Chevrolet Equinox Service Manual: Crankshaft Balancer Installation Engine Block Cylinder Block Crankshaft

Special ToolsEN 41998-B Crankshaft Balancer InstallerEN 45059 Angle MeterEN 46106 Engine Flywheel Holding Tool

For equivalent regional tools, refer toSpecial Tools.

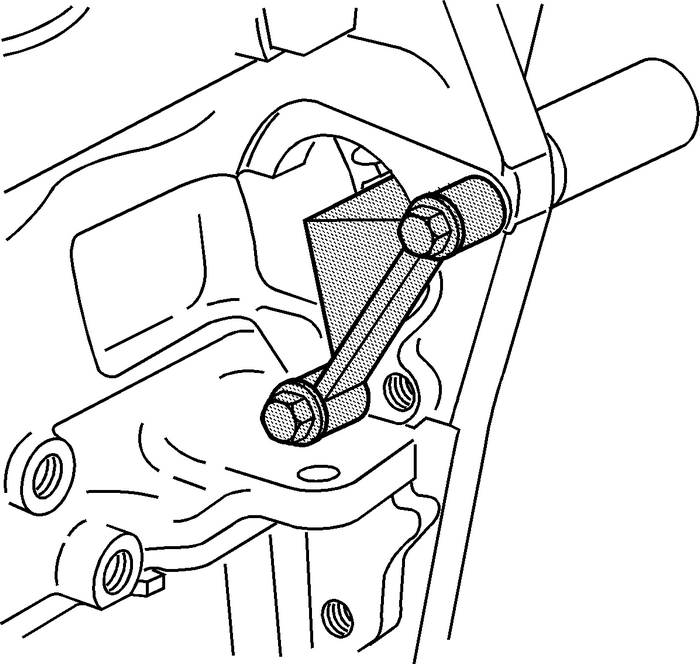

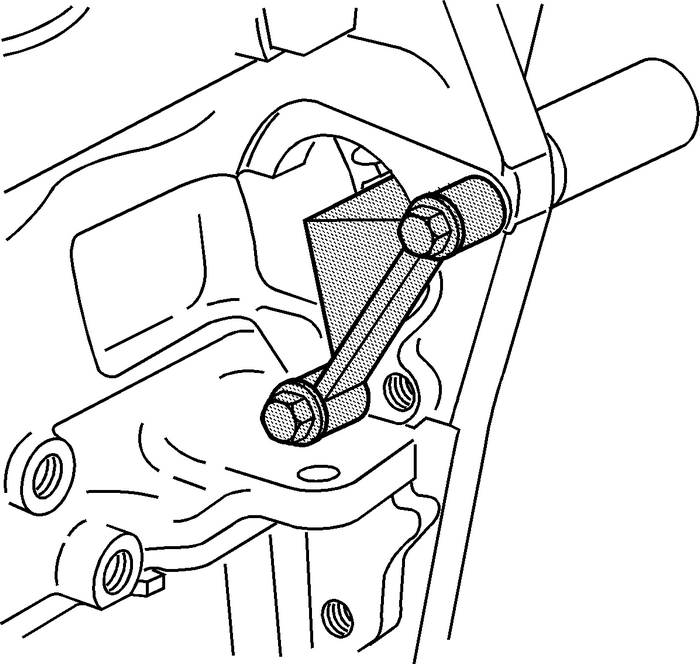

The EN 46106 toolmust be installed onto the flywheel.Use the EN 41998-B installer, nut, bearing and washer to install the crankshaft balancer.

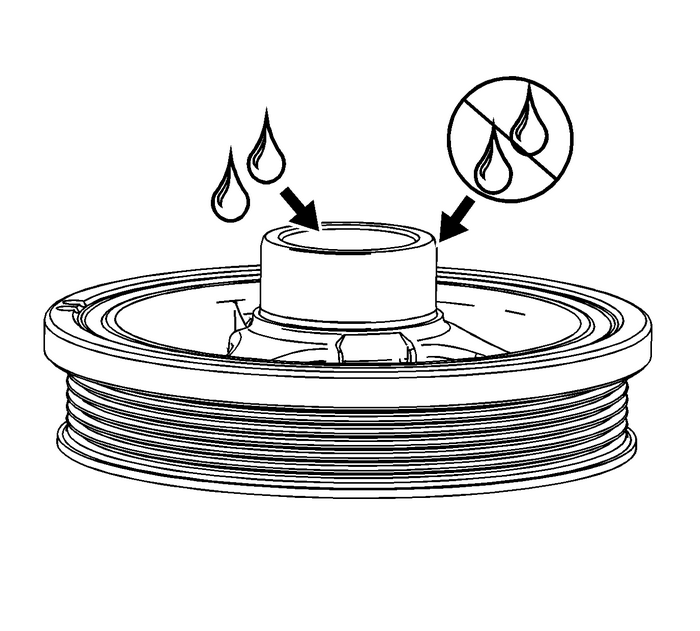

Note:Do not lubricate the crankshaft front oil seal or crankshaft balancer sealing surfaces.The crankshaft balancer is installed into a dry seal.

Apply lubricant to the inside of the crankshaft balancer hub bore.

