Chevrolet Equinox Service Manual: Camshaft Position Actuator Installation - Right Side Intake Valvetrain Camshaft

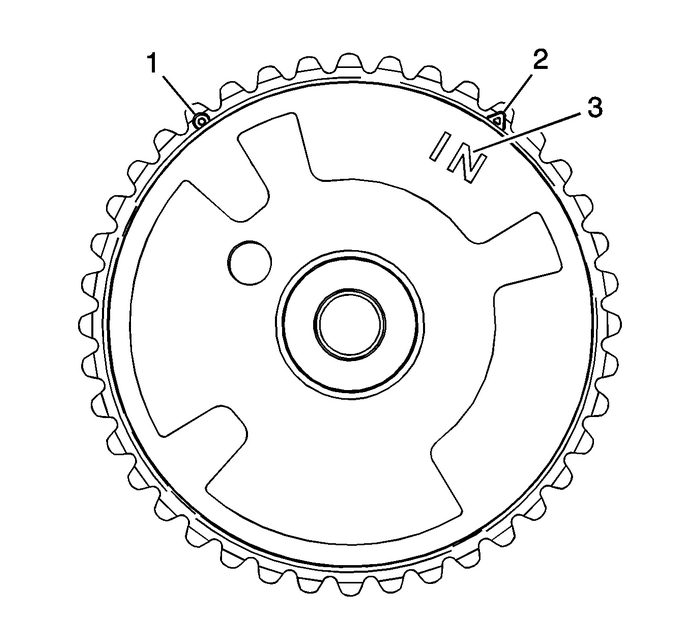

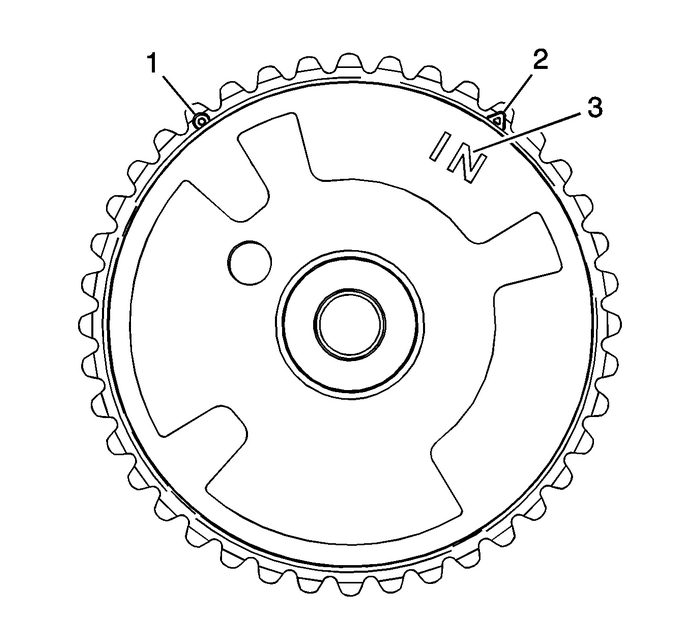

Ensure the proper camshaft position actuator is installed.Observe the body of the camshaft position actuator for the“IN” marking-(3). The marking is foran intake camshaft position actuator.

Caution:Ensure the proper camshaft position actuator is installed inthe correct position. Failure to install the proper camshaftposition actuator can effect engine performance and set an enginecode.

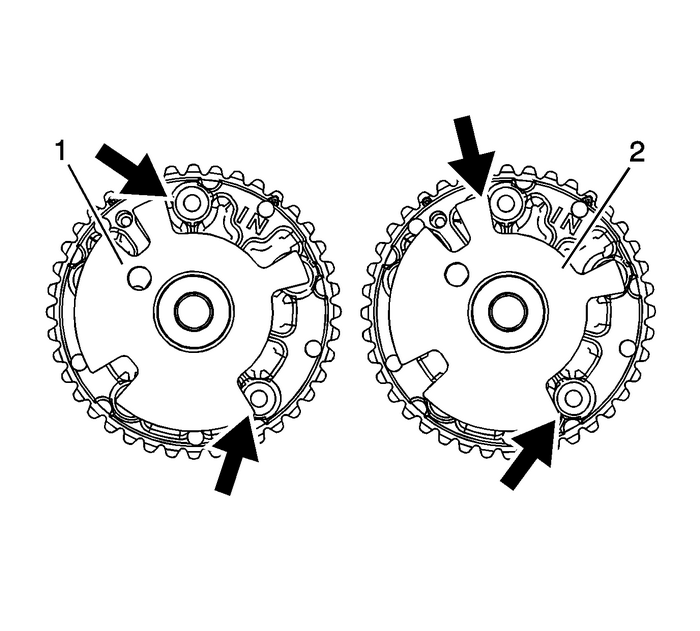

Ensure the proper camshaft position actuator is beinginstalled. The reluctor wheel on the right intake camshaft positionactuator-(1) is indexed in a different position comparedto the left intake camshaft positionactuator-(2).

