Chevrolet Equinox Service Manual: Valve and Seat Grinding Seats

Valve Cleaning ProcedureUse soft bristle wire brush to clean any carbon build-up fromthe valve head. DO NOT use a wire brush on any part of the valvestem. The valve stem is chrome plated to provide enhanced wearcharacteristics. Wire brushing the stem could remove the chromeplating.Thoroughly clean the valve with solvent and wipe dry.Valve Visual Inspection Procedure

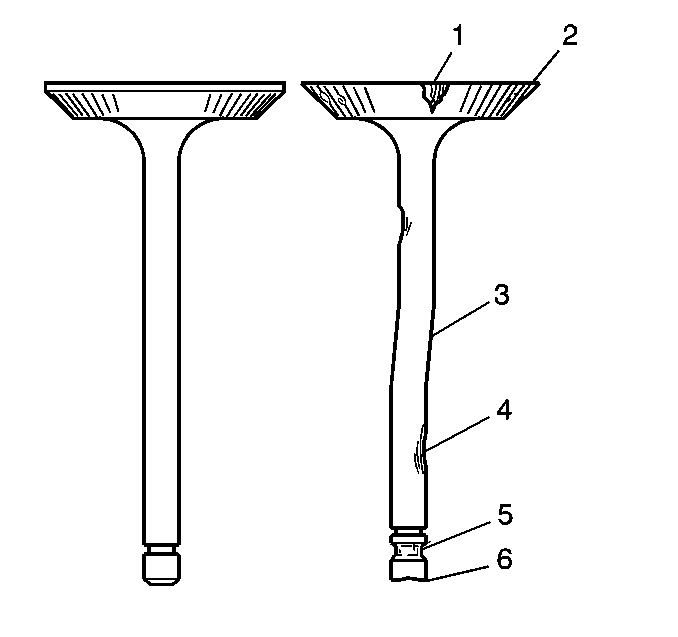

Inspect the valve for damage from the head to tip for thefollowing conditions:Pitting in the valve seat area-(1)Lack of valve margin-(2)Bending in the valve stem-(3)Pitting or excessive wear in the stem-(4)Worn valve key grooves-(5)Worn valve tip-(6)Replace the valve if any of these conditions exist.Valve Measurement Overview

Note:The following measurement and reconditioning procedures mustbe followed to ensure proper engine performance.

Proper valve service is critical to engine performance.Therefore, all detailed measurement procedures must be followed toidentify components that are out of specification.If the measurement procedures reveal that the valve seat mustbe reconditioned, it is critical to perform the measurementprocedures after reconditioning. Valves for E85-compatible enginesCANNOT be reconditioned. Any grinding, lapping, wire-brushing orother similar procedure will damage or destroy the coating thatgives the valve the E-85 compatible features. If an E85-compatiblevalve is out of specification in any area, replace it.Valve Seat Width Measurement Procedure

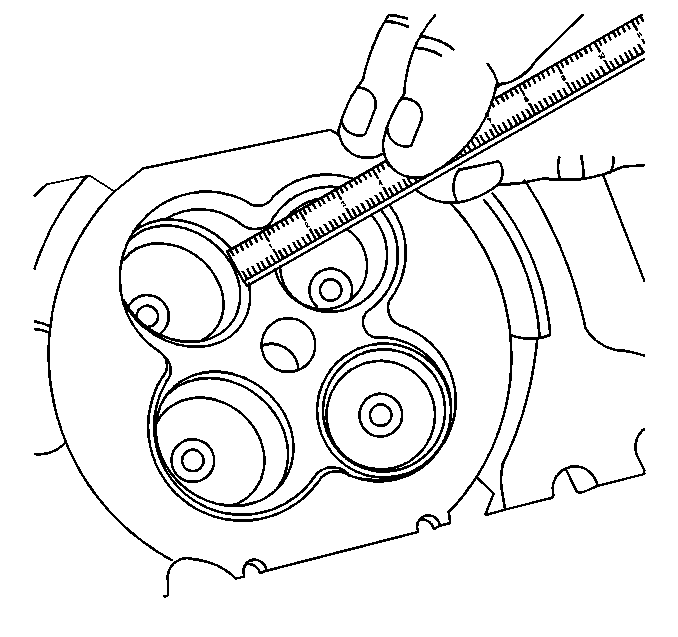

Measure the valve seat width in the cylinder head using aproper scale.

