Chevrolet Equinox Service Manual: Camshaft Cleaning and Inspection Valvetrain Camshaft

Special Tools

GE 7872Magnetic Base Dial Indicator

For equivalent regional tools, refer toSpecial Tools.

Cleaning ProcedureClean the camshaft in solvent.Warning:Refer toSafety Glasses Warning.

Dry the camshaft with compressed air.Visual Inspection

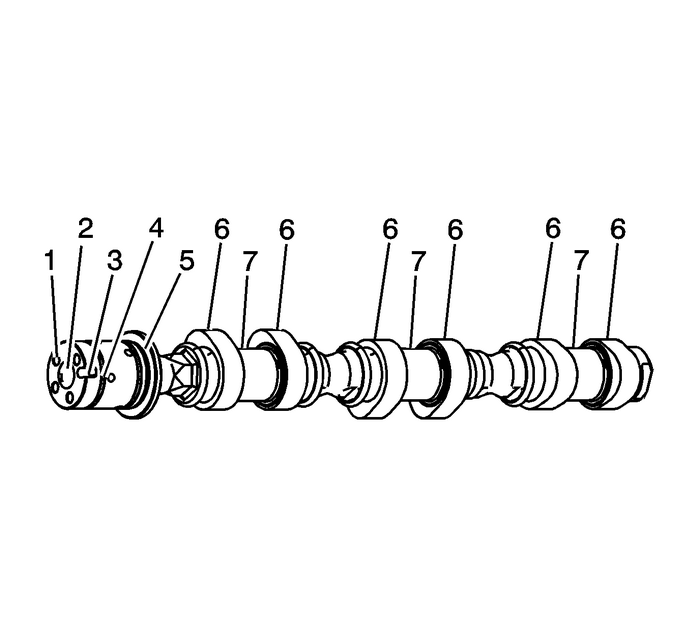

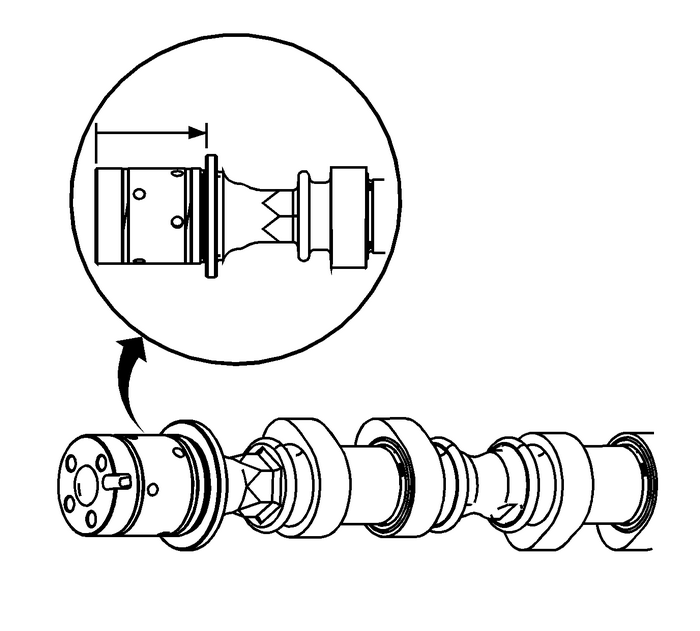

Inspect the camshaft oil feed holes-(1) to thecamshaft position actuator for dirt, debris or blockage.Inspect the threaded hole-(2) for damage.Inspect the camshaft position actuator locatingnotch-(3) for damage or wear.Inspect the camshaft sealing grooves-(4) fordamage.Inspect the camshaft thrust surface-(5) fordamage.Inspect the camshaft lobes-(6) andjournals-(7) for the following conditions:Excessive scoring or pittingDiscoloration from overheatingDeformation from excessive wear, especially the camshaftlobesIf any of the above conditions exist on the camshaft, replacethe camshaft.Camshaft Measurement

