Chevrolet Equinox Service Manual: Oil Pan Cleaning and Inspection Engine Lubrication Oil Sump/Pan

Special Tools

EN 28410 Gasket Remover

For equivalent regional tools, refer toSpecial Tools

Cleaning ProcedureRemove any old thread sealant, gasket material or sealant using EN 28410 remover.Clean the oil pan and oil pan components in solvent.Clean out debris from the bolt holes.Warning:Refer toSafety Glasses Warning.

Dry the oil pan and oil pan components with compressed air.Inspection Procedure

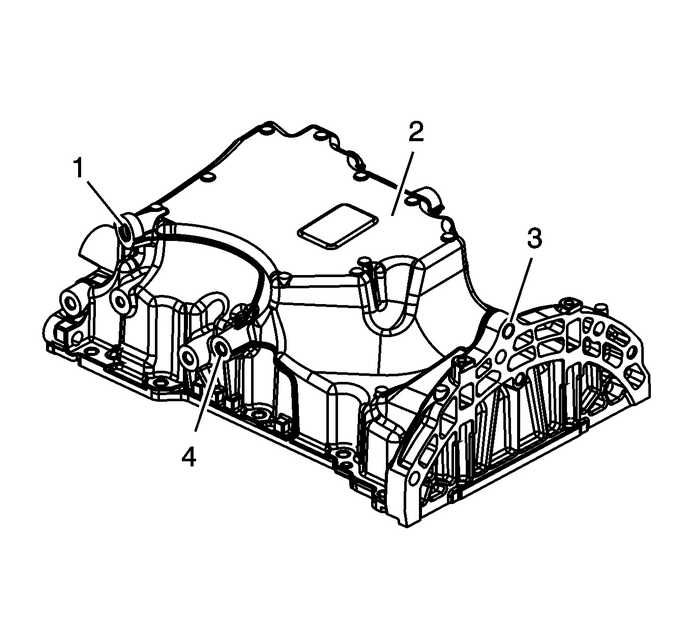

Inspect the exterior of the oil pan for the following conditions:Dents or damage to the exterior-(2)Damage to the drain plug or drain plug hole-(1)Damage to the brace mounting bosses-(4)Damage to the mounting bosses-(3)

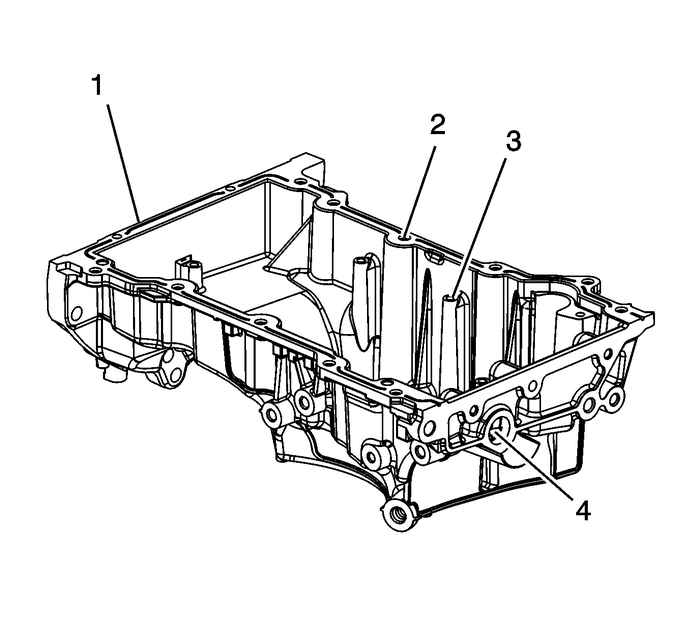

Inspect the interior of the oil pan for the following conditions:Gouges or damage to the oil pan sealing surfaces-(1)Damage to the oil pan scraper mounting holes-(2)Damage to the bolt holes-(3)Damage to the engine oil level switch hole-(4)Repair or replace the oil pan and/or oil pan components as necessary.

Crankcase Ventilation System Inspection/Diagnosis (Without Turbocharger) Emissions PCV

Crankcase Ventilation System Inspection/Diagnosis (Without Turbocharger) Emissions PCV

Special ToolsEN 23951Valve ManometerRemove the oil level indicator. Install aEN 23951valve manometeror equivalent.Start the engine.Check for slight vacuum. The vacuum level should be less than3.377-kP ...

Engine Front Cover Cleaning and Inspection Engine Block Cylinder Block Cyl Block Front Cover

Engine Front Cover Cleaning and Inspection Engine Block Cylinder Block Cyl Block Front Cover

Special ToolsEN 28410Gasket RemoverFor equivalent regional tools, refer toSpecial Tools.Cleaning ProcedureRemove any RTV sealant-(1) from the engine frontcover usingEN 28410remover.Clean out debris fr ...

Other materials:

#06-06-01-010B: Information on Close-Coupled Converter and Engine Replacement - (Aug 19, 2013)

Subject:Information on Close-Coupled Converter and Engine ReplacementModels: 2004-2014 GM Cars and Truckswith Close-Coupled Catalytic ConvertersThis bulletin has been revised to add the 2009-2014 model years. Please discard CorporateBulletin Number 06-06-01-010A.Certain 2004-2014 General Motors pro ...