Chevrolet Equinox Service Manual: Fasteners

| Table 1: | Metric Prevailing Torque Fastener Minimum Torque Development |

| Table 2: | English Prevailing Torque Fastener Minimum Torque Development |

This vehicle provides fastener dimensions using the metric system. Most metric fastenersare approximate in diameter to equivalent English fasteners. Make replacements usingfasteners of the same nominal diameter, thread pitch, and strength.

A number marking identifies the OE metric fasteners except cross-recess head screws.The number also indicates the strength of the fastener material. A Posidrive® or Type-1Across-recess identifies a metric cross-recess screw. For best results, use a Type-1Across-recess screwdriver, or equivalent, in Posidrive® recess head screws.

GM Engineering Standards and North American Industries have adopted a portion of theISO-defined standard metric fastener sizes. The purpose was to reduce the number offastener sizes used while retaining the best thread qualities in each thread size.For example, the metric M6.0-X-1 screw, with nearly the same diameter and 25.4-threadsper inch replaced the English 1/4–20 and 1/4–28 screws. The thread pitch is midwaybetween the English coarse and fine thread pitches.

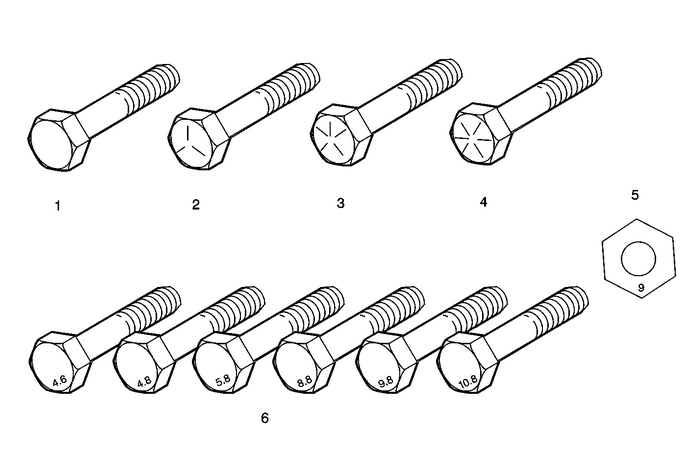

Fastener Strength Identification

| (1) | English Bolt, Grade-2(Strength Class) |

| (2) | English Bolt, Grade-5(Strength Class) |

| (3) | English Bolt, Grade-7(Strength Class) |

| (4) | English Bolt, Grade-8(Strength Class) |

| (5) | Metric Nut, StrengthClass-9 |

| (6) | Metric Bolts, Strength ClassIncreases as Numbers Increase |

The most commonly used metric fastener strength property classes are 9.8 and 10.9.The class identification is embossed on the head of each bolt. The English, inch strengthclasses range from grade-2 to grade-8. Radial lines are embossed on the head of eachbolt in order to identify the strength class. The number of lines on the head of thebolt is 2-lines less than the actual grade. For example, a grade-8bolt will have 6-radial lines on the bolt head. Some metric nuts are marked with asingle digit strength identification number on the nut face.

The correct fasteners are available through GM SPO. Many metric fasteners availablein the aftermarket parts channels are designed to metric standards of countries otherthan the United States, and may exhibit the following:

Lower strengthNo numbered head marking systemWrong thread pitchThe metric fasteners on GM products are designed to new, international standards.The following are the common sizes and pitches, except for special applications:

M6.0 X 1M8 X 1.25M10 X 1.5M12 X 1.75M14 X 2.00M16 X 2.00Prevailing Torque FastenersPrevailing torque fasteners create a thread interface between the fastener and thefastener counterpart in order to prevent the fastener from loosening.

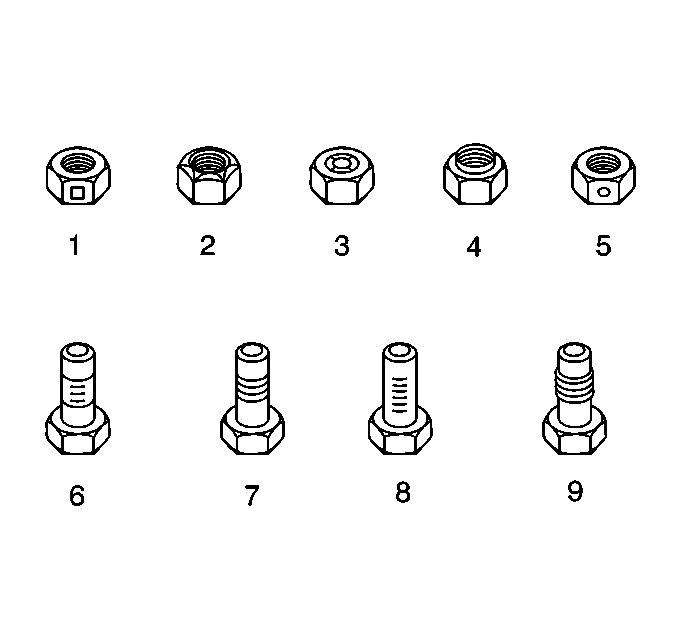

All Metal Prevailing Torque Fasteners

These fasteners accomplish the thread interface by a designed distortion or deformationin the fastener.