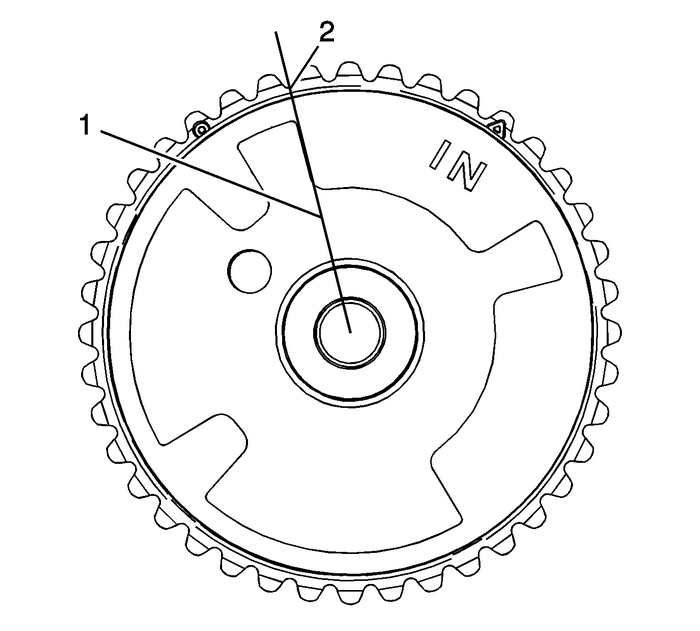

On the right intake camshaft actuator the edge of thereluctor wheel-(1) lines up with thevalley-(2) of the sprocket tooth.

Ensure the proper timing mark is used. Observe the outer ringof the camshaft position actuator for the trianglemarking-(2). The triangle marking is for alignment tothe highlighted timing chain link on the right side of theengine.

Caution:Refer toTorque Reaction Against Timing Drive Chain Caution.

Use an open wrench on the hex cast into the camshaft in orderto prevent camshaft rotation when tightening the camshaft positionactuator bolt.

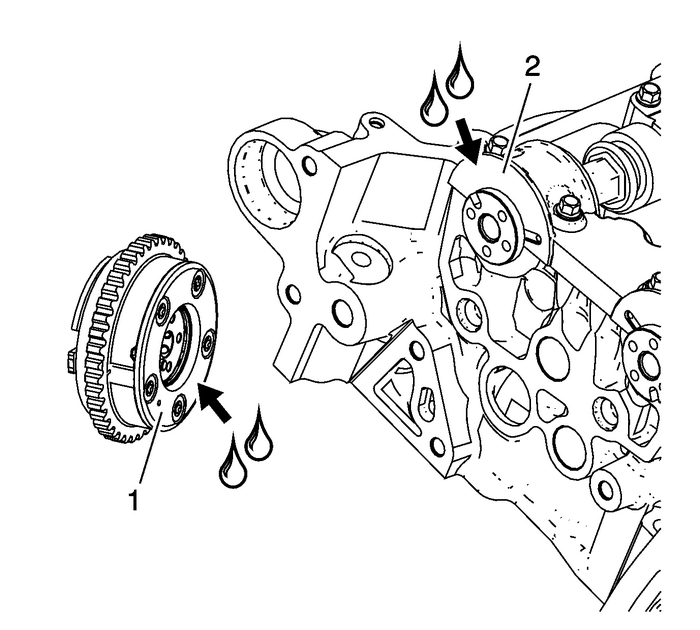

Apply a liberal amount of lubricant to the back of thecamshaft position actuator-(1) and front of the camshaftbearing cap-(2). Refer toAdhesives, Fluids, Lubricants, and Sealersfor recommendedlubricant.

Install the right intake camshaft positionactuator-(2).

Caution:Refer toFastener Caution.

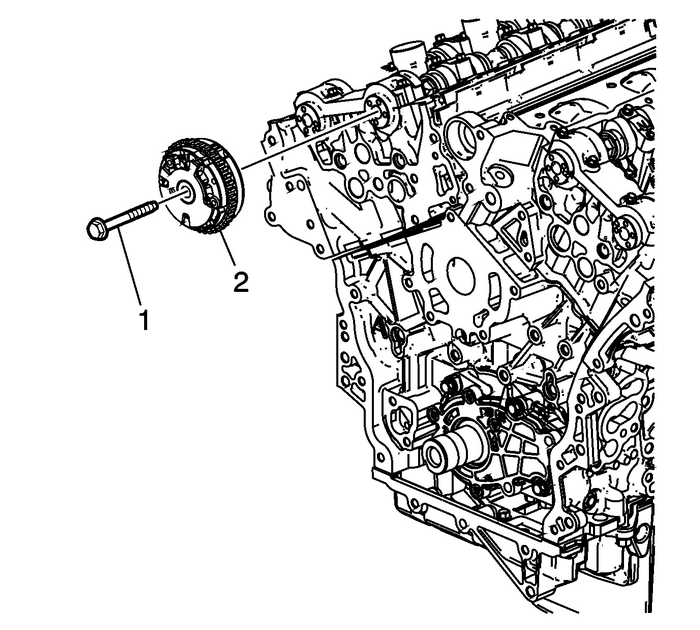

Install the camshaft position actuator bolt-(1)and tighten to58-Y(43-lb-ft). Camshaft Position Actuator Installation - Right Side Exhaust Valvetrain Camshaft

Camshaft Position Actuator Installation - Right Side Exhaust Valvetrain Camshaft

Ensure the proper camshaft position actuator is installed.Observe the body of the camshaft position actuator for the“EX” marking-(1). The marking is foran exhaust camshaft position actuator.Ensure ...

Primary Timing Chain Guide Installation - Upper Valvetrain Valvetrain Timing Timing Belt/Chain

Primary Timing Chain Guide Installation - Upper Valvetrain Valvetrain Timing Timing Belt/Chain

Ensure the upper primary camshaft drive chainguide-(3) is being installed.Install the upper primary camshaft drive chain guides.Caution:Refer toFastener Caution.Install the upper primary camshaft driv ...

Other materials:

Front Differential Drive Pinion Gear and Carrier Installation Automatic Transmission Unit

Front Differential Drive Pinion Gear and Carrier InstallationCalloutComponent Name1Front Differential Carrier AssemblyNote:Install the differential assembly and the pinion gear assembly together to avoid interferencewith the gears during installasion.2Front Differential Drive Pinion (w/Transfer Gear ...