Chevrolet Equinox Service Manual: Air Conditioning O-Ring Seal Replacement

Removal Procedure

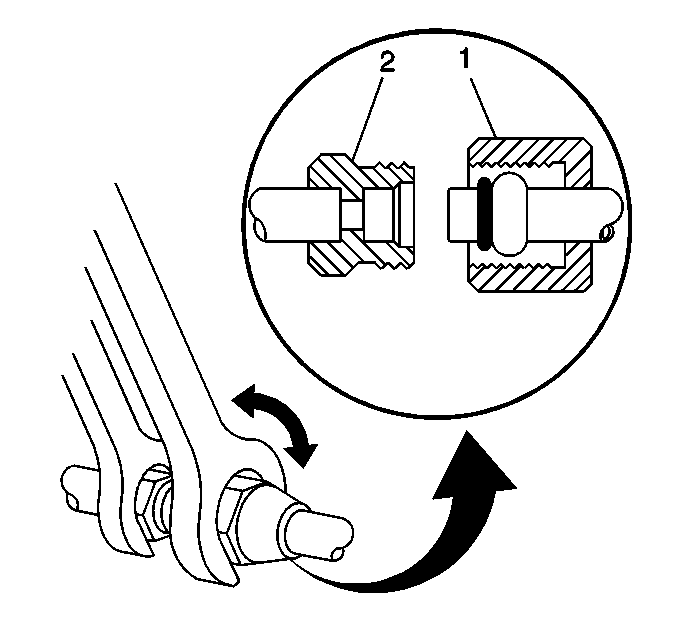

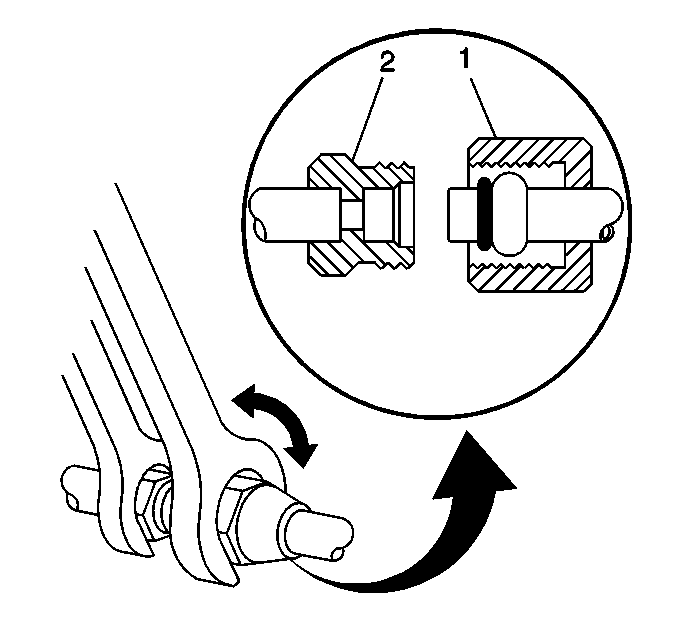

Disassemble the A/C refrigerant components. Refer to theappropriate repair procedureFor compression style fittings use a back up wrench on thefitting (2) and loosen the fitting nut (1).For banjo style fittings remove the bolt retaining the banjotype fitting.Remove the O-ring seal from the A/C refrigerantcomponent.Inspect the O-ring seal for signs of damage to help determinethe root cause of the failure.Inspect the A/C refrigerant components for damage or burrs.Repair if necessary.

Note:Cap or tape the open A/C refrigerant components immediatelyto prevent system contamination.

Cap or tape the A/C refrigerant components.Discard the O-ring seal.Installation ProcedureInspect the new O-ring seal for any sign or cracks, cuts, ordamage. Replace if necessary.Remove the cap or tape from the A/C refrigerantcomponents.Using a lint-free clean, dry cloth, carefully clean thesealing surfaces of the A/C refrigerant components.Note:DO NOT allow any of the mineral base 525-viscosityrefrigerant oil on the new O-ring seal to enter the refrigerantsystem.

Lightly coat the new O-ring seal with mineral base525-viscosity refrigerant oil.Note:DO NOT reuse O-ring seals.

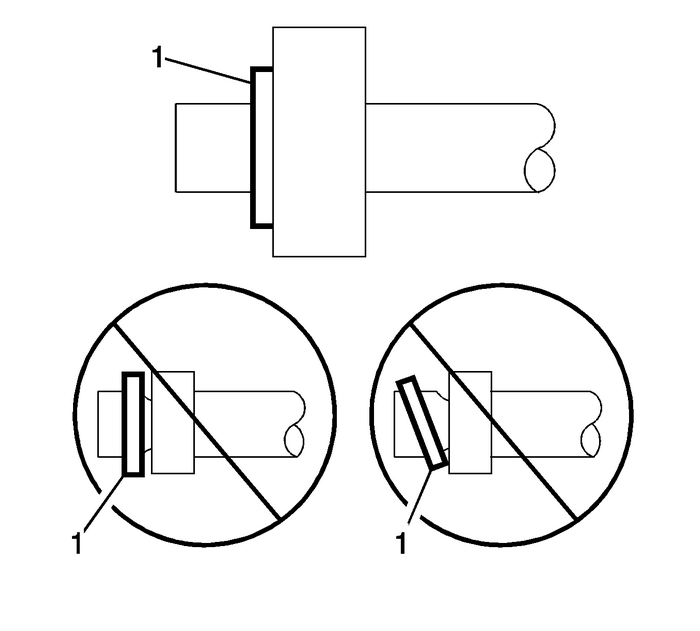

Carefully slide the new O-ring seal onto the A/C refrigerantcomponent.

The O-ring seal must be fully seated.

Assemble the A/C components.

Refer to the appropriate repair procedure.

For compression style fittings use a back up wrench on thefitting (2) and tighten the fitting nut (1) tospecification.For banjo style fittings install the bolt retaining the banjotype fitting and tighten to specification. Refrigerant System Specifications

Refrigerant System Specifications

Refrigerant System SpecificationsApplicationSpecificationMetricEnglishPAG Oil GM P/N-12378526 for United StatesPAG Oil GM P/N-88900060 for CanadaAbrupt Refrigerant Loss65-ml2.20-ozCompressor Replaceme ...

Floor Air Outlet Replacement - Center

Floor Air Outlet Replacement - Center

Removal ProcedureRemove the front floor console. Refer toFront Floor Console Replacement.Slide the center floor air outlet duct forward enough toclear the rear floor air outlet duct, and then up, and ...

Other materials:

Intake Manifold Disassemble Intake and Forced Induction Intake Manifold

Remove the throttle body bolts-(1).Remove the throttle body-(2).Remove and discard the throttle bodyseal-(3).Loosen the evaporative-(EVAP) solenoidbolt.Remove the EVAP solenoid-(1).Remove the manifold absolute pressure-(MAP) sensorbolt-(1).Remove the MAP sensor-(2).Remove the lower intake manifold b ...