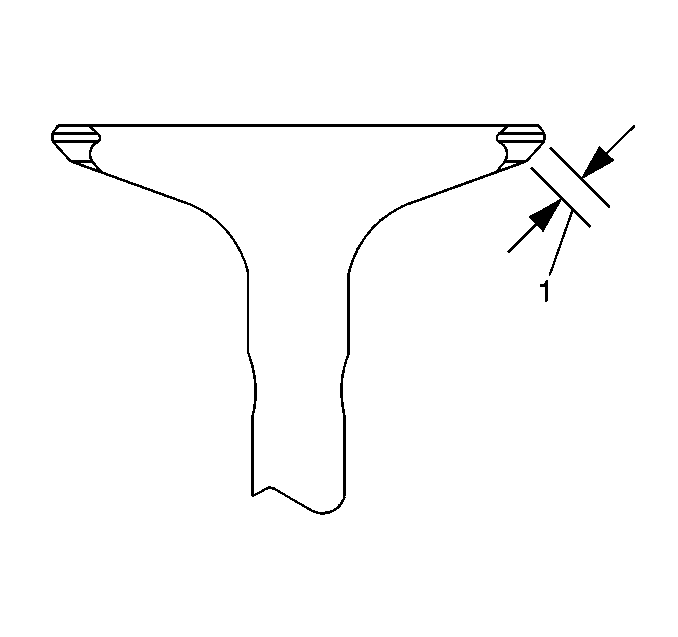

Measure the seat width on the valve face-(1) usinga proper scale.

Note:The seat contact area must be at least0.5-mm-(0.020-in) from the outerdiameter (margin) of the valve. If the contact area is too close tothe margins, the valve must be replaced.

Compare your measurements with the specifications listed inEngine Mechanical Specifications.If the seat widths are acceptable, check the valve seatroundness using the Valve Seat Roundness MeasurementProcedure.If the seat width is not acceptable, you must replace thevalve. Proper valve seat width is critical to providing the correctamount of valve heat dissipation.Valve Seat Roundness Measurement ProcedureMeasure the valve seat roundness using a dial indicatorattached to a tapered pilot installed in the guide. The pilotshould have a slight bind when installed in the guide.Caution:The correct size pilot must be used. Do not use adjustablediameter pilots. Adjustable pilots may damage the valveguides.

Compare your measurements with the specifications listed inEngine Mechanical Specifications.If the valve seat exceeds the roundness specification, youmust replace the valve.If new valves are being used, the valve seat roundness mustbe within 0.05-mm (0.002-in).Valve Margin Measurement Procedure

Measure the valve margin using an appropriate scale.Reference the specifications in this section for minimumvalve margin and compare them to your measurements.If the valve margins are beyond specification, replace thevalves.If the valve margins are within specification, test the valvefor seat concentricity using the Valve-to-Seat ConcentricityMeasurement Procedure.Valve-to-Seat Concentricity Measurement Procedure

Note:

Checking the valve-to-seat concentricity determines whetherthe valve and seat are sealing properly.You must measure the valve face and the valve seat to ensureproper valve sealing.

