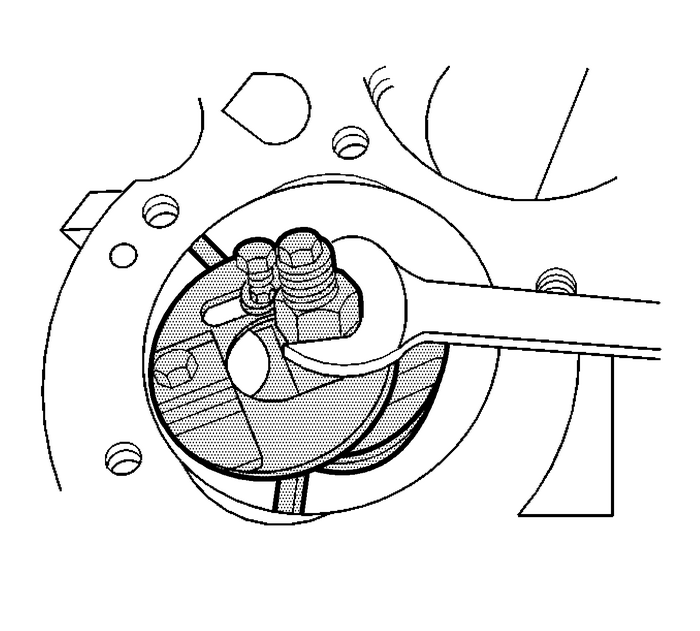

Remove the connecting rod nuts and the connecting rodcap.Discard the bolts and nuts.

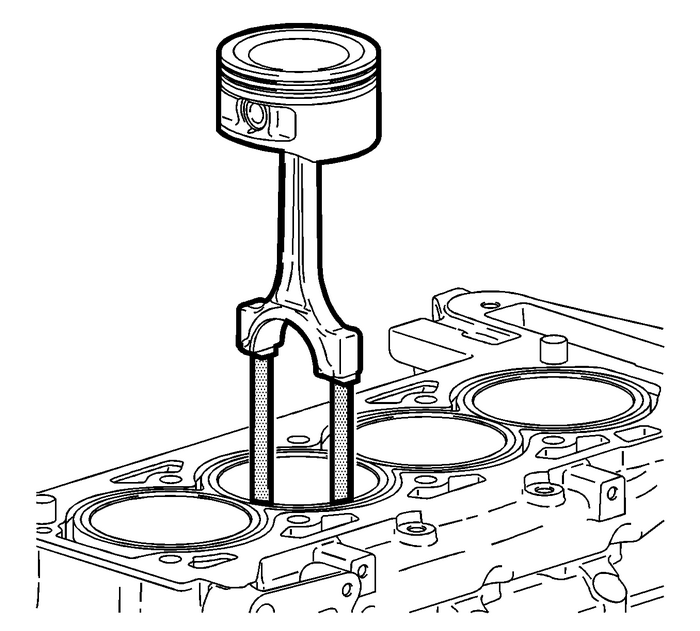

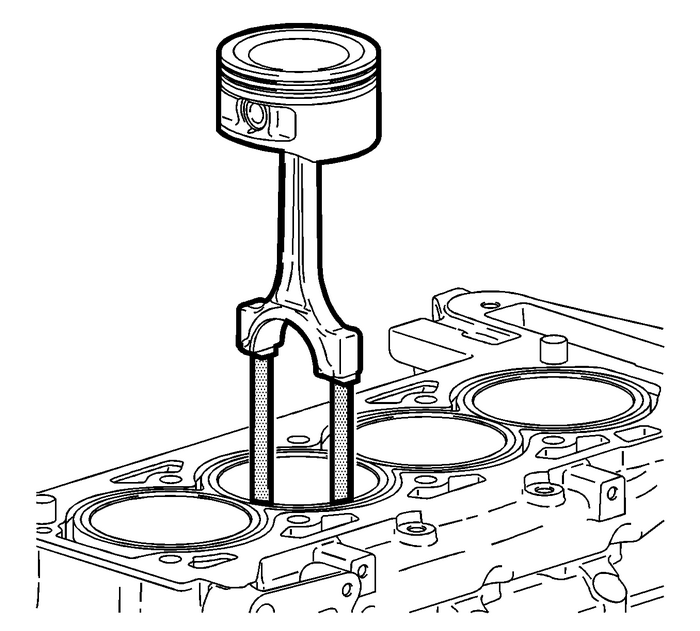

Remove the connecting rod and the piston out of the top ofthe engine block using theEN-43966-1guides.Clean the cylinder bores with hot water and detergent or witha light honing.Swab the bores with the engine oil and a clean, drycloth.Installation ProcedureCoat the following parts with engine oil:The pistonThe piston ringsThe cylinder boreThe bearing surfaces