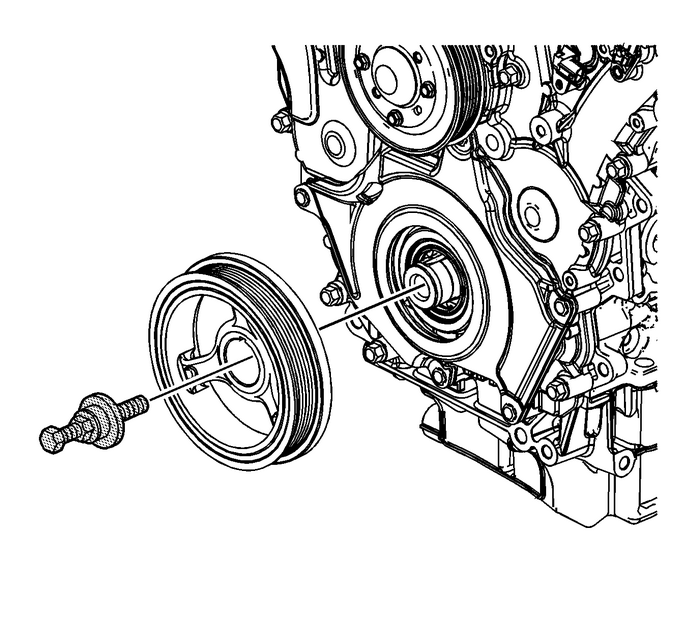

Place the crankshaft balancer in position on the crankshaft.Thread the EN 41998-B installerin the crankshaft. Ensure you engage at least 10-threads of the EN 41998-B installerbefore pressing the crankshaft balancer in place.Push the crankshaft balancer into position by tightening the nut on the J 41998-B installeruntil the large washer bottoms out on the crankshaft end.Remove the EN 41998-B installer.

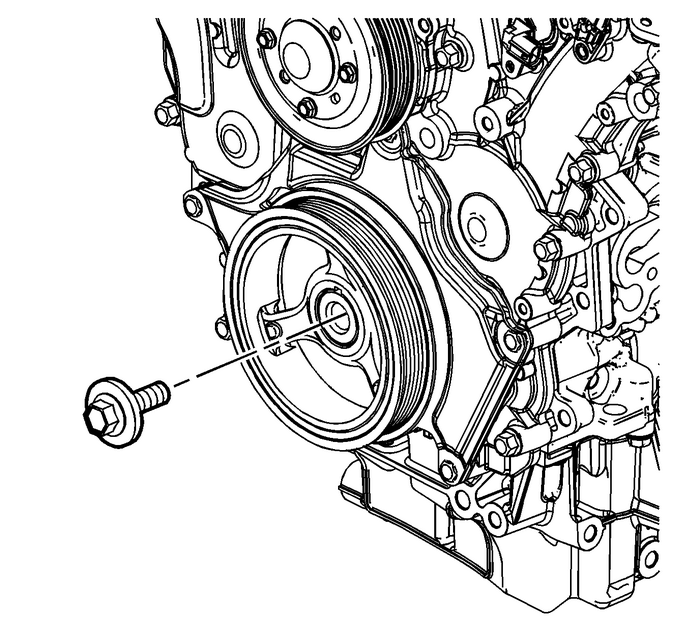

Caution:This vehicle is equipped with torque-to-yield or single use fasteners. Install a NEWtorque-to-yield or single use fastener when installing this component. Failure toreplace the torque-to-yield or single use fastener could cause damage to the vehicleor component.

Install the NEW crankshaft balancer bolt.Caution:Refer toFastener Caution.

Tighten the crankshaft balancer bolt.Tighten the crankshaft balancer bolt to 100-Y (74-lb-ft).Tighten the crankshaft balancer bolt an additional 150-degreesusing the EN 45059 meter.

Remove the EN 46106 tool.

Valve Stem Oil Seal and Valve Spring Replacement - Left Side Valvetrain Valve Actuating Assembly

Valve Stem Oil Seal and Valve Spring Replacement - Left Side Valvetrain Valve Actuating Assembly

Special ToolsEN-39313 Spark Plug Port AdapterEN-46106 Flywheel Holding ToolEN-46110 On-Vehicle Valve Spring CompressorEN-46116 Valve Stem Seal Remover/InstallerFor equivalent regional tools, refer toS ...

Crankshaft Rear Oil Seal Replacement Engine Block Seals and Gaskets

Crankshaft Rear Oil Seal Replacement Engine Block Seals and Gaskets

Special ToolsEN-42067Rear Main Seal InstallerFor equivalent regional tools, refer toSpecial Tools.Removal ProcedureRemove the flywheel. Refer toEngine Flywheel ReplacementNote:Do not damage the outsid ...

Other materials:

Control Valve Channel Plate - Upper Body Spacer Plate Side Automatic Transmission Unit

Control Valve Channel Plate– Upper Body Spacer Plate Side(2)Line(4)Converter Feed(7)Cooler Feed(9)Regulated Apply(10)Compensator Feed(11)Actuator Feed Limit(13)PCS Line(14)PCS R1/456 Clutch(15)Solenoid 1(16)Solenoid 2(17)CSV2 Enable(18)CSV3 Enable(19)R1/456 Clutch Feed(23)PCS 35 Reverse Clutch(24) ...