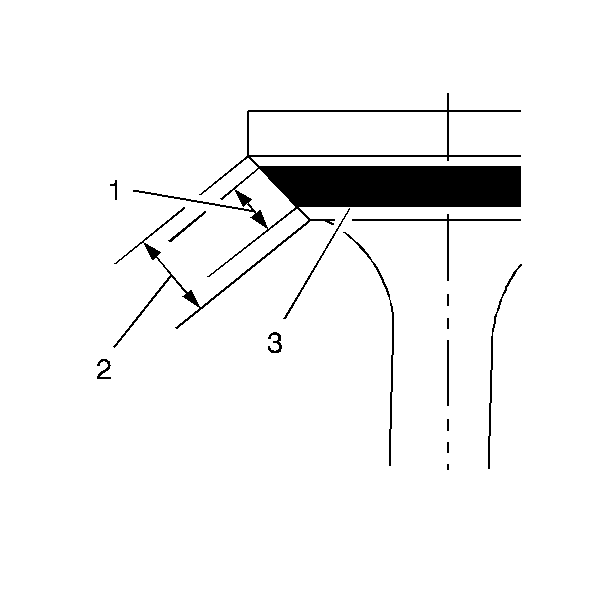

Coat the valve face lightly with bluedye-(3).Install the valve in the cylinder head.Turn the valve against the seat with enough pressure to wearoff the dye.Remove the valve from the cylinder head.Inspect the valve face.If the valve face is concentric, providing a properseal-with the valve stem, a continuous mark will be madearound the entire face-(1).

Note:The wear mark MUST be at least 0.5-mm(0.020-in) from the outer diameter, the margin, of thevalve. If the wear mark is too close to the margin, the seat mustbe reconditioned to move the contact area away from themargin.

If the face is not concentric with the stem, the mark willNOT be continuous around the valve face. The valve should bereplaced and the seat must be reconditioned using the Valve andSeat Reconditioning Procedure.Valve and Seat Reconditioning Procedure

Note:

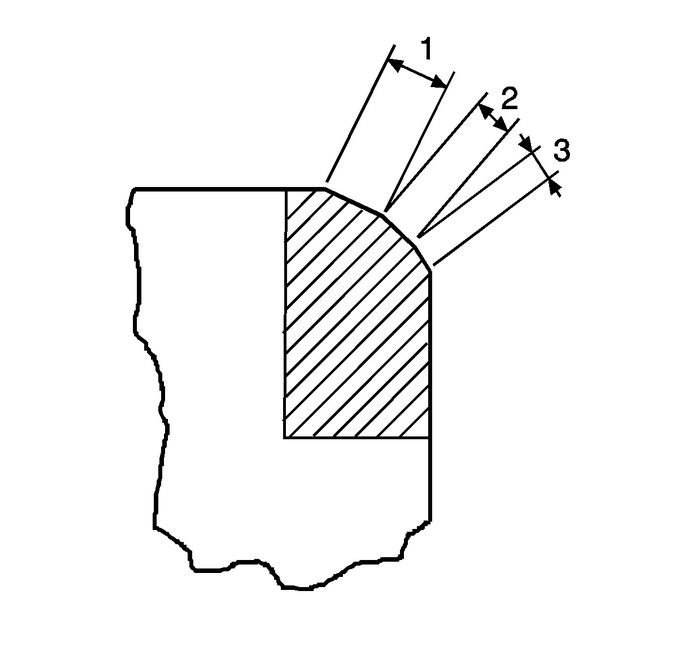

If the valve seat width, roundness or concentricity is beyondspecifications, you must grind the seats in order to ensure properheat dissipation and prevent the buildup of carbon on theseats.A NEW valve must be used with any reconditioned seat.Grind the valve seats-(2) to the proper anglespecification listed inEngine Mechanical Specifications.Using the proper angle specification listed inEngine Mechanical Specifications, grind, relieve, the valveseats-(1) to correctly position the valve seatingsurface-(2) to the valve.Using the proper angle specification listed inEngine Mechanical Specifications, grind, undercut, the valveseats-(3) to narrow the valve seat widths to thespecifications listed inEngine Mechanical Specifications.When grinding the seats, grind off as little material aspossible. Cutting valve seat results in lowering the valve springpressure.Install the valve in the cylinder head. Do not lap the valvesunder any condition, whether the valves are new or used.After obtaining the proper valve seat width in the cylinderhead, you must re-measure the valve stem height using the ValveStem Height Measurement Procedure.If the valve stem height is acceptable, test the seats forconcentricity using the Valve-to-Seat Concentricity MeasurementProcedure.Valve Stem Height Measurement Procedure

