Chevrolet Equinox Service Manual: Cylinder Head Installation - Left Side Engine Block Cylinder Head

Special Tools

EN 45059 Angle Meter

For equivalent regional tools, refer toSpecial Tools.

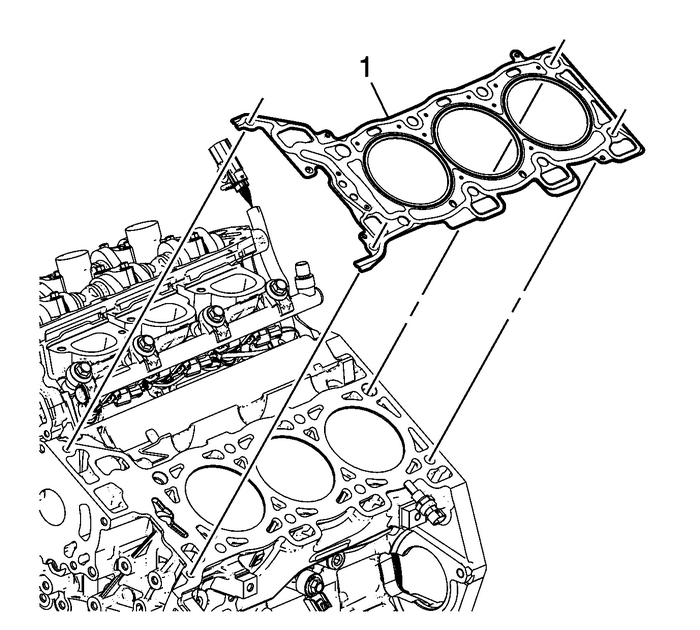

Ensure the cylinder head locating pins are securely mounted in the cylinder blockdeck face.Install a NEW left cylinder head gasket-(1) using the deck face locating pins forretention.

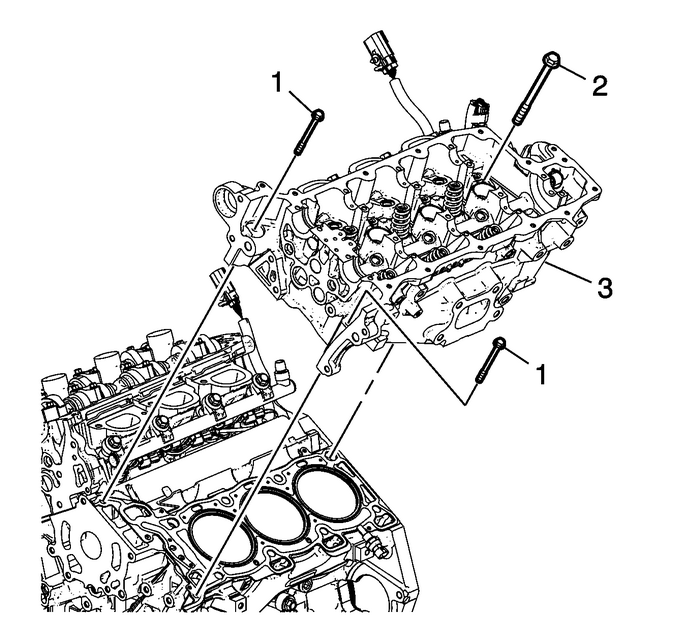

Align the left cylinder head-(3) with the deck face locating pins.Place the left cylinder head in position on the deck face.

Caution:Refer toFastener Caution.

Caution:This vehicle is equipped with torque-to-yield or single use fasteners. Install a NEWtorque-to-yield or single use fastener when installing this component. Failure toreplace the torque-to-yield or single use fastener could cause damage to the vehicleor component.

Note:DO NOT allow oil on the cylinder head bolt bosses.

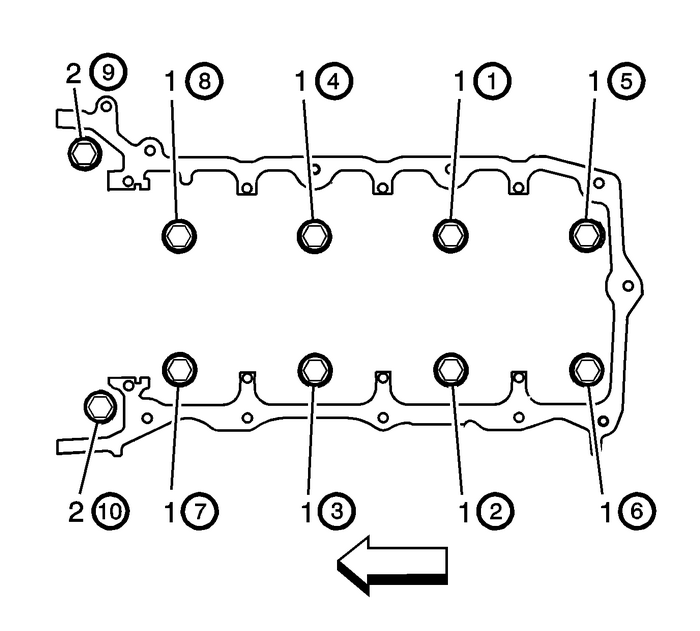

Install the NEW M11 cylinder head bolts-(1).Tighten the M11 cylinder head bolts a first pass in sequence to 30-Y (22-lb-ft).Tighten the M11 cylinder head bolts a second pass in sequence an additional 150-degrees using the EN 45059 meter.Install the 2-NEW front M8 left cylinder head bolts-(2).Tighten the M8 cylinder head bolts a first pass to 15-Y (11-lb-ft).Tighten the M8 cylinder head bolts a second pass in sequence an additional 75-degrees using the EN 45059 meter. Camshaft Position Intake Actuator Replacement Valvetrain Camshaft

Camshaft Position Intake Actuator Replacement Valvetrain Camshaft

Special ToolsEN-45059Angle MeterEN-48749Timing Chain Retention Tool KitEN-48953Camshaft Actuator Locking ToolFor equivalent regional tools, refer toSpecial Tools.Removal ProcedureRemove the air cleane ...

Cylinder Head Installation - Right Side Engine Block Cylinder Head

Cylinder Head Installation - Right Side Engine Block Cylinder Head

Special Tools EN 45059 Angle MeterFor equivalent regional tools, refer toSpecial Tools.Ensure the cylinder head locating pins are securely mounted in the cylinder blockdeck face.Install a NEW right cy ...

Other materials:

Special Tools TPMS

IllustrationTool Number/DescriptionEL-46079Tire Pressure Monitor Diagnostic Toolel50448oec-t5EL-50448Tire Pressure Monitor Sensor Activation Tool ...