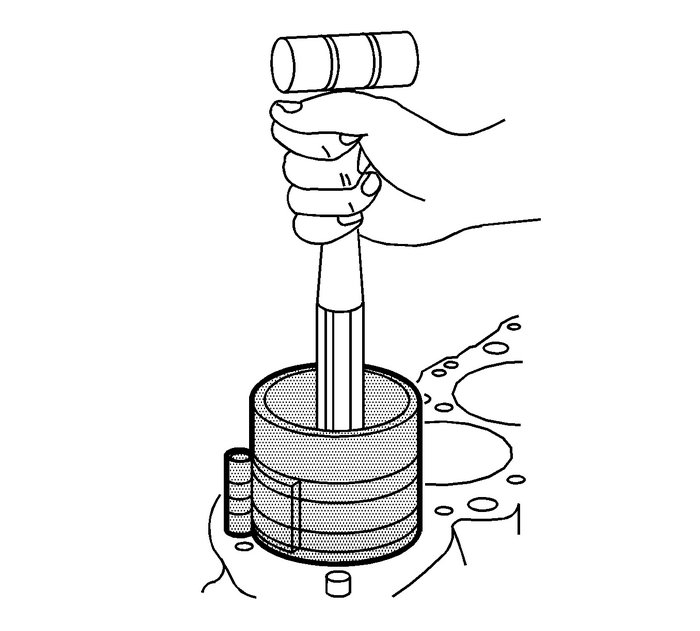

Install the piston into its original bore using theEN-43966-1guides.

Lightly tap the top of the piston with a wooden hammerhandle.When installing the piston and the connecting rod, thestamped mark on the piston must point to the front of theengine.Hold theEN-8037compressorfirmly against the engine block until all the piston ringshave entered the cylinder bore.Install the connecting rod caps onto their originalconnecting rods.Align the numbers placed on the connecting rod and theconnecting rod cap during removal.

Caution:Refer toFastener Caution.

Install the new connecting rod bolts and nuts.On the first pass, tighten the nuts evenly to25-Y(18-lb-ft).On the final pass, use theEN-45059meterin order to tighten the nutsan additional100-degrees.

Measure the connecting rod side clearance with a feelergauge.

The correct clearance is 0.070–0.370-mm(0.0027–0.0145-in).

Install the cylinder head. Refer toCylinder Head Replacement.Install the oil pan. Refer toOil Pan Replacement. Camshaft Position Actuator Replacement - Bank 1 Valvetrain Camshaft

Camshaft Position Actuator Replacement - Bank 1 Valvetrain Camshaft

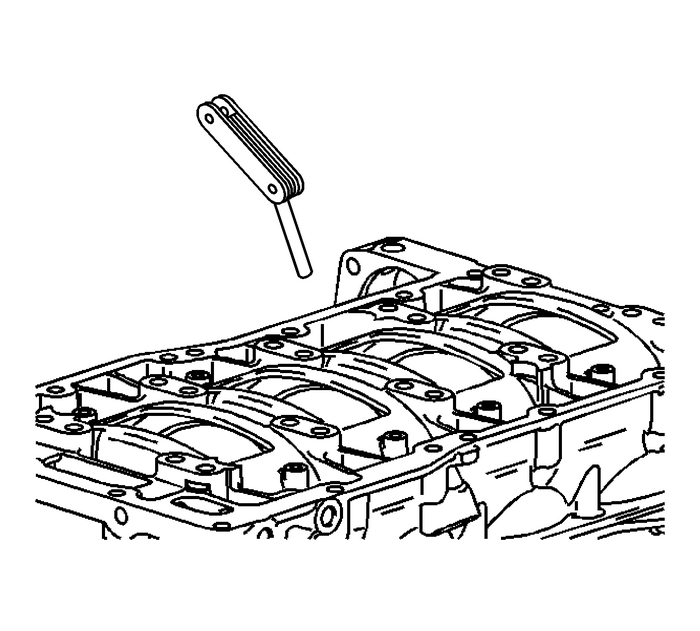

Special ToolsEN49982-1 Timing Chain RetainerEN49982-2 Timing Chain RetainerFor equivalent regional tools, refer toSpecial Tools.Removal ProcedureRemove the camshaft cover. Refer toCamshaft Cover Repla ...

Piston, Connecting Rod, and Bearing Installation Engine Block Cylinder Block Piston Assembly

Piston, Connecting Rod, and Bearing Installation Engine Block Cylinder Block Piston Assembly

Special ToolsEN 8037 Ring CompressorEN 43690-A Rod Bearing Clearance Checking ToolEN 45059 Angle MeterEN 46121 Connecting Rod Guide Pin SetEN 48589 Crankshaft Rotation SocketFor equivalent regional to ...

Other materials:

Battery Positive Cable Replacement (LEA) Low Voltage Battery

Removal ProcedureRecord all of the radio station presets.Disconnect the battery negative cable. Refer toBattery Negative Cable Disconnection and Connection.Remove the battery positive post clampnut-(2).Remove battery positive terminal-(1) at the fuseblock.Disconnect retainers-(3) holding battery pos ...