Chevrolet Equinox Service Manual: #01-08-51-003D: Application of Anti-Corrosion Materials - (Sep 16, 2013)

| Subject: | Application of Anti-Corrosion Materials |

|

| Models: | 2014 and Prior GM Cars and Trucks | |

This bulletin has been revised to add the 2013-2014 model years and update the product/suppliertables. Please discard Corporate Bulletin Number♦01-08-51-003C.

After a collision, some vehicle structure areas such as frame rails, cross-membersand rocker panel sections may need to be repaired. In most cases, the anti-corrosionmaterials need to be removed to perform these repairs. These materials are classifiedinto two types: Closed Cavity coatings and Undercoat coatings. The primary differenceis the way the products set up or “dry.” Both are intended to protect the surfacethey are appliedto from corrosion caused by water, salt water or Magnesium Chloride blended de-icingcompounds used to thaw icy winter roads. They also can provide a measure of sounddeadening.

The Closed Cavity coatings remain sticky to the touch and will seep into seams initiallyand over extended periods of time. Closed Cavity coatings provide the best corrosionprotection inside of rocker panel sections, pillar sections, frame rails, cross-members,doors, rear compartment lids and closed areas of hoods – anywhere that is concealedor closed off to exterior surfaces.

The Undercoat coatings are “dry to the touch” and offer the best corrosion protectionand sound deadening for floor pans, wheelhouses, inside rear compartment and underhoodareas – anywhere the coated surface is exposed.

Below is a listing of products and coatings that GM believes to be reliable. Whileothers may exist, we have found these products, or equivalents to them, can be usedwith satisfactory results. Always use these products according to their manufacturer’srecommendations.

Prep Treatment and First Stage Coating

It some instances, repairs may be needed for bare metal or minor surface rust conditions.The phosphate treatment and paint listed below are highly recommended and offer thebest corrosion resistance, when applied as a base coat for the Undercoating/ClosedCavity coatings.

The following products are available from *Lloyds. Contact them at 1-800-361-6766or at sales@lloydslaboratories.com.

Pure Prep™ 25418 | Metal Surface Preparation | 10♦oz. Liquid - Phosphate Cleaner/Conditioner |

Kryptonite 36502 | Metal Treatment - Life Long Rust Protection | 14♦oz. Aerosol |

Undercoating and Closed Cavity Coatings

The following products are available from *Automotive International/Valugard. Contactthem at 1-800-543-7156, or at www.valugard.net.

VG-104 | WAX/SOLVENT BASED UNDERCOAT | Traditional Wax/Solvent based Undercoating available in aerosol or spray gun canister Meets OE specifications for corrosion resistance |

VG-076M | HYBRID (SOLV. / WATER) UNDERCOAT | Meets OE specifications for corrosion resistance |

VG-140 | WATER BASED UNDERCOAT | Meets OE specifications for corrosion resistance |

VG-101 | WAX BASED CLOSED CAVITY COATING | Meets OE specifications for corrosion resistance |

VG-UCG | CANISTER UNDERCOATING GUN | High quality undercoating gun uses canister packaging of undercoating |

VG-CRG | CANISTER CLOSED CAVITY COATING GUN | High quality closed cavity coating gun uses canister packaging of coating and comeswith 30" inner panel application tube with nozzle |

The following products are available through your local *3M® distributor. Informationabout 3M® product retailers in your area may be obtained at 1-866-364-3577 or at www.mmm.com/automotive.

08804 | No Cleanup Water-Based Undercoating - Black | Coarse texture SBR rubber and acrylic applied with 3M No-Cleanup Gun 08801 |

08964 | No Cleanup Undercoating - Black | Smooth texture SBR rubber applied with 3M No-Cleanup Gun 08801 |

08881 | 16♦oz aerosol Undercoating | Calcium Carbonate and asphalt based undercoating |

08882 | 17♦oz aerosol Underseal™ Undercoating - Black | Rubber based, paintable undercoating |

08883 | 19.7♦oz aerosol Rubberized Undercoating - Black | Synthetic polymer based undercoating |

08891 | Rust Fighter–1 Amber Closed Cavity Coating — quart canister | Synthetic Resin remains tacky seeps into crevices; Applied with 3M Applicator Gun08997 and Application Wand 08998 |

08892 | Rust Fighter–1Amber Closed Cavity Coating – 24♦oz aerosol | Synthetic Resin remains tacky seeps into crevices; aerosol can |

08801 | No Cleanup Undercoating Gun | — |

The following products are available from *Crest Industries, Inc. at 1-800-822-4100or www.crestauto.com.

