Chevrolet Equinox Service Manual: Case Cover Assembly Assemble Automatic Transmission Unit

| Table 1: | Fluid Seal Ring Installation |

| Table 2: | 2–6 Clutch Piston Installation |

| Table 3: | Low and Reverse Clutch Piston Installation |

| Table 4: | 2-6 and Low-Reverse Piston Function Inspection |

| Table 5: | Input Speed Sensor Installation |

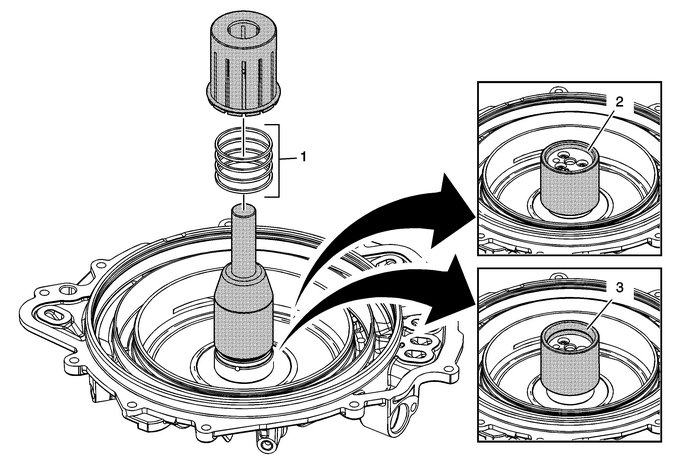

1 | 3–5 Reverse and 4–5–6 Clutch Fluid Seal Ring ProcedurePlace DT-46620-3 which is part of DT-46620 seal installer over the case cover hub and adjust it so that only the bottom seal ring is exposed.Place a NEW fluid seal ring onto DT-46620-3 which is part of DT-46620 seal installer.Use DT-46620-2 which is part of DT-46620 seal installer to push the fluid seal ring down over DT-46620-3 which is part of DT-46620 seal installer into the hub ring groove.Repeat the above steps to install all 4 seal rings, adjusting DT-46620-3 which ispart of DT-46620 seal installer to the appropriate ring groove.Special Tools DT-46620 Seal Installer For equivalent regional tools, refer toSpecial Tools. |

2 | Small Chamfer Up Caution:Do not force the seal installer down over the seals as thiswill roll and damage the seals. The large chamfer is designed tofit over the over stretched seal. Use a hand to help shrink theseal if the seal installer is difficult to install over the sealrings. Procedure Install DT-46620-1 which is part of DT-46620 seal installer with the large chamfer end down over the fluid seal rings and leave DT-46620-1 whichis part of DT-46620 seal installer on the seals for at least 60-seconds. |

3 | Large Chamfer Up ProcedureInstall DT-46620-1 which is part of DT-46620 seal installer with the small chamfer end facing down for at least 60-seconds. This will properlysize the bottom seal ring.Leaving DT-46620-1 which is part of DT-46620 seal installer on the fluid seal rings for an extended period of time could cause a fluid leak onthe initial clutch piston circuit until the seal rings warm up and expand to the properdimension. |

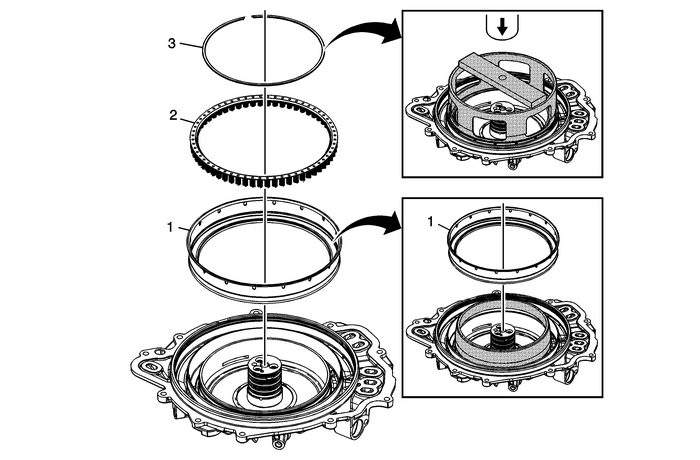

1 | 2–6 Clutch Piston Procedure DT-46621 seal protector prevents the piston seal lip from damage over the retaining ring groove during installation.Apply a thin coat of ATF to the O.D. of DT-46621 seal protector to ease the installation of the piston. Special Tools DT-46621 Seal Protector For equivalent regional tools, refer toSpecial Tools. |

2 | 2–6 Clutch Spring Assembly |

3 | 2–6 Clutch Spring Assembly ProcedureInstall the retaining ring with the opening positioned to the top of the case cover.Place the retainer ring inside DT-46632 spring compressor prior to placing DT-46632 spring compressor onto the spring.Special Tools DT-46632 Spring Compressor For equivalent regional tools, refer toSpecial Tools. |

