Chevrolet Equinox Service Manual: Engine Prelubing

Note:This procedure is not used in Europe.

Special ToolsEN 21867-6 Oil Pressure Adapter FittingEN 45299 Engine PreluberFor equivalent regional tools, refer toSpecial Tools

Note:A constant and continuous flow of clean engine oil is required in order to properlyprime the engine. Be sure to use an approved engine oil as specified in the ownersmanual.

Remove the oil filter cap.Install the NEW oil filter cartridge.Lubricate the threads of the oil filter cap with clean engine oil.Caution:Refer toFastener Caution.

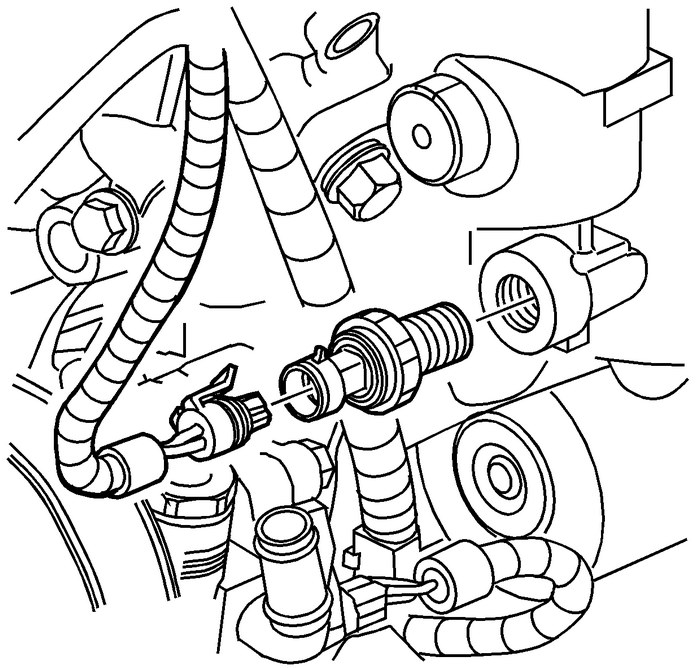

Install the oil filter cap and tighten to 25-Y (18-lb-ft).Remove the oil pressure sending unit from the oil filter adapter.Install the EN 21867-6 fitting.

Install the flexible hose to the adapter and open the valve.Pump the handle on the EN 45299 preluberin order to flow a minimum of 1–1.9-liters (1–2-quarts) of engine oil. Observe theflow of engine oil through the flexible hose and into the engine assembly.Close the valve and remove the flexible hose and adapter from the engine.Install the oil pressure sending unit and tighten to 20-Y (15-lb-ft).Top-off the engine oil to the proper level.

Oil Pan Installation Engine Lubrication Oil Sump/Pan

Oil Pan Installation Engine Lubrication Oil Sump/Pan

Note:The lower crankcase surface must be free of contaminationprior to applying the sealer.Install and align the oil pan to block within20-minutes of applying the sealer.The oil pan must be fastened t ...

Balance Shaft Removal Engine Block Cylinder Block Balance Shaft

Balance Shaft Removal Engine Block Cylinder Block Balance Shaft

Note:This procedure is not used in Europe.Special Tools EN-43650 Balancer Shaft Bearing Remover and InstallerFor equivalent regional tools, refer toSpecial Tools.Remove the balance shaft bearing carri ...

Other materials:

Steering Wheel Horn Contact Replacement Steering Wheel and Column

Steering Wheel Horn Contact ReplacementCalloutComponent NamePreliminary ProcedureRemove the inflatable restraint steering wheel module. RefertoAirbag Steering Wheel Module Replacement.1Steering Wheel Horn Contact Bolt/Screw(Qty:-3)Caution:Refer toFastener Caution.Tighten8-Y(71-lb-in)2Steering Wheel ...