Chevrolet Equinox Service Manual: Crankshaft Balancer Cleaning and Inspection Engine Block Cylinder Block Crankshaft

Cleaning Procedure

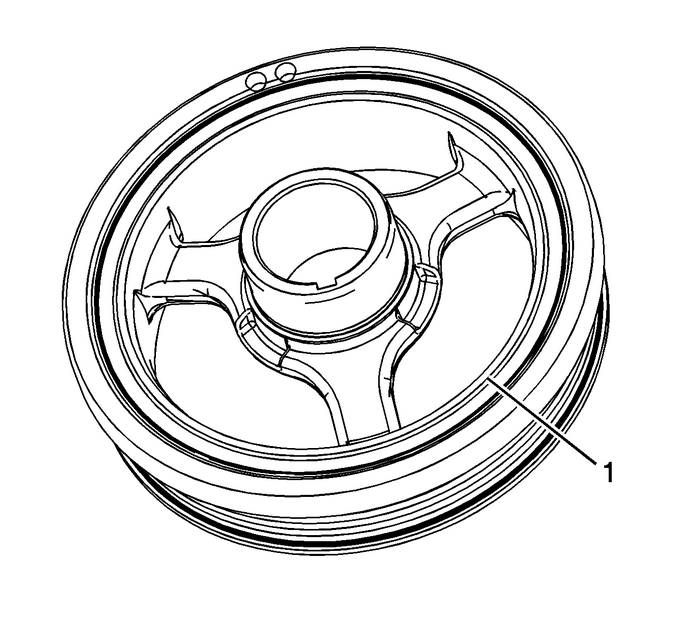

Clean the crankshaft balancer in solvent that is compatiblewith the rubber-(1).

Warning:Refer toSafety Glasses Warning.

Dry the crankshaft balancer with compressed air.Inspection Procedure

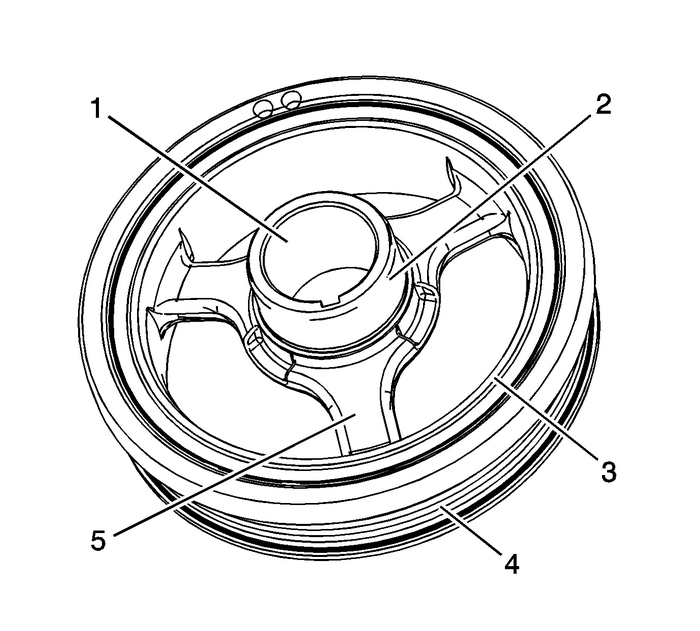

Inspect the crankshaft balancer for the following:Worn or damaged hub-to-crankshaftsurface-(1)Worn, grooved or damaged hub sealsurface-(2)

A crankshaft balancer hub seal surface with excessivescoring, grooves, rust or other damage must be replaced.

Worn, chunking or deteriorated rubber between the hub andpulley-(3)Damaged drive belt ribs-(4)Damaged webs-(5)Repair or replace the crankshaft balancer asnecessary. Camshaft Cover Cleaning and Inspection Valvetrain Camshaft

Camshaft Cover Cleaning and Inspection Valvetrain Camshaft

Cleaning ProcedureClean the camshaft covers in solvent.Warning:Refer toSafety Glasses Warning.Dry the camshaft covers with compressed air.Inspection ProcedureInspect each camshaft cover for the dents ...

Crankshaft and Bearing Cleaning and Inspection Engine Block Cylinder Block Crankshaft

Crankshaft and Bearing Cleaning and Inspection Engine Block Cylinder Block Crankshaft

Cleaning ProcedureClean the following components in solvent:Crankshaft bearingsConnecting rod bearingsCrankshaft journalsCrankpin journalsCrankshaft oil passagesCrankshaft threaded holesWarning:Refer ...

Other materials:

Catalytic Converter Brace Replacement (LEA) Emissions Catalytic Converter

Catalytic Converter Brace ReplacementCalloutComponent NamePreliminary ProceduresRaise and support the vehicle. Refer toLifting and Jacking the Vehicle.Remove the catalytic converter. Refer toCatalytic Converter Replacement.1Catalytic Converter Bracket NutWarning:Refer toExhaust Service Warning.Cauti ...