Chevrolet Equinox Service Manual: Electronic Vibration Analyzer (EVA) Description and Operation

Special ToolsEL-38792-25Inductive Pickup Timing LightEL-38792-AElectronic Vibration Analyzer-2(EVA-2)

For equivalent regional tools, refer toSpecial Tools and Equipment.

TheEL-38792-AElectronic Vibration Analyzer-2(EVA-2), is a 12–volt powered hand-held device, similarto a scan tool, which receives input from an attached vibrationsensor or accelerometer and displays the most dominate inputfrequency(ies) (up to three) on its liquid crystal display. Thevibration concern frequency(ies) are obtained through the use oftheEL-38792-AElectronic Vibration Analyzer-2(EVA-2)while following the Vibration Analysis Diagnostic Tables.The frequency(ies) obtained, when applied to the Vibration AnalysisDiagnostic Tables, are used as a primary input to help determinethe source of the vibration concern.

EVA Vibration SensorTheEL-38792-AElectronic Vibration Analyzer-2(EVA-2)vibration sensor incorporates a 6.1-m(20-ft) cord, that allows the sensor to be placed onvirtually any component of the vehicle where a vibration concern isfelt.

TheEL-38792-AElectronic Vibration Analyzer-2(EVA-2)contains 2 sensor input ports which can be activatedindividually to allow for 2 individual vibration sensor inputs. Thevibration sensors can then be placed in 2 different locations inthe vehicle and their individual inputs can be read without havingto stop a test, move the sensor and resume the test. The use of 2vibration sensors can help in more quickly finding and recording anaccurate frequency of the vibration concern, and in more quicklymaking comparisons between 2 different areas of a single component,or a vehicle system, during the diagnostic process.

EVA Vibration Sensor Placement

Proper placement of theEL-38792-AElectronic Vibration Analyzer-2(EVA-2)vibration sensor (accelerometer) is critical to ensurethat proper vibration readings are obtained by theEL-38792-AElectronic Vibration Analyzer-2(EVA-2). The vibration sensor should be placed on the specificvehicle component identified as being the most respondent to thevibration. If no component has been identified, install the sensorto the steering column as a starting point.

EVA Vibration Sensor-to-Component Attachment

Note:TheEL-38792-AElectronic Vibration Analyzer-2(EVA-2)vibration sensor must be attached to vehicle components inthe manner indicated in order to achieve accurate frequencyreadings of the vibration disturbance.

The vibration sensor of theEL-38792-AElectronic Vibration Analyzer-2(EVA-2)is designed to pickup disturbances which primarily occurin the vertical plane, since most vibrations are felt in that sameup-and-down direction. TheEL-38792-AElectronic Vibration Analyzer-2(EVA-2)vibration sensor is therefore directional sensitive andmust be attached to vehicle components such that the side of thesensor marked UP is always facing upright and the sensor body is asclose to horizontal as possible. The sensor must be installed inthe exact same position each time tests are repeated or comparisonsare made to other vehicles.

TheEL-38792-AElectronic Vibration Analyzer-2(EVA-2)vibration sensor can be attached to vehicle components invarious ways. For non-ferrous surfaces, such as the shroud of asteering column, the sensor can be attached using putty, or hookand loop fasteners. For ferrous surfaces, the sensor can beattached using a magnet supplied with the sensor.

EVA Software CartridgeTheEL-38792-AElectronic Vibration Analyzer-2(EVA-2)uses a software cartridge, the GE-38792-60,which provides various information to theEL-38792-AElectronic Vibration Analyzer-2(EVA-2). The GE-38792-60 provides theEL-38792-AElectronic Vibration Analyzer-2(EVA-2)with an additional feature which can be selected andutilized to assist in diagnosing vibration concerns.

Note:The Auto-Mode function of theEL-38792-AElectronic Vibration Analyzer-2(EVA-2)cartridge, GE-38792-60, is designed to be usedin SUPPORT of the Vibration Analysis Diagnostic Tables ONLY.

This support-feature is available through theEL-38792-AElectronic Vibration Analyzer-2(EVA-2)Auto-Mode function. When selected, theEL-38792-AElectronic Vibration Analyzer-2(EVA-2)will prompt the user to select which one of 2 vehiclesystems (vehicle speed or engine speed), is the SUSPECTED source ofthe vibration concern. Using the inputted vehicle data parametersalong with the most dominate vibration frequency obtained, it willidentify a SUSPECTED source of the vibration concern, such asfirst-order tire and wheel. This can be a useful feature when usedin conjunction with the Vibration Analysis Diagnostic Tables, toconfirm results obtained through the diagnostic process.

EVA Smart Strobe FunctionTheEL-38792-AElectronic Vibration Analyzer-2(EVA-2)can be used to identify some rotating components/systemswhich exhibit imbalance IF the component rotational speed is thedominant frequency of the vibration concern. TheEL-38792-AElectronic Vibration Analyzer-2(EVA-2)is equipped with a strobe light trigger wire which can beused with an inductive pickup timing light,EL-38792-25Inductive Pickup Timing Light, or equivalent included with theGE-38792-25–KIT, or available separately.Using the Smart Strobe function enables the user to input thevibration frequency to which the strobe will flash. By marking thesuspected rotating component, such as a pulley, adjusting thestrobe frequency to match the dominant vibration frequency at theengine RPM noted during diagnosis, and then operating the engine atthat specific RPM, the mark on the object will appear to bestationary if that object is imbalanced.