Nylon Interface Prevailing Torque Fasteners

These fasteners accomplish the thread interface by the presence of a nylon materialon the fastener threads.

Adhesive Coated Fasteners

These fasteners accomplish the thread interface by the presence of a thread-lockingcompound on the fastener threads. Refer to the appropriate repair procedure in orderto determine if the fastener may be reused and the applicable thread-locking compoundto apply to the fastener.

| (1) | Prevailing Torque Nut, Center LockType |

| (2) | Prevailing Torque Nut, Top LockType |

| (3) | Prevailing Torque Nut, Nylon PatchType |

| (4) | Prevailing Torque Nut, Nylon WasherInsert Type |

| (5) | Prevailing Torque Nut, Nylon InsertType |

| (6) | Prevailing Torque Bolt, Dry AdhesiveCoating Type |

| (7) | Prevailing Torque Bolt, ThreadProfile Deformed Type |

| (8) | Prevailing Torque Bolt, Nylon StripType |

| (9) | Prevailing Torque Bolt, Out-of-RoundThread Area Type |

A prevailing torque fastener may be reused ONLY if:

The fastener and the fastener counterpart are clean and not damagedThere is no rust on the fastenerThe fastener develops the specified minimum torque against its counterpart prior tothe fastener seatingAll Metal Prevailing Torque Fasteners | ||

| 6 mm | 0.4-Y | 4-lb-in |

| 8 mm | 0.8-Y | 7-lb-in |

| 10 mm | 1.4-Y | 12-lb-in |

| 12 mm | 2.1-Y | 19-lb-in |

| 14 mm | 3-Y | 27-lb-in |

| 16 mm | 4.2-Y | 37-lb-in |

| 20 mm | 7-Y | 62-lb-in |

| 24 mm | 10.5-Y | 93-lb-in |

Nylon Interface Prevailing Torque Fasteners | ||

| 6 mm | 0.3-Y | 3-lb-in |

| 8 mm | 0.6-Y | 5-lb-in |

| 10 mm | 1.1-Y | 10-lb-in |

| 12 mm | 1.5-Y | 13-lb-in |

| 14 mm | 2.3-Y | 20-lb-in |

| 16 mm | 3.4-Y | 30-lb-in |

| 20 mm | 5.5-Y | 49-lb-in |

| 24 mm | 8.5-Y | 75-lb-in |

All Metal Prevailing Torque Fasteners | ||

| 1/4 in | 0.5-Y | 4.5-lb-in |

| 5/16 in | 0.8-Y | 7.5-lb-in |

| 3/8 in | 1.3-Y | 11.5-lb-in |

| 7/16 in | 1.8-Y | 16-lb-in |

| 1/2 in | 2.3-Y | 20-lb-in |

| 9/16 in | 3.2-Y | 28-lb-in |

| 5/8 in | 4-Y | 36-lb-in |

| 3/4 in | 7-Y | 54-lb-in |

Nylon Interface Prevailing Torque Fasteners | ||

| 1/4 in | 0.3-Y | 3-lb-in |

| 5/16 in | 0.6-Y | 5-lb-in |

| 3/8 in | 1-Y | 9-lb-in |

| 7/16 in | 1.3-Y | 12-lb-in |

| 1/2 in | 1.8-Y | 16-lb-in |

| 9/16 in | 2.5-Y | 22-lb-in |

| 5/8 in | 3.4-Y | 30-lb-in |

| 3/4 in | 5-Y | 45-lb-in |

Front View Camera Module Scan Tool Information

Front View Camera Module Scan Tool Information

Table 1: Front View Camera Module Scan Tool Data ParametersTable 2: Front View Camera Module Scan Tool Output ControlsFront View Camera Module Scan Tool Data ParametersParameterSystem StateExpected Va ...

Definition of Danger, Warning, Caution, and Note

Definition of Danger, Warning, Caution, and Note

The diagnosis and repair procedures in a GM Service Manualcontain both general and specific Dangers, Warnings, Cautions,Notes or Importants. GM is dedicated to the presentation of serviceinformation t ...

Other materials:

Special Tools

IllustrationTool Number/DescriptionCH-25033-CJ-25033-CPulley InstallerCH-25034-CJ-25034-CPulley RemoverCH-45722J-45722Fuel Sender Lock Ring WrenchCH-48027DW 100-010EN 49495J-21867Digital Pressure GaugeSouth America Use Local EquivalentCH-48482Fuel Sender Lock Ring WrenchDT-5590J-5590J-24254Bearing a ...