Chevrolet Equinox Service Manual: Front Differential Carrier Cleaning and Inspection Automatic Transmission Unit

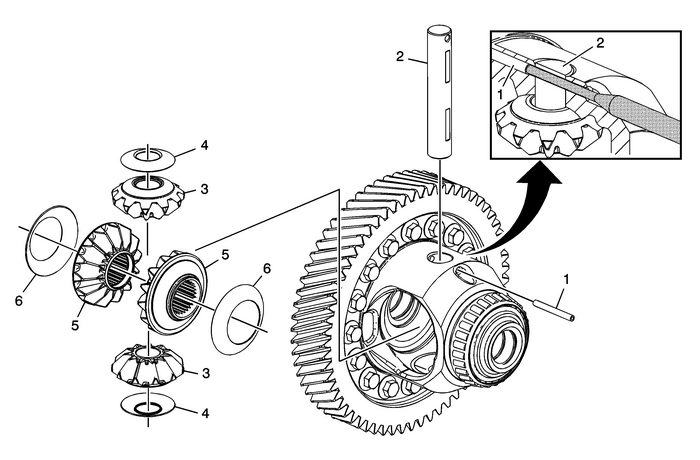

Caution:After cleaning the transmission components, allow to air dry.Do not use cloth or paper towels in order to dry any transmissioncomponents. Lint from the towels can cause componentfailure. Caution:Do not reuse cleaning solvents. Previously used solvents maydeposit sediment which may damage the component. Caution:Keep the thrust washers with gear it was matched to. Thethrust washers are selective sizes and it is difficult to identifythe proper washer thickness. Improper assembly can cause prematurefailure of the differential assembly. Preliminary Procedure Clean and inspect the differential assembly, pinion gears and thrust washers for scoring,wear or damage. The differential assembly is only serviced as an assembly. | |

1 | Front Differential Pinion Gear Shaft Retainer Note:Discard and use a new retainer. Special Tools 3/16-in-(5-mm) 7-in Punch or equivalent For equivalent regional tools, refer toSpecial Tools. |

2 | Front Differential Pinion Gear Shaft |

3 | Front Differential Pinion Gears |

4 | Front Differential Carrier Thrust Washers |

5 | Front Differential Pinion Side Gears |

6 | Front Differential Side Gear Thrust Washer |

Front Differential Carrier Bearing Installation (AWD) Automatic Transmission Unit

Front Differential Carrier Bearing Installation (AWD) Automatic Transmission Unit

Front Differential Carrier Bearing InstallationCalloutComponent Name1Front Differential Carrier BearingNote:Press the bearing until the tool stops against the housing to ensure the bearing isinstalled ...

Front Differential Carrier Final Rotational Torque Measurement Automatic Transmission Unit

Front Differential Carrier Final Rotational Torque Measurement Automatic Transmission Unit

Front Differential Carrier Final Rotational Torque MeasurementCalloutComponent Name1Front Differential Carrier AssemblyCaution:Low bearing pre-load will cause premature failureof the front differentia ...

Other materials:

Primary Timing Chain Guide Installation - Lower Valvetrain Valvetrain Timing Timing Belt/Chain

Position the primary camshaft drive chain lower guide to theoil pump.Caution:Refer toFastener Caution.Install the primary camshaft drive chain lower guide boltsand tighten to25-Y(18-lb-ft). ...