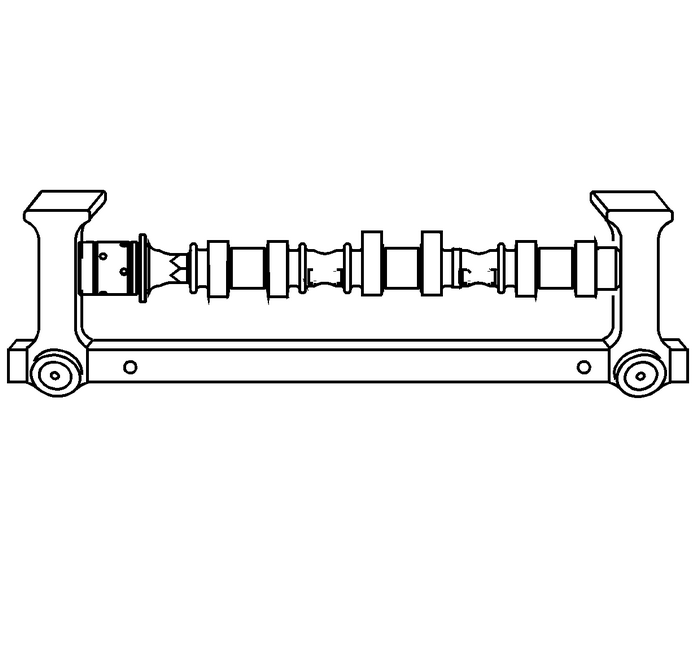

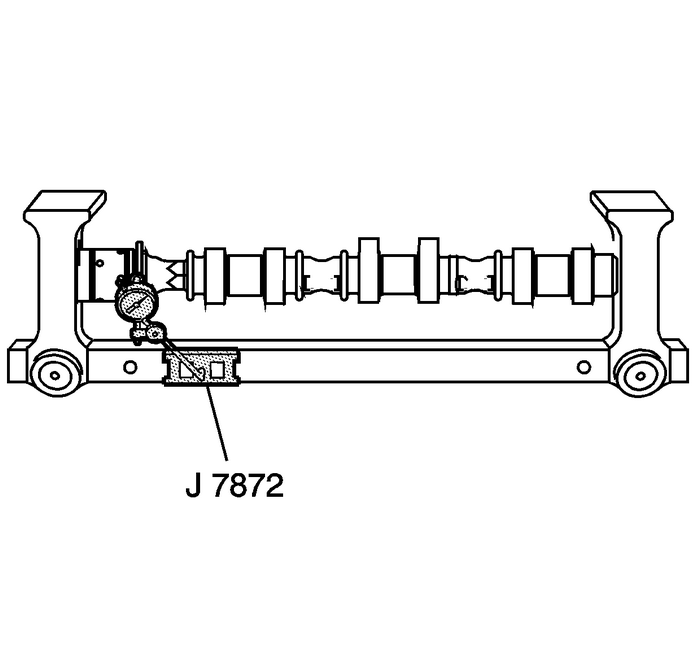

With the camshaft in a suitable fixture, measure the camshaftfor wear.

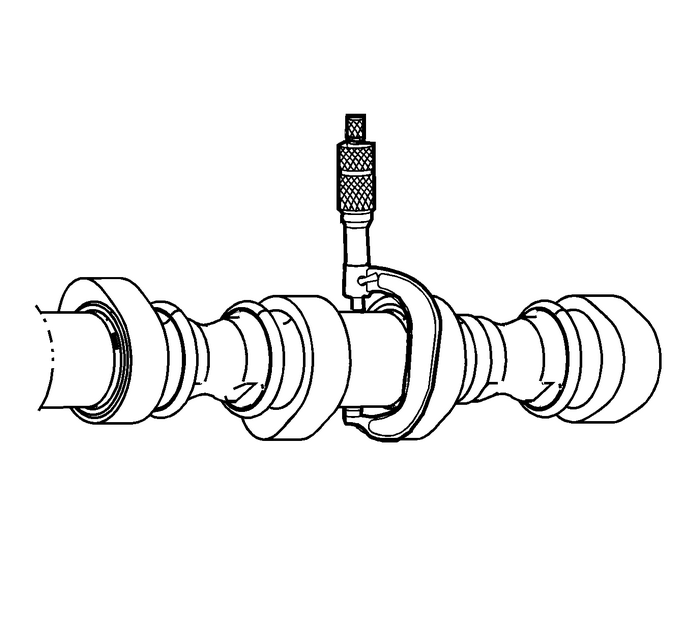

Measure the camshaft journals for diameter andout-of-round using an outside micrometer.Refer toEngine Mechanical Specifications.If the diameter is smaller than specifications, replace thecamshaft.If the out-of-round exceedsspecifications, replace the camshaft.

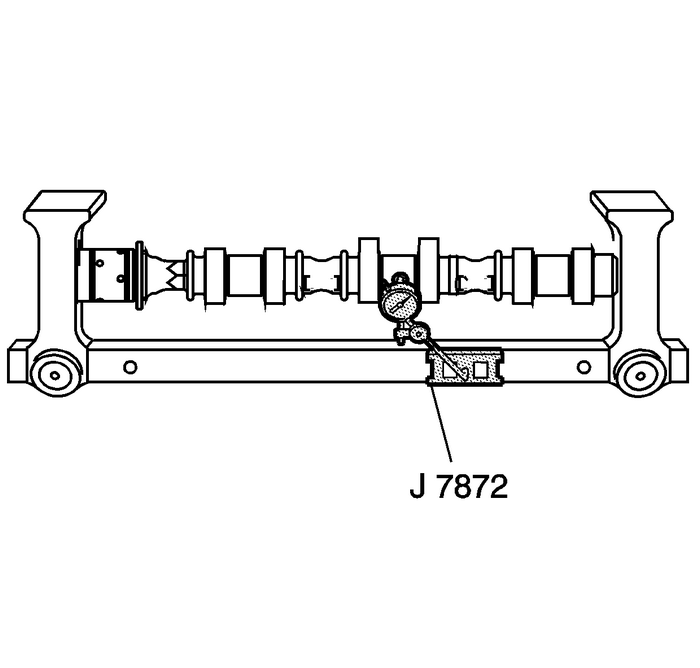

Measure the camshaft runout using theGE 7872indicator. Refer toEngine Mechanical Specifications.