EVA Strobe Balancing FunctionTheEL-38792-AElectronic Vibration Analyzer-2(EVA-2)can be used to identify the light spot on a propellershaft IF the propeller shaft rotational speed is the dominantfrequency of the vibration concern. TheEL-38792-AElectronic Vibration Analyzer-2(EVA-2)is equipped with a strobe light trigger wire which can beused with an inductive pickup timing light,GE-38792-25Inductive Pickup Timing Light, or equivalent included with theJ-38792-25–KIT, or available separately, andin conjunction with theEL-38792-AElectronic Vibration Analyzer-2(EVA-2)vibration sensor to identify the light spot on a propellershaft and to help in making a determination as to when propellershaft balance is obtained.

Averaging/Non-Averaging ModesThe EVA provides 2 modes of displaying the most dominatefrequencies which the EVA vibration sensor (accelerometer) detects;averaging and non-averaging (instantaneous).

The averaging mode uses multiple vibration samples taken overa period of time and then displays the most dominant frequencieswhich have been averaged-out. Using the averaging mode minimizesthe distractions caused by a sudden vibration frequency beingdisplayed that is not related to the concern vibration, such asfrom pot holes or from uneven road surfaces.

The non-averaging (instantaneous) mode is more sensitive tovibration disturbances than the averaging mode. Using thenon-averaging mode will generate instantaneous frequency displayswhich are not averaged across multiple samples over a period oftime; the specific vibration frequencies that occur at a specificmoment during diagnostic testing will be displayed at that moment.The non-averaging (instantaneous) mode is useful when measuring avibration disturbance that exists for only a short period of timeor during acceleration/deceleration testing.

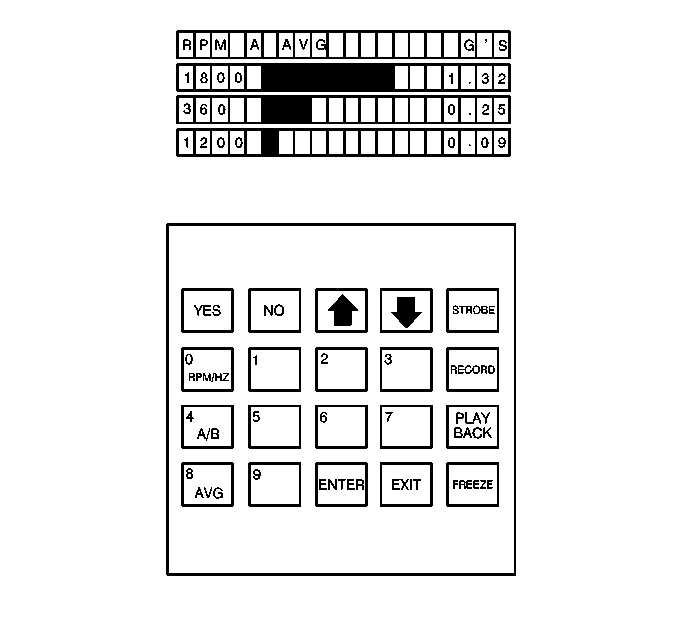

When operating the EVA in the averaging mode along with theAuto Mode, “A” will be displayed along the topof the screen to the left of the vibration sensor input port beingused. When operating the EVA in the averaging mode and the ManualMode, “AVG” will be displayed along the topcenter of the screen.

When operating the EVA in the non-averaging (instantaneous)mode along with the Auto Mode, “I” will bedisplayed along the top of the screen to the left of the vibrationsensor input port being used. When operating the EVA in thenon-averaging (instantaneous) mode and the Manual Mode, the topcenter of the screen will be blank.

EVA Display

The most dominant input frequencies, up to three, receivedfrom theEL-38792-AElectronic Vibration Analyzer-2(EVA-2)vibration sensor, are displayed in descending order ofamplitude strength.

The frequency readings are displayed along the left side ofthe screen, followed to the right by either a bar graph or thesuspected source of the vibration – depending upon themode selected, then the amplitude reading for each frequency alongthe right side of the screen. The top row of the screen indicatesthe units of measure being displayed for the frequencies along theleft side and for the amplitudes along the right side. The top rowalso indicates the vibration sensor input port which was selectedon the keypad (A or B) and which mode was selected: averaging ornon-averaging (instantaneous).

The frequency(ies) can be displayed in either revolutions perminute (RPM) or revolutions per second; Hertz (Hz). The selecteddisplay type (RPM or Hz) will be indicated at the left side of thescreen, above the frequency readings.

When the AUTO MODE function is not in use, a bar graph isdisplayed next to each frequency to provide a quick visualindication of the relative amplitude strength.

When the AUTO MODE function is being used, the suspectedsource of the vibration is displayed next to each frequency toprovide support to the diagnostic process.

The actual amplitude strength of each frequency is displayedat the right side of the screen and shown in G's-of-accelerationforce.

Terminal Removal

Terminal Removal

Special ToolsEL-38125-550 Terminal Release Tool KitEL-38125-580 Terminal Release Tool KitEL-35616 Terminal Test Probe KitFor equivalent regional tools, refer toSpecial Tools.Note:All repairs near the ...

Measuring Voltage Drop

Measuring Voltage Drop

Special Tools EL–39200 Digital Multimeter (DMM)For equivalent regional tools, refer toSpecial Tools.Caution:Refer toTest Probe Caution.The following procedure determines the difference in voltage po ...

Other materials:

Towing the Vehicle

Caution:Incorrectly towing a disabled vehicle may cause damage. The damage would not be coveredby the vehicle warranty. Do not lash or hook to the chassis components — includingthe front and rear subframes, suspension control arms, and links — during towing andrecovery of a disabled vehicle, or ...