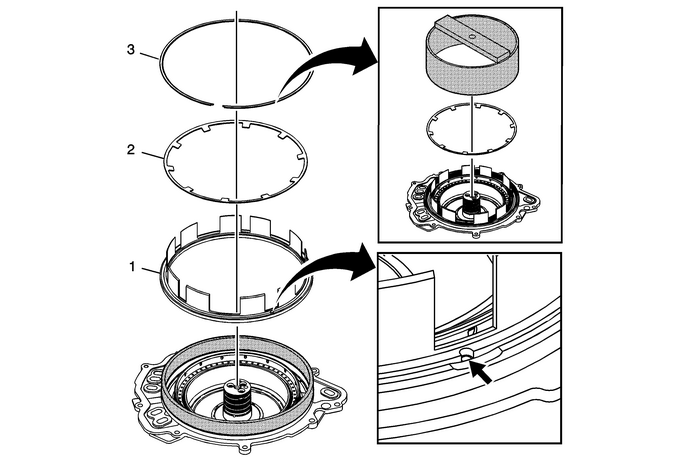

1 | Low and Reverse Clutch Piston Assembly ProcedureInstall the L/R piston with the air bleed positioned at the alignment feature on thecover, using DT-46628-1 seal protector. This will orient the piston fingers with the openings in the case.DT-46628-1 seal protector prevents the piston seal lip from damage during installation. Apply a thin coat ofATF to the I.D. of DT-46628-1 seal protector to ease the installation of the piston.Special Tools DT-46628-1 Piston Seal Protector For equivalent regional tools, refer toSpecial Tools. |

2 | Low and Reverse Clutch Spring |

3 | Low and Reverse Clutch Spring Retaining Ring Note:Do not align the retainer opening with other retaining ring openings. Special Tools DT-46628-2 Spring Compressor For equivalent regional tools, refer toSpecial Tools. |

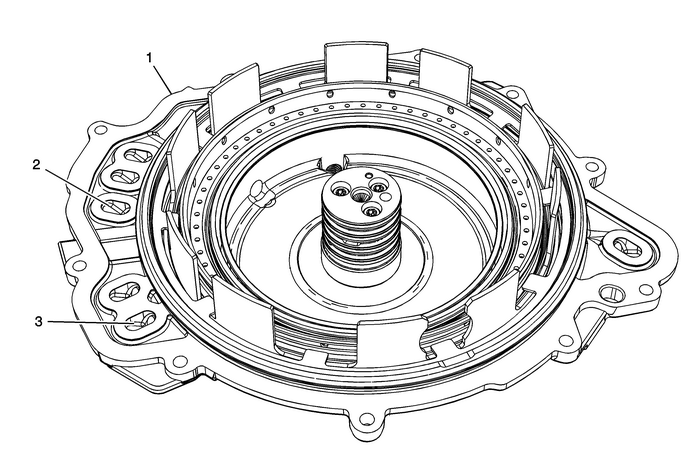

1 | Case Cover Assembly Note:The fluid seal rings should be in place and not damaged. |

2 | 2-6 Clutch Feed Passage Caution:Regulate the air pressure to 40-psi maximum. Highpressure could cause the piston to over travel and damage thepiston seals. Procedure Apply shop air to the 2-6 clutch feed. Observe the 2-6 piston movement. Note:Minimal piston movement and excessive air leaking could indicate damage to the 2-6piston seals or improper assembly. |

3 | Low and Reverse Clutch Feed Passage Caution:Regulate the air pressure to 40-psi maximum. Highpressure could cause the piston to over travel and damage thepiston seals. Procedure Apply shop air to the Low and Reverse clutch feed. Observe the Low and Reverse pistonmovement. Note:Minimal piston movement and excessive air leaking could indicate damage to the Lowand Reverse piston seals or improper assembly. |

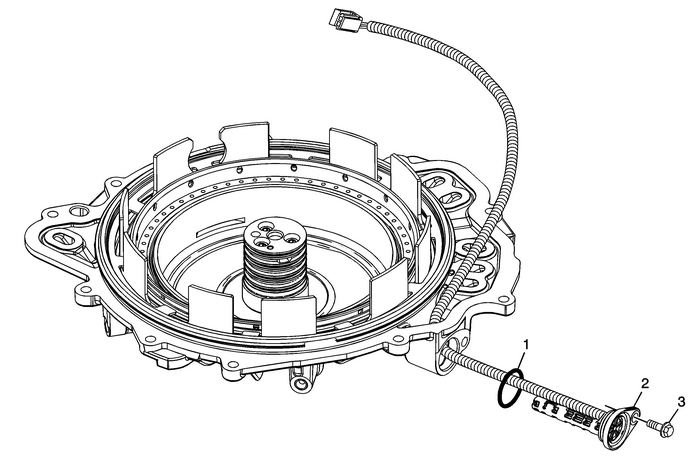

1 | Input Speed Sensor Seal |

2 | A/Trans Input Speed Sensor Assembly |

3 | A/Trans Input Speed Sensor Bolt-M6-x-25 Caution:Refer toFastener Caution. Procedure Apply threadlocker or equivalent to the input speed sensor bolt. Refer toAdhesives, Fluids, Lubricants, and Sealers. Note:The seal is coated with a dry lubricant. If the coating is missing, lubricate theseal with automatic transmission fluid prior to installation. Tighten9-Y (7-lb-ft) |

Transmission Fluid Pump Assemble (6T40/45/50) Automatic Transmission Unit

Transmission Fluid Pump Assemble (6T40/45/50) Automatic Transmission Unit

Table 1: Fluid Pump w/Valve Trains AssembleTable 2: Torque Converter Fluid Seal and Fluid Filter Assembly AssembleFluid Pump w/Valve Trains AssembleFluid Pump w/Valve Trains AssembleCalloutComponent N ...

Transfer Case Assemble Automatic Transmission Unit

Transfer Case Assemble Automatic Transmission Unit

Table 1: Intermediate Drive Shaft AssemblyTable 2: Rear Output Shaft Housing AssemblyTable 3: Output Flange InstallationTable 4: Right Transfer Case, Input Shaft, and Output Drive ShaftInstallationTab ...

Other materials:

Vibration Theory and Terminology

Vibration TheoryThe designs and engineering requirements of vehicles haveundergone drastic changes over the last several years.Vehicles are stiffer and provide more isolation from roadinput than they did previously. The structures of today's stiffervehicles are less susceptible to many of the vibrat ...