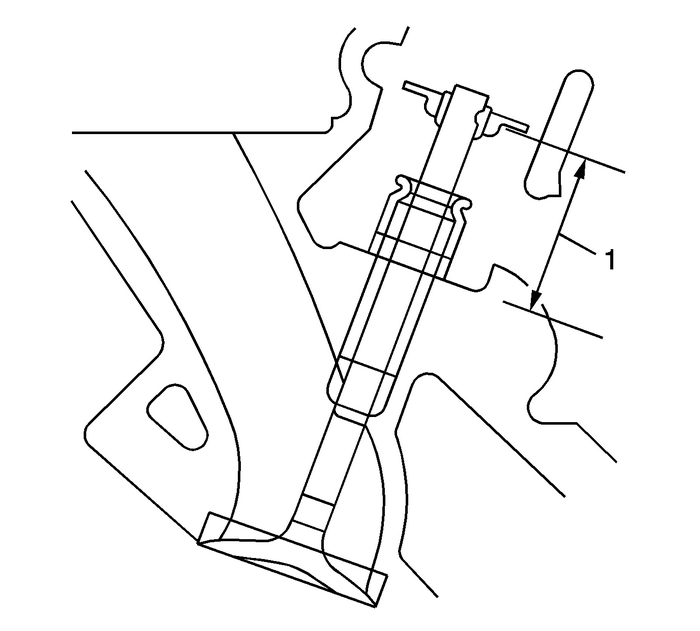

Note:To determine the valve stem height measurement, measure fromthe valve spring seat to the valve spring retainer.

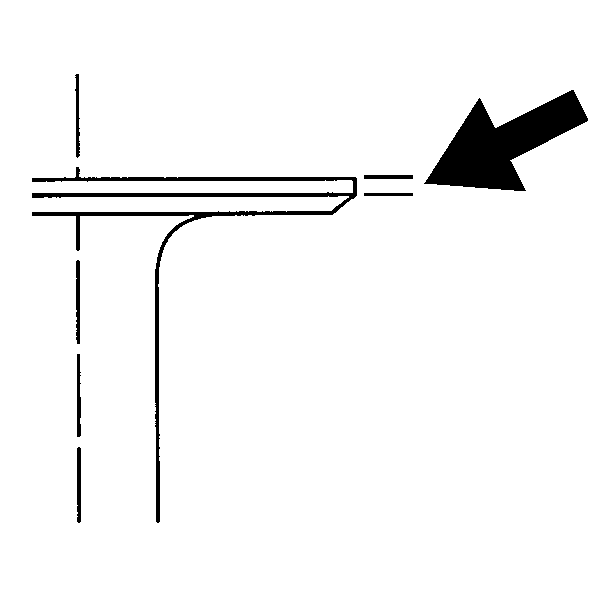

Install the valve into the valve guide.Ensure the valve is seated to the cylinder head valveseat.Install the valve stem oil seal.Install the valve spring retainer and valve stemlocks.Measure the distance-(1) between the cylinder headto the bottom of the valve spring retainer. Refer toEngine Mechanical Specifications.If the maximum height specification is exceeded, a new valveshould be installed and the valve stem height re-measured.Caution:DO NOT grind the valve stem tip. The tip of the valve ishardened and grinding the tip will eliminate the hardened surfacecausing premature wear and possible engine damage.

Caution:DO NOT use shims in order to adjust valve stem height. Theuse of shims will cause the valve spring to bottom out before thecamshaft lobe is at peak lift and engine damage couldresult.

If the valve stem height still exceeds the maximum heightspecification, the cylinder head must be replaced. Heated Seat Control Module Programming and Setup Heated Cooled System

Heated Seat Control Module Programming and Setup Heated Cooled System

The seat heating control module must be programmed with theproper calibration software. The module stores and utilizes thisinformation however if it is not properly configured with thecorrect calibrat ...

Valve and Seat Grinding Seats

Valve and Seat Grinding Seats

Valve Measurement and Reconditioning OverviewProper valve service is critical to engine performance.Therefore, all detailed measurement procedures must be followed toidentify components that are out o ...

Other materials:

Hood Front Molding Replacement (Terrain) Hood Assembly

Hood Front Molding ReplacementCalloutComponent NamePreliminary ProcedureOpen and suitably support the hood assembly.1Hood Front Molding Nut (Qty-:2)Caution:Refer toFastener Caution.Tighten4.7-Y(40-lb-in)2Hood Front Molding Retainer Clip (Qty-:11)ProcedureEnsure all of the foam gaskets are in place a ...