Measure the camshaft thrust width for wear using a depthmicrometer. Refer toEngine Mechanical Specifications.

Measure the camshaft thrust wall surface for runout usingGE 7872indicator. Refer toEngine Mechanical Specifications.If the camshaft is damaged or worn beyond specifications,replace the camshaft. No machining of the camshaft isallowed.

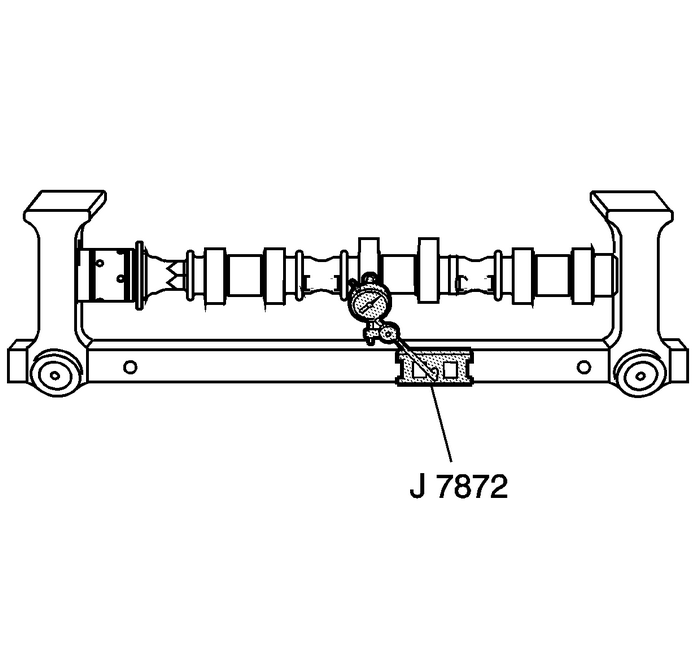

Measure the camshaft lobes for wear using theGE 7872indicator.

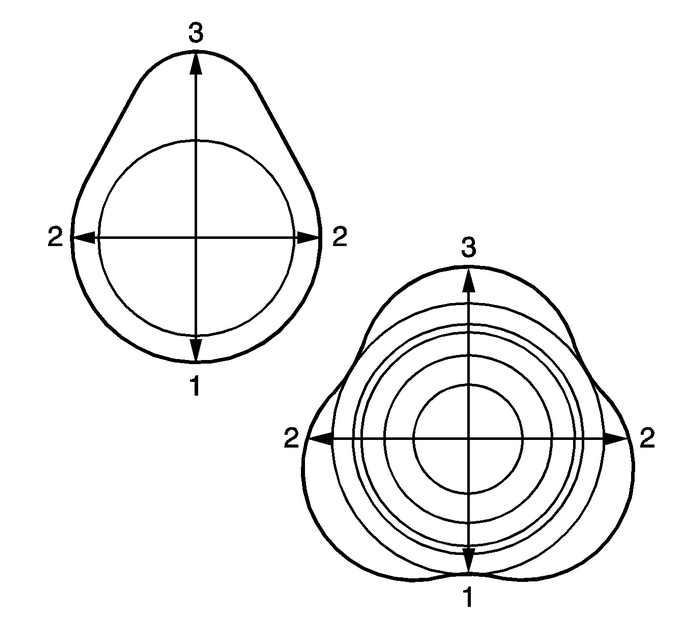

Place theGE 7872indicatorwith the indicator tip on the base circle-(1)of the camshaft lobe.Place theGE 7872indicatorat zero.Rotate the camshaft until the indicator tip is at the highestpoint-(3) on the lobe. This reading is the lift of thecamshaft lobe. Refer toEngine Mechanical Specifications.If the indicated measurement is significantly lower thanthese specifications, replace the camshaft or engine performancewill be reduced.

Crankshaft and Bearing Removal Engine Block Cylinder Block Crankshaft

Crankshaft and Bearing Removal Engine Block Cylinder Block Crankshaft

Special ToolsGE 6125-1BSlide Hammer AdapterEN 49102Crankshaft Bearing Cap RemoverFor equivalent regional tools, refer toSpecial Tools.Crankshaft End Play MeasurementPlace a dial indicator at the crank ...

Crankshaft and Bearing Cleaning and Inspection Engine Block Cylinder Block Crankshaft

Crankshaft and Bearing Cleaning and Inspection Engine Block Cylinder Block Crankshaft

Special ToolsGE-7872Magnetic Base Dial Indicator SetFor equivalent regional tools, refer toSpecial Tools.Note:Use care when handling the crankshaft. Avoid damage to thebearing surfaces or the lobes of ...

Other materials:

Convex Mirrors

Warning

A convex mirror can make things,

like other vehicles, look farther

away than they really are. If you

cut too sharply into the right lane,

you could hit a vehicle on the

right. Check the inside mirror or

glance over your shoulder before

changing lanes.

The ...