AH-C | HONEY COAT/WAX BASED CLOSED CAVITY COATING | 16.5♦ OZ AEROSOL CAN AMBER COLORED SEEPS INTO CREVICES AND REMAINS PLIABLE 36" spray wand with 360 degree nozzle available (WA-HC) |

BZ-BAC BZ-BACB | AMBER COAT/WAX BASED CLOSED CAVITY COATING | GALLON - AMBER COLORED (BZ-BAC) OR BLACK (BZ-BACB) SEEPS INTO CREVICES AND REMAINSPLIABLE APPLIED WITH WZ-GRP GUN & SIPHON HOSE Flexible spray wand also available (WA-ND) |

AC-R | RUBBER COAT/RUBBER BASED UNDERCOATING, PAINTABLE | 17.75♦OZ AEROSOL |

AR-C | SUPER RUBBER COAT/LOW V.O.C. RUBBER BASED UNDERCOATING, PAINTABLE | 17.75♦OZ AEROSOL |

BA-C | AUTO COAT/RUBBER BASED UNDERCOATING, PAINTABLE | 28.7♦FL. OZ. CONE-TOP CAN & GALLON APPLIED WITH GU-C UNDERCOATING GUN |

GU-C | UNDERCOATING GUN | ATTACHES TO BA-C CONE-TOP CAN |

WZ-GRP | GUN & SIPHON HOSE | USED WITH BZ-BAC & BZ-BACB |

WA-ND | FLEXIBLE SPRAY WAND | USED WITH WZ-GRP |

The following products are available from *Kent Automotive. Contact them at 1-888-YES-KENT(888-937-5368) or at www.kent-automotive.com.

P60305 | Wax Based Inner Panel Rustproofer — CLOSED CAVITY COATING | 24♦oz. Aerosol (can apply with 36" wand and 360 degree nozzle kit) |

KT14912 | Rubber Guard Low VOC Rubber Based Undercoating | 24♦oz. Aerosol (can apply with 36" wand and 360 degree nozzle kit) |

KT14725 | Aerosol Extension Wand Kit | 36" wand and 360 degree nozzle |

KT14796 | Rubber Guard Low VOC Rubber Based Undercoating | QUART — Applied with undercoating gun |

P30025 | Siphon Feed Gun | — |

P86079 | 360 Degree Wand for siphon feed gun | — |

The following product is available from *Daubert. For U.S. Dealers only, contact them at 1-800-914-0034 (inside the U.S. only) or at www.daubertchemical.com.

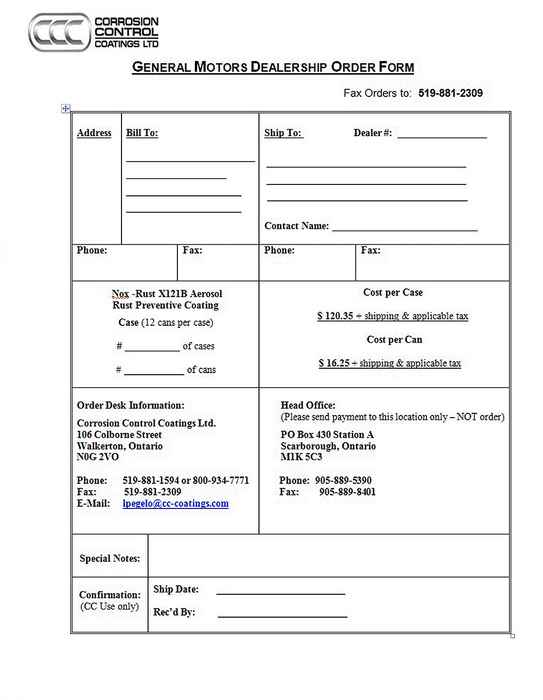

Canadian Dealers only must contact the Daubert distributor in Canada, Corrosion Control Coatings Ltd, byfaxing the form below to 519-881-2309.

Nox-Rust® X-121B | One Coat Rust Preventive Coating | Aerosol -Dries to firm, wax-like film |

*We believe these sources and their products to be reliable. There may be additionalmanufacturers of such material. General Motors does not endorse, indicate any preferencefor or assume any responsibility for the products from these firms or for any suchitems which may be available from other sources.

Important:ONLY Canadian Dealers should use this form.

GM bulletins are intended for use by professional technicians,NOT a "do-it-yourselfer". They are written to inform thesetechnicians of conditions that may occur on some vehicles, or toprovide information that could assist in the proper service of avehicle. Properly trained technicians have the equipment,tools, safety instructions, and know-how to do a job properly andsafely. If a condition is described, DO NOT assume that thebulletin applies to your vehicle, or that your vehicle will havethat condition. See your GM dealer for information on whetheryour vehicle may benefit from the information. |

| WE SUPPORT VOLUNTARY TECHNICIAN CERTIFICATION |

Structure Identification

Structure Identification

Structure Identification (Coupe)NumberDescriptionMaterialsProcedure1Radiator Support AssemblyMild SteelFront End Upper Tie Bar Replacement2Front Wheelhouse AssemblyMild SteelFront Wheelhouse Panel Rep ...

#13-00-89-004C: Car and Truck Fix it Right the First Time Issues - (Oct 10, 2013)

#13-00-89-004C: Car and Truck Fix it Right the First Time Issues - (Oct 10, 2013)

Subject:Car and Truck Fix it Right the First Time IssuesModels: 2014 and Prior GM Cars and Trucks This bulletin has been revised to include updated information. Please discard CorporateBulletin Nu ...

Other materials:

Driver or Passenger Seat Head Restraint Guide Replacement Seats

Driver or Passenger Seat Head Restraint Guide ReplacementCalloutComponent NamePreliminary ProcedureRemove the front seat head restraint. Refer toDriver or Passenger Seat Head Restraint Replacement.1Front Seat Head Restraint GuideProcedureUsing a suitable flat-bladed tool, slide the tool between ther ...