Chevrolet Equinox Service Manual: Thread Inserts

General Purpose Thread Repair Kits.

These kits are available commercially.

Repair Procedure

Warning:Refer toSafety Glasses Warning.

Note:Refer to the thread repair kit manufacturer's instructionsregarding the size of the drill and tap to use.

Avoid any buildup of chips. Back out the tap every few turnsand remove the chips.

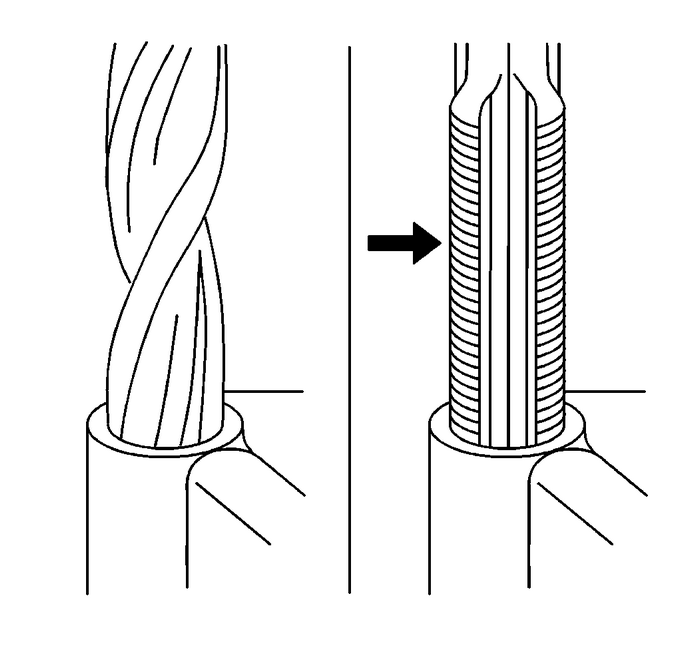

Determine the size, the pitch, and the depth of the damagedthread. If necessary, adjust the stop collars on the cutting tooland tap to the required depth.Drill out the damaged threads. Clean out any chips.Lubricate the tap with light engine oil. Tap the hole. Cleanthe threads.

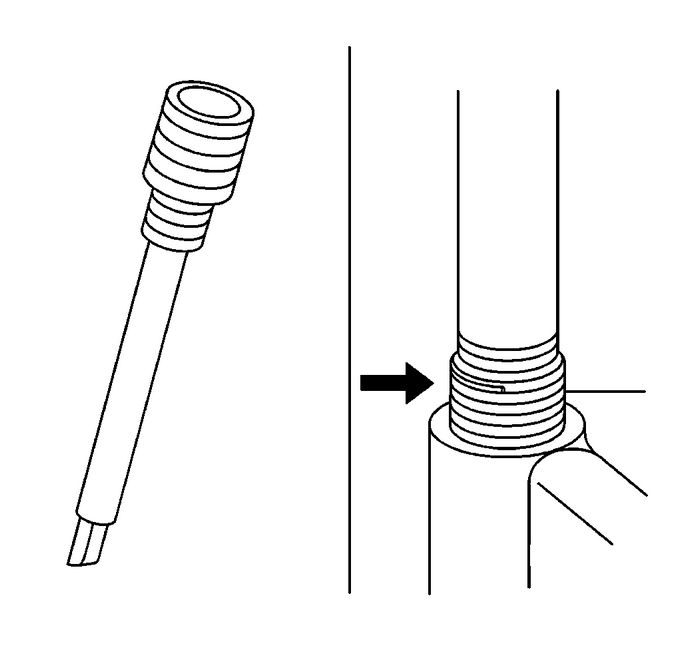

Thread the thread insert onto the mandrel of the installer.Engage the tang of the insert onto the end of the mandrel.

Note:The insert should be flush to one turn below thesurface.

Lubricate the insert with light engine oil, except wheninstalling in aluminum and install the insert.If the tang of the insert does not break off when backing outthe installer, break the tang off with a drift. Fluid and Lubricant Recommendations

Fluid and Lubricant Recommendations

Fluid and Lubricant RecommendationsUsageFluid/LubricantEngine OilUse only engine oil licensed to the dexos1 specfication, or equivalent, of the properSAE viscosity grade. ACDelco dexos1 Synthetic Blen ...

OnStar®

OnStar®

If equipped, this vehicle has a comprehensive, in-vehicle system that can connectto a live Advisor for Emergency, Security, Navigation, Connection, and DiagnosticServices. SeeOnStar Overview. ...

Other materials:

Test Probe Caution

Caution:Do not insert test equipment probes (DMM etc.) into any connector or fuse block terminal.The diameter of the test probes will deform most terminals. A deformed terminal willcause a poor connection, which will result in a system failure. Always use the J-35616-FGM Approved Terminal Release To ...